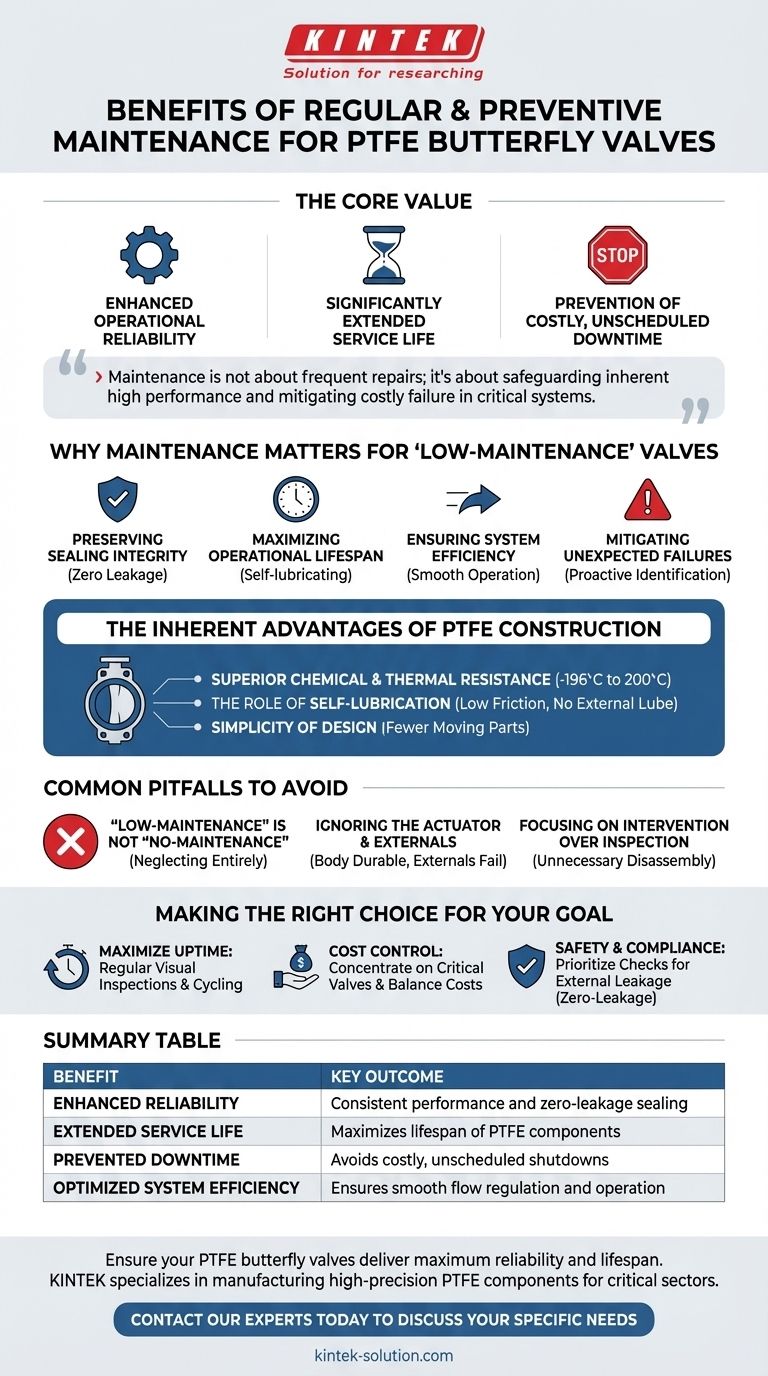

Ultimately, the primary benefits of regular and preventive maintenance for PTFE butterfly valves are enhanced operational reliability, a significantly extended service life, and the prevention of costly, unscheduled downtime. By ensuring the valve continues to operate within its design parameters, maintenance safeguards the entire system's efficiency and integrity.

While PTFE butterfly valves are rightly known for their robust, low-maintenance design, a preventive strategy is not about frequent, invasive repairs. Instead, it's about safeguarding their inherent high performance and mitigating the high cost of failure in critical systems.

