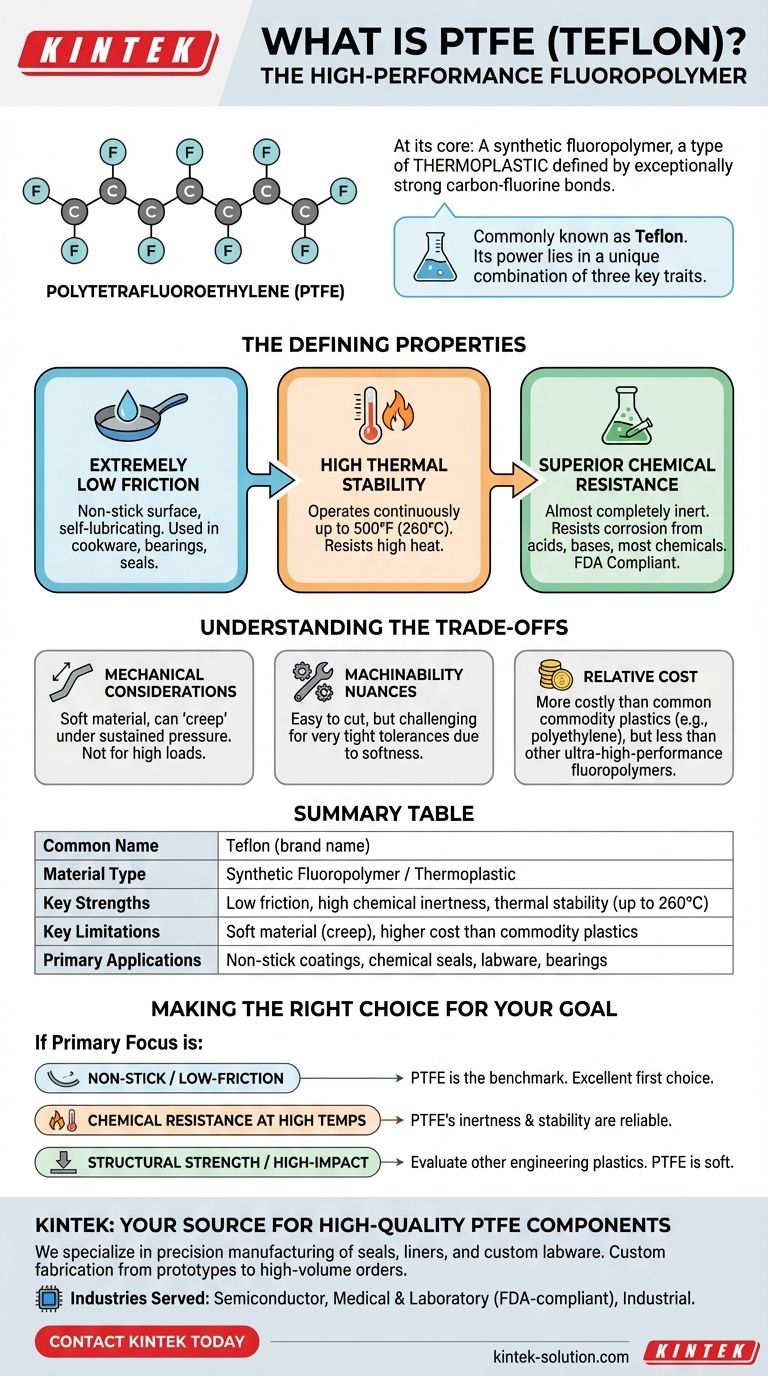

At its core, Polytetrafluoroethylene (PTFE) is a high-performance synthetic plastic most famously known by its brand name, Teflon. It is a type of fluoropolymer, a class of materials defined by exceptionally strong carbon-fluorine bonds that grant it a unique set of valuable properties.

The name Teflon is what makes PTFE famous, but its true value lies in a powerful combination of three key traits: an extremely low coefficient of friction (making it non-stick), high heat resistance, and near-total chemical inertness.

Understanding the Material: What is PTFE?

PTFE's properties are a direct result of its molecular structure. Understanding this structure is key to understanding why it behaves the way it does.

A Synthetic Fluoropolymer

The full name, Polytetrafluoroethylene, tells the story. "Poly" means it's a polymer—a long chain of repeating molecular units. "Tetrafluoroethylene" is the name of that single unit (monomer).

