The primary advantages of PTFE-lined pipes are their exceptional chemical resistance and an extremely low-friction surface. This combination creates a high-performance piping system that protects both the structural pipe from corrosion and the conveyed material from contamination, making it ideal for demanding industrial applications.

A PTFE lining effectively transforms a standard, structurally sound pipe into a specialized conduit for aggressive, high-purity, or viscous fluids. It isolates the conveyed material from the pipe wall, solving critical challenges related to corrosion, contamination, and flow efficiency.

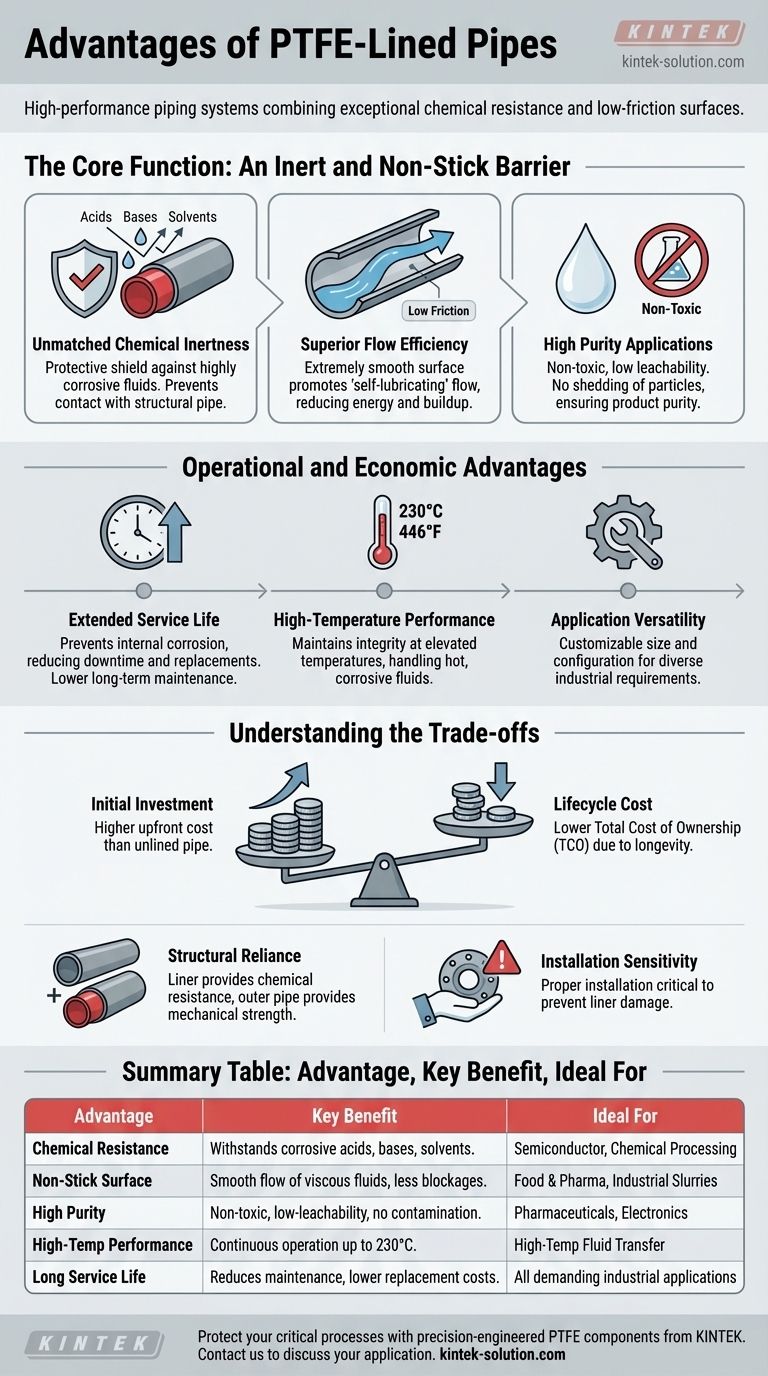

The Core Function: An Inert and Non-Stick Barrier

The fundamental value of a PTFE liner comes from its unique material properties. It acts as a continuous, seamless barrier that dramatically enhances the performance of the host pipe.

Unmatched Chemical Inertness

PTFE is one of the most chemically inert materials known. This property is the primary reason for its use in harsh environments.

The lining creates a protective shield that prevents highly corrosive fluids from ever contacting the pipe's external structure, which is typically carbon or stainless steel. This makes the system resistant to a vast range of acids, bases, and solvents.

Superior Flow Efficiency

PTFE has an exceptionally low coefficient of friction, meaning its surface is extremely smooth and non-stick.

This "self-lubricating" property ensures that materials, including viscous liquids and slurries, flow with minimal resistance. This reduces the energy required for pumping and helps prevent product buildup or blockages on the pipe walls.

High Purity Applications

For industries like pharmaceuticals, food processing, and semiconductors, preventing contamination is paramount.

PTFE is a non-toxic material with very low leachability. This means it will not shed particles or chemicals into the fluid being transported, ensuring the final product remains pure.

Operational and Economic Advantages

Beyond its core material properties, using PTFE-lined pipes provides significant long-term benefits in terms of system lifespan, operating range, and overall cost.

Extended Service Life

By preventing internal corrosion and wear, the PTFE lining dramatically extends the lifespan of the entire piping system.

This durability translates directly into reduced downtime, fewer replacements, and lower long-term maintenance costs. It is considered a cost-effective solution for critical processes.

High-Temperature Performance

PTFE maintains its integrity and protective properties at elevated temperatures.

These systems can often operate continuously at temperatures up to 230°C (446°F), allowing them to handle hot, corrosive fluids that would quickly degrade other materials.

Application Versatility

PTFE-lined pipe systems are not a one-size-fits-all product. They can be customized in size and configuration to meet the specific requirements of nearly any industrial application.

Understanding the Trade-offs

While highly effective, it's important to understand the context in which PTFE-lined pipes operate to make an informed decision.

Initial Investment vs. Lifecycle Cost

The upfront cost of a PTFE-lined pipe is typically higher than that of a standard, unlined steel or alloy pipe.

However, its superior longevity and reduced maintenance needs often result in a lower total cost of ownership over the system's life, especially in highly corrosive environments.

Structural Reliance

PTFE is a liner, not a structural material. It provides the chemical resistance, while the outer pipe (e.g., carbon steel) provides the mechanical strength and pressure rating. The two components work together as a system.

Installation Sensitivity

Proper installation is critical to the performance of any lined pipe system. Care must be taken to avoid scratching, cutting, or otherwise damaging the liner at flange connections, as this could create a path for corrosion.

Making the Right Choice for Your Goal

Your decision to use PTFE-lined pipes should be based on the specific demands of your process.

- If your primary focus is handling highly corrosive chemicals: PTFE's chemical inertness provides the most reliable long-term protection against pipe degradation.

- If your primary focus is maintaining product purity: The non-toxic and low-leaching properties of a PTFE liner are essential for food, pharmaceutical, and electronic applications.

- If your primary focus is long-term reliability and efficiency: The combination of extended service life and low-friction flow makes this a sound investment for reducing maintenance and energy costs.

Ultimately, choosing a PTFE-lined system is a strategic decision to ensure the integrity and longevity of your most critical fluid transfer operations.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Chemical Resistance | Withstands highly corrosive acids, bases, and solvents. | Semiconductor, Chemical Processing |

| Non-Stick Surface | Ensures smooth flow of viscous fluids and slurries, reducing blockages. | Food & Pharma, Industrial Slurries |

| High Purity | Non-toxic, low-leachability material prevents product contamination. | Pharmaceuticals, Electronics |

| High-Temperature Performance | Operates continuously at temperatures up to 230°C (446°F). | High-Temp Fluid Transfer |

| Long Service Life | Protects structural pipe, reducing maintenance and replacement costs. | All demanding industrial applications |

Protect your critical processes with precision-engineered PTFE components from KINTEK.

Our expertise in custom fabricating high-performance PTFE liners, seals, and labware ensures your systems achieve maximum corrosion resistance, product purity, and operational efficiency. Whether you need a prototype or high-volume production for the semiconductor, medical, or industrial sectors, we deliver reliable solutions that extend service life and reduce total cost of ownership.

Contact KINTEK today to discuss your specific application requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications