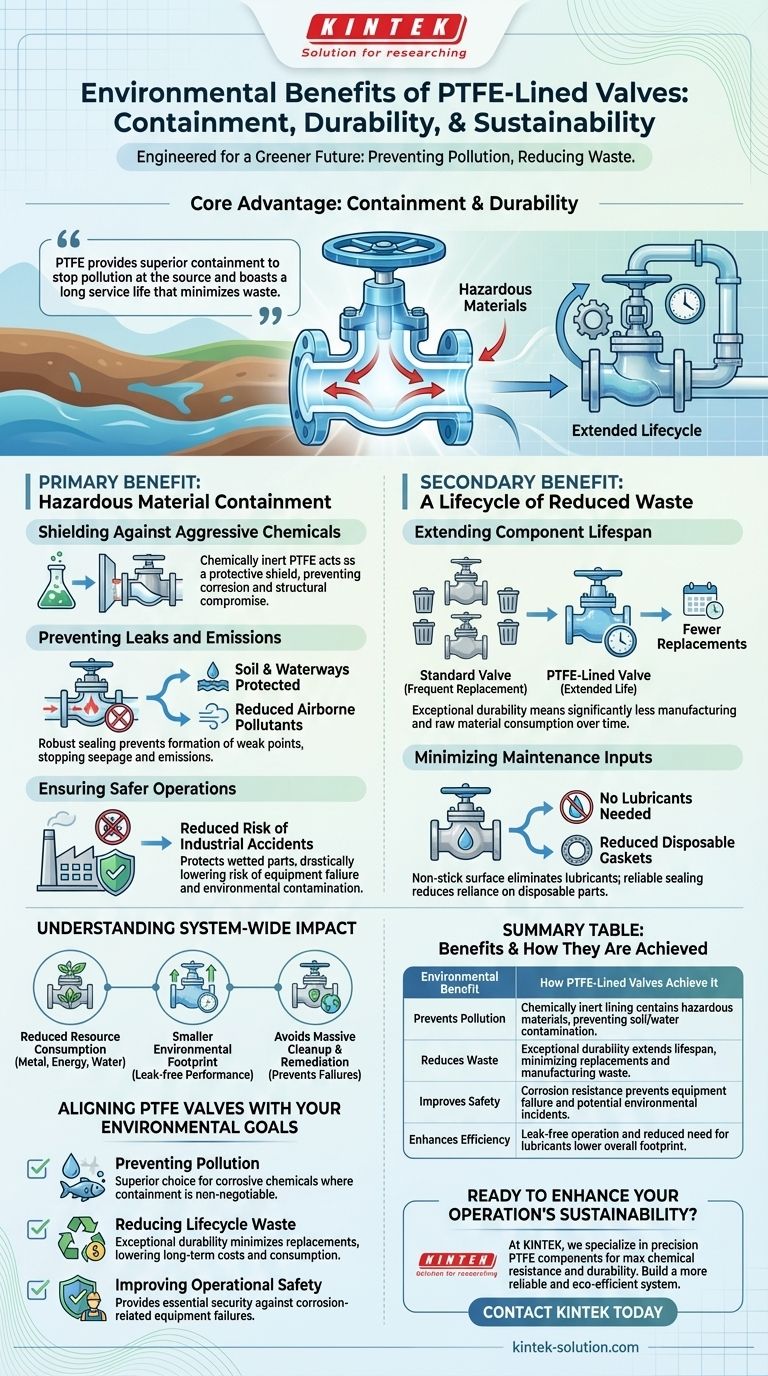

The primary environmental benefit of PTFE-lined valves stems from their exceptional chemical inertness and durability. This combination directly prevents the release of hazardous materials into soil and waterways while simultaneously reducing waste and resource consumption by extending the operational life of critical industrial components.

At its core, the environmental advantage of a PTFE-lined valve is twofold: it provides superior containment to stop pollution at the source and boasts a long service life that minimizes the waste associated with frequent repairs and replacements.

The Primary Benefit: Containment of Hazardous Materials

The most direct environmental contribution of PTFE-lined valves is their ability to prevent leaks. This is a direct result of the material's unique chemical properties.

Shielding Against Aggressive Chemicals

PTFE (Polytetrafluoroethylene) is a highly non-reactive material. It acts as an inert shield, protecting the metal body of the valve from corrosion caused by strong acids, bases, and other harsh substances.

This protective lining ensures the structural integrity of the valve is not compromised, even when handling the most aggressive media.

Preventing Leaks and Emissions

By resisting corrosion, PTFE liners prevent the formation of weak points that can lead to leaks. Their robust sealing capabilities effectively contain hazardous materials, stopping them from seeping into the ground or local waterways.

This is critical for preventing soil contamination and protecting aquatic ecosystems from industrial pollutants. Improved sealing also helps minimize the escape of airborne pollutants, supporting cleaner air quality.

Ensuring Safer Operations

Corrosion-related equipment failure is a significant cause of industrial accidents. By using PTFE to protect wetted parts, facilities can drastically reduce the risk of accidents that could lead to large-scale environmental contamination.

The Secondary Benefit: A Lifecycle of Reduced Waste

Beyond active containment, PTFE-lined valves contribute to environmental goals by fundamentally changing the maintenance and replacement cycle of industrial systems.

Extending Component Lifespan

PTFE is highly durable and resistant to wear and degradation. This longevity means valves and other lined components need to be replaced far less frequently than their unlined or less-resistant counterparts.

Fewer replacements translate directly to less manufacturing, less raw material consumption, and a significant reduction in industrial waste over the long term.

Minimizing Maintenance Inputs

The non-stick, low-friction surface of PTFE often eliminates the need for lubricants, which can be pollutants themselves.

Furthermore, the integrated and reliable sealing provided by the liner can reduce the reliance on disposable gaskets, further cutting down on operational waste.

Understanding the System-Wide Impact

To fully appreciate the environmental benefits, it's important to view these components not in isolation, but as part of a larger industrial system.

Durability Reduces Resource Consumption

The extended life expectancy of PTFE-lined components is a key factor in resource management. By designing systems that last longer, industries reduce the total volume of metal, energy, and water needed for manufacturing replacement parts.

Efficiency is an Environmental Positive

Leak-free, reliable valve performance contributes to overall system efficiency. A system that operates as designed without interruption or loss of material is inherently more resource-efficient, reducing its overall environmental footprint.

Safety as an Environmental Imperative

The connection between operational safety and environmental protection cannot be overstated. Preventing a single major corrosion-related failure avoids not only the immediate environmental damage but also the massive resource expenditure required for cleanup and remediation.

Aligning PTFE Valves with Your Environmental Goals

Choosing the right components is a critical part of responsible industrial design. Your specific goals will determine where PTFE-lined valves offer the greatest advantage.

- If your primary focus is preventing pollution: PTFE-lined valves are a superior choice for applications involving corrosive or hazardous chemicals where containment is non-negotiable.

- If your primary focus is reducing lifecycle waste: The exceptional durability of these valves minimizes the need for replacements, making them ideal for lowering long-term resource consumption and maintenance costs.

- If your primary focus is improving operational safety: The corrosion resistance of PTFE provides an essential layer of security against equipment failures that could lead to catastrophic environmental releases.

Ultimately, selecting materials based on their ability to endure their intended service environment is a cornerstone of sustainable industrial practice.

Summary Table:

| Environmental Benefit | How PTFE-Lined Valves Achieve It |

|---|---|

| Prevents Pollution | Chemically inert lining contains hazardous materials, preventing soil and water contamination. |

| Reduces Waste | Exceptional durability extends valve lifespan, minimizing replacements and manufacturing waste. |

| Improves Safety | Corrosion resistance prevents equipment failure and potential large-scale environmental incidents. |

| Enhances Efficiency | Leak-free operation and reduced need for lubricants lower the overall environmental footprint. |

Ready to enhance your operation's sustainability and safety with high-performance PTFE components?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, labware, and custom-fabricated valves—for the semiconductor, medical, laboratory, and industrial sectors. Our components are engineered for maximum chemical resistance and durability, directly contributing to your environmental goals by preventing leaks and reducing waste.

Let us help you build a more reliable and eco-efficient system. Contact KINTEK today to discuss your specific needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What temperature ranges can FEP and PTFE encapsulated O-rings withstand? A Guide to Extreme Environment Sealing

- What industries commonly use PTFE Bellows and for what purposes? Critical Applications in Chemical & Semiconductor

- What are the benefits of 15% graphite-filled PTFE bushings? Enhance Wear Resistance & Thermal Performance

- What are the physical characteristics of PTFE O-rings? The Ultimate Guide to PTFE Seal Properties

- What are the differences between Teflon and rubber sealed bearings? Choose the Right Seal for Speed or Protection

- How does PTFE compare to metals in CNC machining? Choose the Right Material for Your Application

- What are the minimum and maximum sizes for machining PTFE parts? Design for Success with No Universal Limits

- What are the cost and supply challenges associated with PTFE laminates? Navigating High Costs and Complex Supply Chains