The "fluoro" part is critical. PTFE is a fluorocarbon-based polymer, meaning its structure is built around a chain of carbon atoms bonded to fluorine atoms.

The Source of Its Strength

The bond between carbon and fluorine is one of the strongest in organic chemistry. This immense bond strength is what gives PTFE its signature resistance to heat and chemical attack.

It is also classified as a thermoplastic, meaning it can be softened with heat and reformed without degrading, which aids in its manufacturing.

The Defining Properties of PTFE

The unique chemistry of PTFE translates into a set of high-performance characteristics that make it suitable for a wide range of demanding applications.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This is why it is used as a non-stick coating on cookware and as a self-lubricating material in bearings and seals.

High Thermal Stability

This material can operate continuously at temperatures up to 500°F (260°C). This allows it to function in high-heat environments where many other plastics would fail.

Superior Chemical Resistance

Due to its strong molecular bonds, PTFE is almost completely inert. It resists corrosion and degradation from the vast majority of chemicals, acids, and bases.

Versatility and Compliance

These properties make PTFE incredibly versatile. Its use spans from industrial applications requiring wear resistance to medical devices and food processing equipment, where its purity and FDA compliance are essential.

Understanding the Trade-offs

While its properties are impressive, no material is perfect. A true technical understanding requires acknowledging its limitations.

Mechanical Considerations

PTFE is a relatively soft material. While it has good wear resistance for low-friction applications, it is not suitable for high-load structural components, as it can deform or "creep" under sustained pressure.

Machinability Nuances

PTFE is generally easy to cut and machine. However, its softness can make holding very tight tolerances a challenge without specialized techniques and tooling.

Relative Cost

One source calls PTFE "inexpensive." This must be understood in context. It is less expensive than other ultra-high-performance fluoropolymers, but it is significantly more costly than common commodity plastics like polyethylene or polypropylene.

Making the Right Choice for Your Goal

Selecting a material requires matching its specific strengths to your primary objective.

- If your primary focus is a non-stick or low-friction surface: PTFE is the industry benchmark and an excellent first choice for its unparalleled lubricity.

- If your primary focus is chemical resistance at high temperatures: PTFE's inertness and thermal stability make it one of the most reliable options for sealing or containing corrosive media.

- If your primary focus is structural strength or high-impact resistance: You should evaluate other engineering plastics, as PTFE's softness is a significant limiting factor in load-bearing roles.

Ultimately, understanding PTFE's distinct profile of strengths and weaknesses empowers you to use it where it will truly excel.

Summary Table:

| Property | Description |

|---|---|

| Common Name | Teflon (brand name) |

| Material Type | Synthetic Fluoropolymer / Thermoplastic |

| Key Strengths | Extremely low friction, high chemical inertness, thermal stability (up to 260°C / 500°F) |

| Key Limitations | Soft material (can creep under load), higher cost than commodity plastics |

| Primary Applications | Non-stick coatings, chemical-resistant seals and liners, low-friction bearings, labware |

Need High-Quality PTFE Components?

KINTEK specializes in the precision manufacturing of PTFE components like seals, liners, and custom labware. Our expertise ensures your parts meet the exact demands of your application, leveraging PTFE's superior chemical resistance and non-stick properties.

We serve specialized industries where performance is critical:

- Semiconductor: For ultra-pure, chemical-resistant components.

- Medical & Laboratory: For FDA-compliant, inert, and reliable parts.

- Industrial: For durable seals and liners that handle corrosive media.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the right solution for your specific needs.

Contact KINTEK today to discuss your PTFE component requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How are PTFE coatings applied? A Guide to Spray, Electrostatic, and Dip-Spin Methods

- What are the key properties of PTFE relevant to troubleshooting and maintenance? Master PTFE's Strengths and Weaknesses

- What is the temperature range for PTFE's mechanical stability? From -200°C to +260°C

- What are the mechanical properties of Teflon? A Guide to Its Unique Strengths and Limitations

- How does PTFE's chemical resistance compare to other plastics? Discover the Ultimate Inert Material

- Why is PTFE important in the chemical and steel industries? Ensure Safety and Reliability in Harsh Environments

- What is the dielectric strength of PTFE and how does it vary with thickness? A Guide to Reliable Insulation Design

- What are the general characteristics of PTFE as a material? Unmatched Performance in Extreme Conditions