Why Maintenance Matters for "Low-Maintenance" Valves

The term "low-maintenance" can be misleading. While PTFE valves require less intervention than other types, a structured maintenance plan is essential for realizing their full value and preventing system-wide disruptions.

Preserving Sealing Integrity

PTFE-lined valves are valued for their high sealing performance, often achieving zero leakage. Regular inspections ensure that the liner and disc seal remain intact, preventing loss of valuable media and protecting against environmental contamination.

Maximizing Operational Lifespan

The self-lubricating properties of PTFE and corrosion-resistant materials extend component life. However, mechanical stress, temperature cycling, and abrasive media can still cause wear over time. Preventive checks catch this degradation early.

Ensuring System Efficiency

A valve that is not seating correctly or is difficult to actuate can disrupt the flow regulation of an entire process. Maintenance verifies that the valve opens, closes, and modulates smoothly, ensuring the system operates as designed.

Mitigating Unexpected Failures

The cost of an unplanned shutdown almost always exceeds the cost of a maintenance program. Proactive maintenance identifies potential failure points before they can cause a catastrophic and expensive line stoppage.

The Inherent Advantages of PTFE Construction

Understanding the design of these valves clarifies why their maintenance needs are different. Their material properties create a foundation of reliability that maintenance aims to preserve.

Superior Chemical and Thermal Resistance

PTFE (Polytetrafluoroethylene) provides excellent resistance to strong corrosive media. This, combined with a wide operating temperature range (from -196°C to 200°C), makes these valves exceptionally durable in harsh industrial environments.

The Role of Self-Lubrication

The very low friction of the PTFE liner means the valve requires no external lubrication for smooth operation. This design feature drastically reduces routine maintenance tasks and eliminates a potential point of contamination.

Simplicity of Design

A butterfly valve’s construction is straightforward: a disc rotates on a stem to control flow. This simple mechanism has fewer moving parts to fail, making inspection and potential repairs simpler and faster than more complex valve types.

Common Pitfalls to Avoid

The primary pitfall is complacency. Assuming a "low-maintenance" component requires "no-maintenance" can lead to predictable and preventable failures.

"Low-Maintenance" is Not "No-Maintenance"

The most common mistake is neglecting these valves entirely. The robust design reduces the frequency and intensity of required maintenance, but it does not eliminate the need for periodic inspection.

Ignoring the Actuator and Externals

The valve body and liner may be incredibly durable, but the external components are not. Actuators, stem seals, and mounting hardware are often the first points of failure and must be included in any inspection routine.

Focusing on Intervention Over Inspection

Effective maintenance for PTFE valves emphasizes scheduled inspection and operational testing rather than unnecessary disassembly. The goal is to confirm proper function, not to interfere with a component that is working correctly.

Making the Right Choice for Your Goal

A successful maintenance strategy aligns with your specific operational priorities. By tailoring your approach, you can maximize the benefits of your PTFE butterfly valves.

- If your primary focus is maximizing uptime: Implement a schedule of regular visual inspections and operational cycling to catch actuation or sealing issues before they can lead to a shutdown.

- If your primary focus is cost control: Concentrate maintenance efforts on the most critical valves in your system, balancing the low cost of inspection against the very high cost of potential failure.

- If your primary focus is safety and compliance: Prioritize regular checks for any signs of external leakage, especially on valves handling hazardous media, to ensure zero-leakage performance is maintained.

A proactive maintenance approach transforms your PTFE valves from a reliable component into a guaranteed asset for long-term operational stability.

Summary Table:

| Benefit | Key Outcome |

|---|---|

| Enhanced Reliability | Consistent performance and zero-leakage sealing |

| Extended Service Life | Maximizes lifespan of PTFE components |

| Prevented Downtime | Avoids costly, unscheduled shutdowns |

| Optimized System Efficiency | Ensures smooth flow regulation and operation |

Ensure your PTFE butterfly valves deliver maximum reliability and lifespan. KINTEK specializes in manufacturing high-precision PTFE components, including seals and liners, for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services, from prototypes to high-volume orders, ensure your critical systems are supported by components built for durability. Contact our experts today to discuss your specific valve and sealing needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability