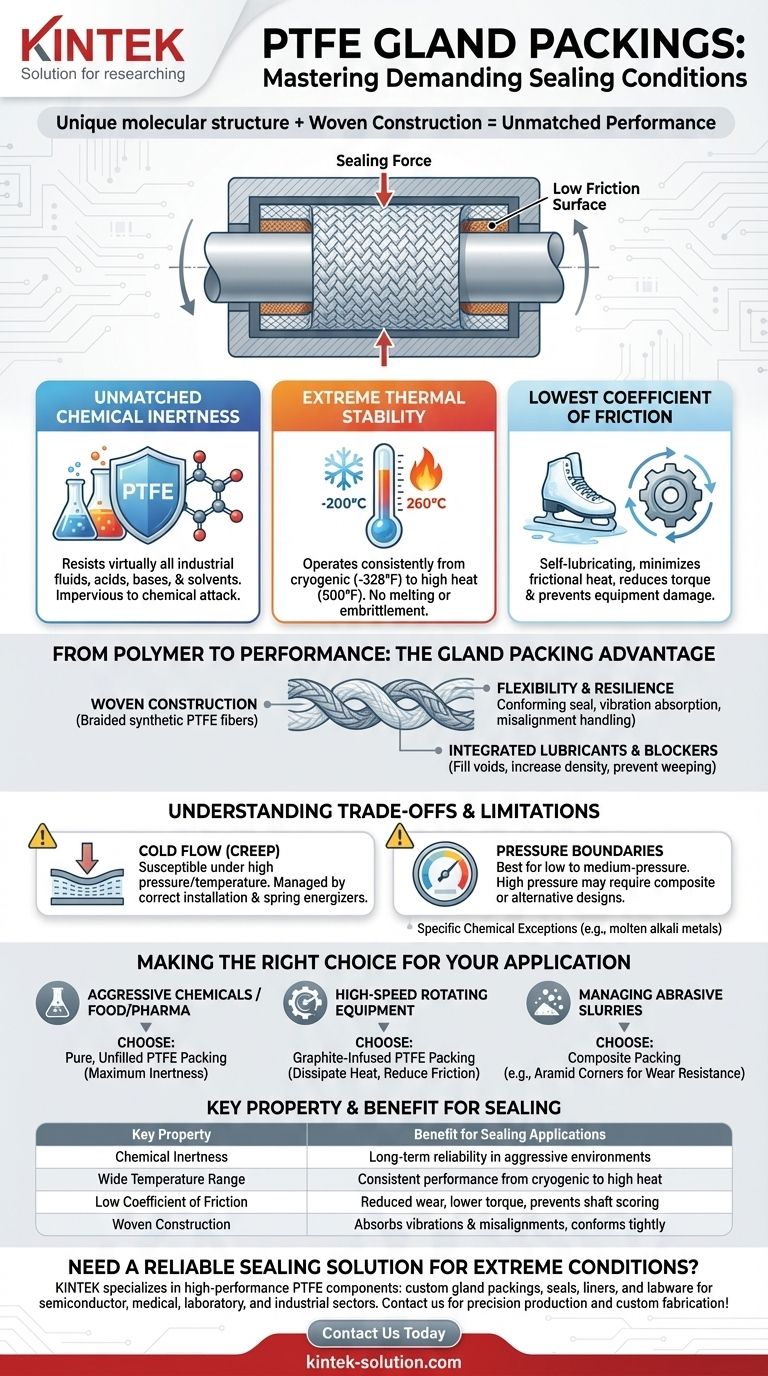

In short, PTFE gland packings are suitable for demanding sealing conditions due to their unique molecular structure, which provides an unmatched combination of chemical inertness, a vast operating temperature range, and an extremely low coefficient of friction. These inherent material properties are then enhanced by a woven construction that adds mechanical strength and resilience.

The true advantage of PTFE gland packing isn't just the raw polymer itself, but how it's engineered. The combination of PTFE's intrinsic properties with a flexible, woven structure creates a seal that is simultaneously durable, low-friction, and resistant to extreme environments where other materials would quickly fail.

The Foundation: Why PTFE is a Superior Sealing Polymer

To understand the performance of a gland packing, we must first look at its core material. Polytetrafluoroethylene (PTFE) is a fluoropolymer with a unique molecular makeup that gives it three exceptional characteristics for sealing.

Unmatched Chemical Inertness

The PTFE molecule consists of a long chain of carbon atoms completely shielded by fluorine atoms. The carbon-fluorine bond is one of the strongest in organic chemistry.

This structure makes PTFE almost universally inert. It is impervious to virtually all industrial fluids and gases, including aggressive acids, bases, and solvents that would degrade conventional elastomers and metals.

Extreme Thermal Stability

The same strong molecular bonds that provide chemical resistance also give PTFE remarkable thermal stability. It retains its critical properties across an exceptionally wide temperature range.

PTFE seals can operate consistently in conditions from cryogenic (-200°C / -328°F) up to high heat (260°C / 500°F), environments where most elastomeric seals become brittle or melt.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid material, often compared to wet ice on wet ice. This results in inherent "non-stick" and self-lubricating properties.

For sealing applications on rotating shafts or moving rods, this is critical. It minimizes frictional heat buildup, reduces torque requirements, and prevents scoring or damage to expensive equipment components.

From Polymer to Performance: The Gland Packing Advantage

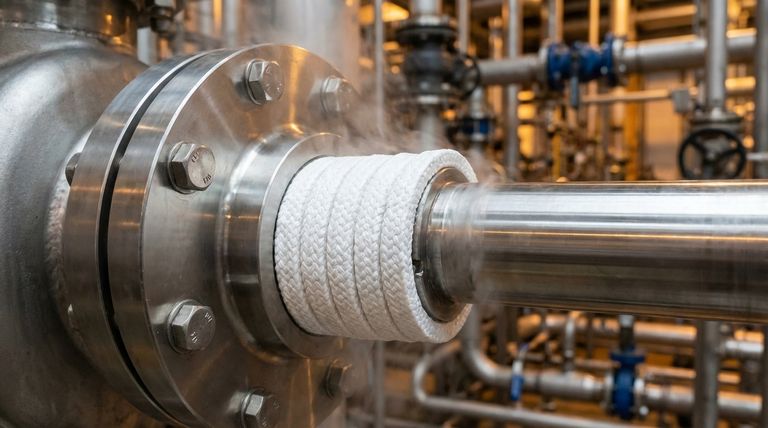

A solid ring of PTFE would be too rigid for many dynamic sealing applications. The gland packing format leverages PTFE's properties while adding mechanical resilience.

The Role of Woven Construction

PTFE gland packings are not solid blocks but are created by weaving synthetic PTFE fibers, often around a core. This braided construction provides flexibility and compressibility.

When the gland follower is tightened, the packing conforms to the stuffing box and shaft, creating a secure seal. This structure allows it to absorb minor vibrations and shaft misalignments that a rigid seal could not.

Integrated Lubricants and Blockers

During manufacturing, lubricants and blocking agents are often incorporated into the weave. These compounds fill the microscopic voids within the braid.

This enhances the seal's density, prevents "weeping" of the process fluid through the packing itself, and can further reduce the coefficient of friction for an even smoother run.

Understanding the Trade-offs and Limitations

No material is perfect for every scenario. Being a trusted advisor means acknowledging the operational boundaries of PTFE packings.

Susceptibility to Cold Flow

Under high, sustained pressure and temperature, PTFE can be prone to "creep" or "cold flow," where the material slowly deforms over time. This can lead to a loss of sealing pressure.

This is often managed through correct installation procedures and, in some designs, the use of spring energizers that provide a constant load on the seal.

Pressure Boundaries

While excellent for temperature and chemical resistance, standard PTFE packings are best suited for low and medium-pressure applications. High-pressure environments can accelerate cold flow and may require specialized composite packings or different sealing designs entirely.

Specific Chemical Exceptions

While almost universally inert, PTFE can be attacked by a very small and specific class of chemicals. These include molten alkali metals (like sodium) and some rare, highly reactive halogenated compounds at high temperatures and pressures.

Making the Right Choice for Your Application

Selecting the correct packing involves matching the specific construction to your operational goal.

- If your primary focus is aggressive chemicals or food/pharma: Choose a pure, unfilled PTFE packing to ensure maximum chemical inertness and prevent contamination.

- If your primary focus is high-speed rotating equipment: Opt for a PTFE packing infused with graphite, which acts as a lubricant to dissipate heat and further reduce friction.

- If your primary focus is managing abrasive slurries: Consider a composite packing that weaves stronger fibers, such as Aramid, into the corners or body to dramatically increase wear resistance.

By understanding both the powerful properties and the practical limits of PTFE, you can confidently apply it to achieve unparalleled reliability in your most critical sealing applications.

Summary Table:

| Key Property | Benefit for Sealing Applications |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents, ensuring long-term reliability in aggressive environments. |

| Wide Temperature Range | Performs consistently from cryogenic (-200°C) to high heat (260°C), where other materials fail. |

| Low Coefficient of Friction | Self-lubricating properties reduce wear on equipment, lower torque, and prevent shaft scoring. |

| Woven Construction | Flexible braided design absorbs vibrations and misalignments, conforming tightly to seal surfaces. |

Need a reliable sealing solution for extreme conditions? KINTEK specializes in manufacturing high-performance PTFE components, including custom gland packings, seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our precision production and custom fabrication—from prototypes to high-volume orders—ensure your equipment operates flawlessly. Contact us today to discuss how our PTFE solutions can enhance your application's reliability and efficiency!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How do Teflon FEP and PFA perform against bases? Superior Resistance for Alkaline Environments

- What chemical resistance properties do expanded PTFE gaskets have? Achieve Universal Sealing for Aggressive Chemicals

- Why is symmetry and balance important when installing PTFE gasket seals? Ensure a Perfect, Leak-Proof Seal

- What is the friction characteristic of PTFE seals? Achieve Unmatched Low-Friction Performance

- How do PTFE-lined valves benefit the environment? Prevent Pollution and Reduce Waste

- What are the uses of expanded PTFE gasketing tapes? The Ultimate Solution for Flange Sealing Problems

- What is one weakness of PTFE gaskets and sheets? Understanding Creep and Cold Flow

- What are the limitations of machining Teflon? Overcoming Burrs, Creep, and Thermal Instability