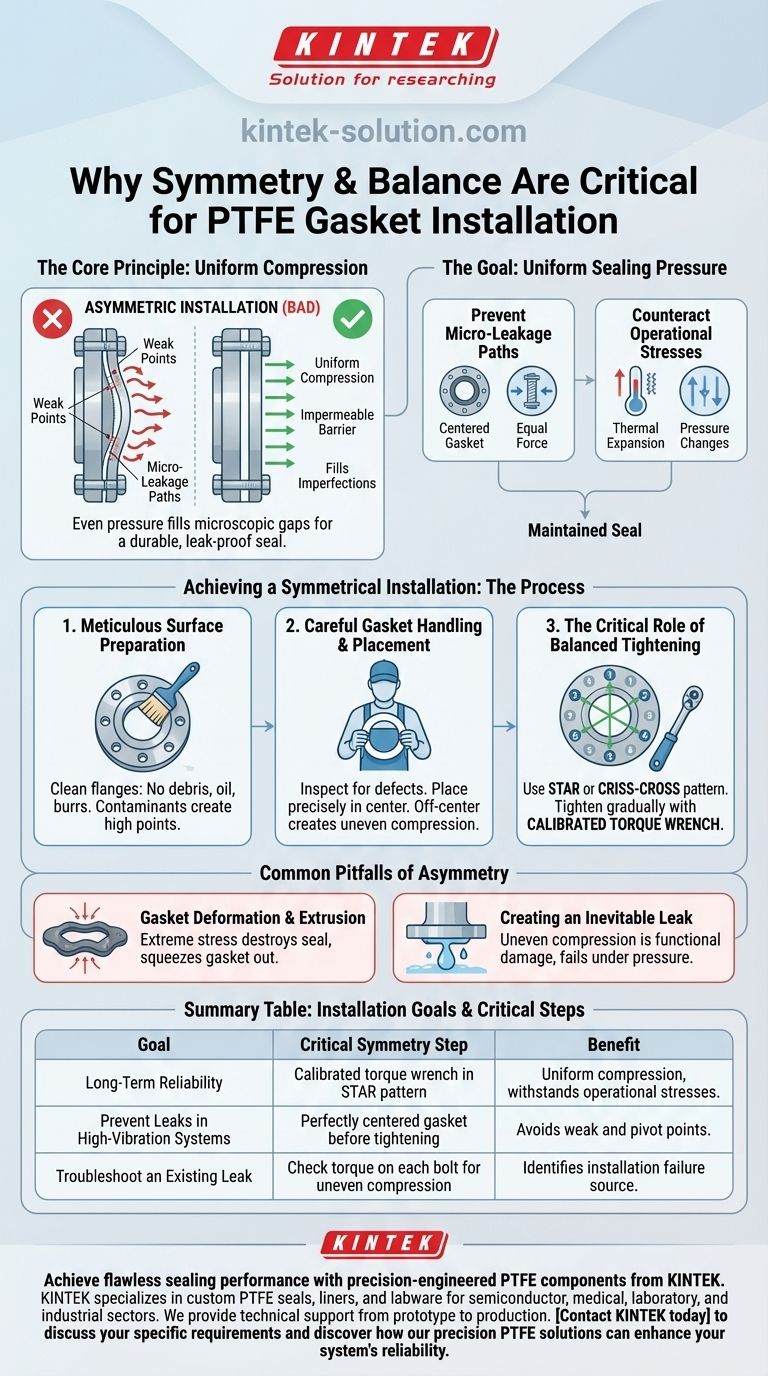

In short, symmetry and balance are critical for PTFE gasket installation because they ensure uniform compression across the entire sealing surface. This even pressure is the only way to fill microscopic imperfections in the flange faces and create a durable, leak-proof seal that can withstand changes in operating pressure and temperature.

The core principle of a successful gasket seal is not maximum tightness, but perfectly uniform compression. Asymmetry during installation creates uneven pressure, which inevitably leads to weak points and the formation of micro-leakage paths.

