At its core, the primary advantage of Teflon (PTFE) in anti-corrosion applications is its near-total chemical inertness, making it resistant to almost all industrial chemicals and solvents. This is complemented by its ability to withstand extreme temperatures, its non-stick surface that prevents residue buildup, and its excellent electrical insulation properties, creating a uniquely robust barrier against degradation.

In the relentless fight against corrosion, most materials aim to slow down an inevitable process. Teflon, however, changes the rules. Its unique combination of chemical, thermal, and physical properties creates a fundamentally non-reactive shield, preventing corrosive attacks from starting in the first place.

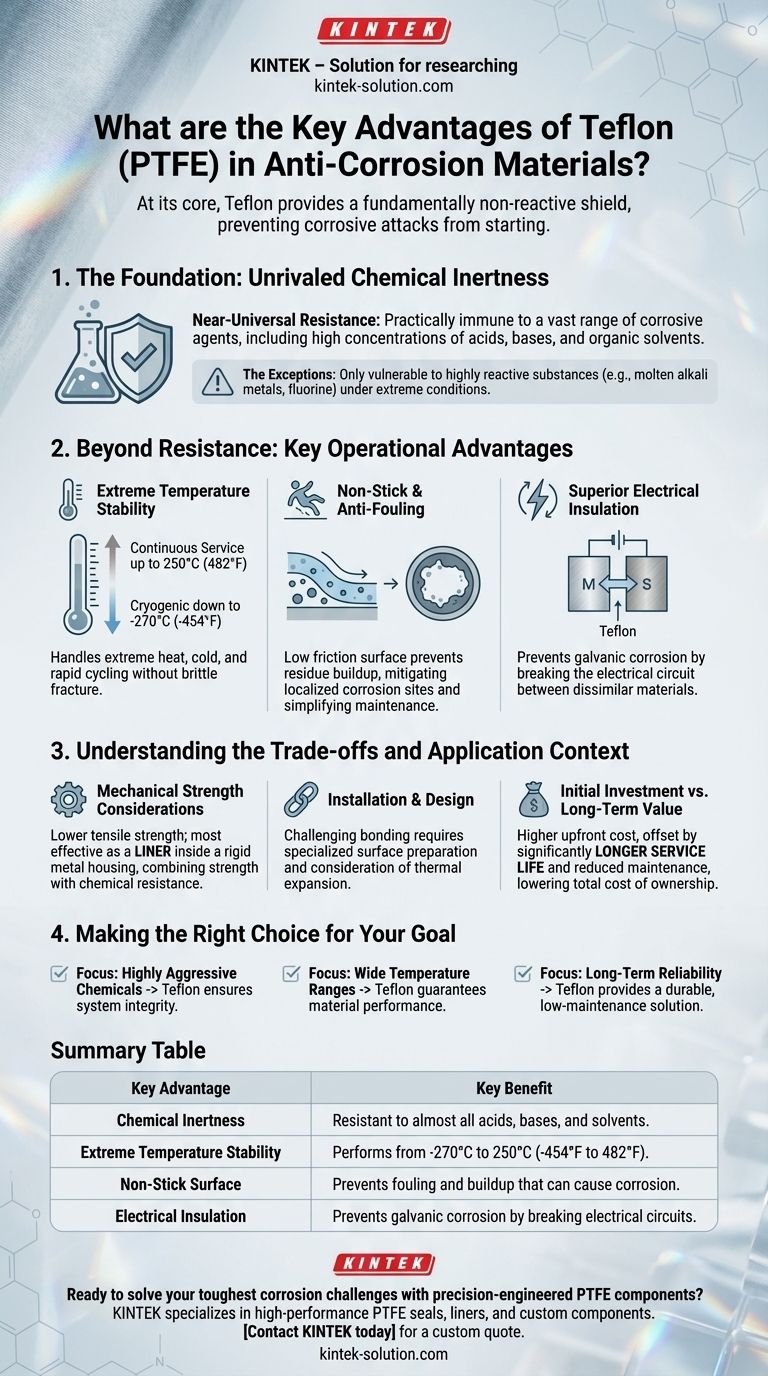

The Foundation: Unrivaled Chemical Inertness

The most significant attribute of Teflon is its lack of reactivity. This property makes it the material of choice for the most demanding chemical environments.

Near-Universal Resistance

Teflon is practically immune to a vast range of corrosive agents. This includes high concentrations of acids like sulfuric and nitric acid, bases, strong oxidants, and nearly all organic solvents.

This inertness ensures that the material does not degrade, swell, or weaken when exposed to aggressive process fluids, preserving the integrity of the system it protects.

The Exceptions That Prove the Rule

To be precise, Teflon's only known vulnerabilities are to highly reactive substances like molten alkali metals (e.g., sodium), elemental fluorine, and certain aromatic compounds under specific high-temperature and pressure conditions.

The extreme nature of these exceptions highlights just how stable Teflon is in all other environments, solidifying its status as a premier anti-corrosion material.

Beyond Resistance: Key Operational Advantages

Teflon's effectiveness isn't just about passive chemical resistance. Its other physical properties actively contribute to its performance and longevity in harsh operational settings.

Extreme Temperature Stability

Teflon maintains its integrity across an exceptionally wide thermal range. It can handle continuous service temperatures up to 250°C (482°F) and remains functional at cryogenic temperatures as low as -270°C (-454°F).

This allows it to be used in processes involving extreme heat, cold, or rapid temperature cycling without becoming brittle or degrading.

Preventing Buildup with Non-Stick Surfaces

Teflon is famous for its low coefficient of friction and non-stick nature. In industrial applications, this prevents media from adhering to the surface.

This is a critical anti-corrosion feature because it mitigates fouling and buildup, which can create localized sites for corrosion to begin under the deposits. It also simplifies cleaning and maintenance.

Superior Electrical Insulation

As an excellent electrical insulator, Teflon can prevent galvanic corrosion. This type of corrosion occurs when two dissimilar metals are in electrical contact in the presence of an electrolyte.

By lining pipes or separating flanges with Teflon, you break the electrical circuit, effectively neutralizing this common and destructive corrosion mechanism.

Understanding the Trade-offs and Application Context

While its properties are exceptional, understanding how to apply Teflon is key to success. Its primary limitations are not chemical, but mechanical.

Mechanical Strength Considerations

Teflon is a relatively soft material with lower tensile strength and abrasion resistance compared to metals. It is not intended to be a primary structural component.

This is why it is most effective when used as a liner inside a rigid metal housing, such as in Teflon-lined valves, pipes, and vessels. This design combines the structural strength of steel with the chemical resistance of Teflon.

Installation and Design Complexity

Because of its non-stick properties, bonding Teflon to other substrates can be challenging and requires specialized surface preparation techniques like chemical etching.

The design of lined components must account for Teflon's thermal expansion rate, which differs from that of metal, to ensure the liner remains secure during temperature fluctuations.

Cost as an Initial Investment

Materials and components featuring Teflon lining often have a higher upfront cost compared to standard alloy or metal options.

However, this initial expense is frequently offset by a significantly longer service life, reduced maintenance, and prevention of costly failures and downtime, leading to a lower total cost of ownership.

Making the Right Choice for Your Goal

Selecting Teflon is a decision based on prioritizing performance and long-term reliability in environments where other materials would fail.

- If your primary focus is handling highly aggressive chemicals: Teflon's near-universal inertness makes it the definitive choice for ensuring system integrity and safety.

- If your primary focus is process stability across wide temperature ranges: Its exceptional thermal resistance guarantees material performance from cryogenic lows to high-heat industrial processes.

- If your primary focus is long-term reliability and minimizing downtime: The combined benefits of chemical, thermal, and non-stick properties lead to a durable, low-maintenance solution that protects your investment.

Ultimately, choosing Teflon is an investment in unparalleled chemical resilience and operational peace of mind.

Summary Table:

| Key Advantage | Key Benefit |

|---|---|

| Chemical Inertness | Resistant to almost all acids, bases, and solvents. |

| Extreme Temperature Stability | Performs from -270°C to 250°C (-454°F to 482°F). |

| Non-Stick Surface | Prevents fouling and buildup that can cause corrosion. |

| Electrical Insulation | Prevents galvanic corrosion by breaking electrical circuits. |

Ready to solve your toughest corrosion challenges with precision-engineered PTFE components?

KINTEK specializes in manufacturing high-performance PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. We combine material expertise with precision production to deliver solutions that ensure system integrity, reduce maintenance, and extend service life—from prototypes to high-volume orders.

Contact KINTEK today to discuss your application and get a custom quote.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity

- What environmental resistances does PTFE offer? Unmatched Durability for Harsh Conditions

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers

- What is PTFE commonly known as and what type of material is it? A Guide to High-Performance PTFE Properties

- What are the additional properties of PTFE? Beyond Non-Stick: Extreme Chemical, Thermal & Electrical Performance