The Goal: Uniform Sealing Pressure

A gasket's only job is to create an impermeable barrier between two flange surfaces. These surfaces, even if they appear smooth, have microscopic imperfections. The gasket must be compressed just enough to flow into and fill these gaps.

Preventing Micro-Leakage Paths

Symmetrical installation ensures the gasket is perfectly centered and compressed evenly by each bolt. If one side is tightened more than another, it creates a high-pressure point on one side and an insufficient-pressure area on the other, providing a direct path for leaks.

Counteracting Operational Stresses

Industrial systems are not static. Fluctuations in temperature and pressure cause flanges to expand, contract, and shift slightly. A symmetrically installed gasket has a consistent "cushion" of pressure all around, allowing it to adapt to these changes and maintain the seal.

Achieving a Symmetrical Installation

Achieving balance isn't a single action but the result of a meticulous, step-by-step process. Each step builds upon the last to ensure the final compression is perfectly distributed.

Step 1: Meticulous Surface Preparation

Before the gasket is even handled, the flange surfaces must be perfectly clean and free of debris, oily residues, burrs, or weld spatter. Any contaminant on the flange face acts as a high point, preventing the gasket from seating evenly and making a uniform seal impossible.

Step 2: Careful Gasket Handling and Placement

The gasket itself must be inspected for defects and handled with care to avoid creating nicks or scratches on its sealing line. It must be placed precisely in the center of the flange. An off-center gasket guarantees uneven compression, as the bolt forces will not be distributed equally across the sealing area.

Step 3: The Critical Role of Balanced Tightening

This is the most direct application of symmetry. Bolts must be tightened gradually and in a specific sequence, typically a star or criss-cross pattern. Tightening one bolt all the way before moving to the next will warp the flange and crush the gasket on one side. Using a calibrated torque wrench is essential to apply the correct, measured force to each bolt.

Common Pitfalls of Asymmetrical Installation

Ignoring the principles of symmetry and balance directly leads to seal failure. The consequences are predictable and damaging.

Gasket Deformation and Extrusion

When tightening is unbalanced, the gasket material is subjected to extreme stress in one area. This can cause the PTFE to deform permanently or extrude, squeezing out from between the flanges. This not only destroys the seal but also damages the gasket beyond repair.

Creating an Inevitable Leak

Misalignment or incorrect tightening procedures are the primary causes of gasket leaks. An unevenly compressed gasket is functionally damaged from the moment of installation, creating a weak point that will fail under operational pressure.

How to Apply This to Your Goal

Your installation goal dictates which part of this process to emphasize.

- If your primary focus is long-term reliability: Treat surface preparation and the use of a calibrated torque wrench in a star pattern as the most critical, non-negotiable steps.

- If your primary focus is preventing leaks in a high-vibration system: Pay extra attention to ensuring the gasket is perfectly centered before you begin tightening to avoid creating a pivot point.

- If your primary focus is troubleshooting an existing leak: Your first diagnostic step should be to check the torque on each bolt to see if the compression is uneven, which often indicates the source of the failure.

Ultimately, a successful seal is a direct result of a precise and balanced installation process.

Summary Table:

| Installation Goal | Critical Symmetry Step | Benefit |

|---|---|---|

| Long-Term Reliability | Use a calibrated torque wrench in a star pattern. | Ensures uniform compression that withstands operational stresses. |

| Prevent Leaks in High-Vibration Systems | Ensure the gasket is perfectly centered before tightening. | Avoids creating weak points and pivot points for leaks. |

| Troubleshoot an Existing Leak | Check the torque on each bolt for uneven compression. | Quickly identifies the source of installation failure. |

Achieve flawless sealing performance with precision-engineered PTFE components from KINTEK.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, a perfectly installed seal is critical for safety and efficiency. KINTEK specializes in manufacturing high-quality, custom PTFE seals, liners, and labware designed for exacting applications.

We understand that the right component is only half the solution—proper installation is key. Our team can provide technical support to ensure your sealing applications are successful from prototype to high-volume production.

Contact KINTEK today to discuss your specific requirements and discover how our precision PTFE solutions can enhance your system's reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments