At its core, expanded PTFE (ePTFE) gasketing tape is a highly versatile sealing material used to create custom, form-in-place gaskets directly on a flange. Its primary uses range from emergency field repairs on industrial pipelines to sealing large, complex, or damaged flange surfaces in chemical processing, oil and gas, and even on fragile materials like plastic or glass.

The fundamental value of ePTFE gasketing tape lies in its unique combination of extreme chemical inertness and a soft, conformable structure. This allows it to create a reliable seal on irregular surfaces where traditional, pre-cut gaskets would fail.

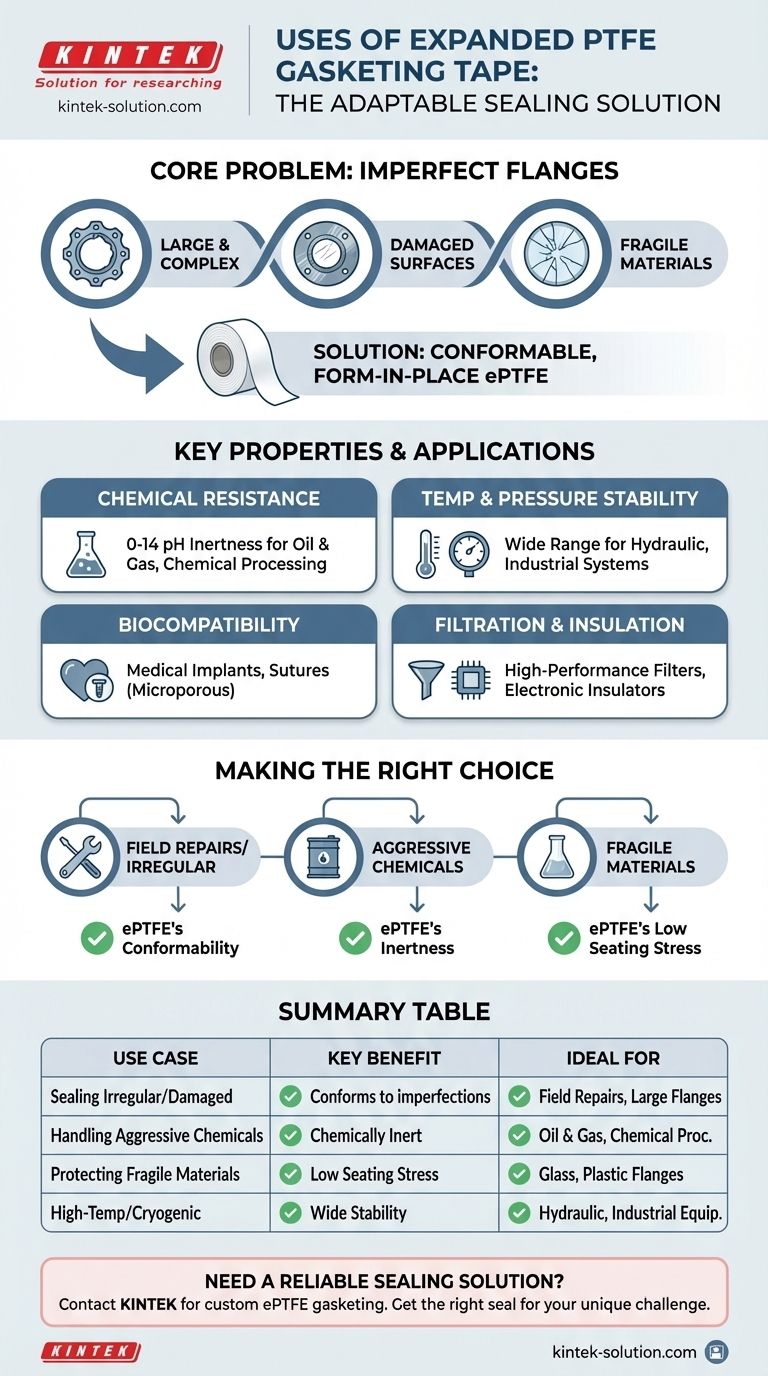

The Core Problem ePTFE Tape Solves: The Imperfect Flange

Standard gaskets require clean, flat, and perfectly aligned flange surfaces to function correctly. Expanded PTFE tape is engineered for the real world, where conditions are often less than ideal.

Sealing Large and Complex Flanges

A single spool of ePTFE tape can be used to form a custom gasket for nearly any size or shape. This eliminates the need to stock numerous, expensive, large-diameter pre-cut gaskets, simplifying inventory and reducing costs.

Compensating for Damaged Surfaces

The soft, marshmallow-like consistency of ePTFE is its greatest asset. It easily compresses into scratches, pits, and minor warping on a flange face, filling imperfections to create a tight, dependable seal with relatively low bolt torque.

Protecting Fragile Materials

Many sealing materials require significant compressive force to work, which can easily crack or damage flanges made of glass, plastic, or ceramic. Because ePTFE is so conformable, it achieves a reliable seal with minimal clamping force, protecting these sensitive components.

Key Properties Driving Widespread Use

The applications for ePTFE extend far beyond simple flange sealing due to the material's inherent properties. It's not just a gasket tape; it's a high-performance material used in advanced fields.

Extreme Chemical Resistance

Expanded PTFE is chemically inert across the entire 0-14 pH range. This makes it a default choice for sealing flanges in pipelines, pumps, and pressure vessels that handle aggressive chemicals, solvents, and acids, particularly in the oil and gas industries.

Wide Temperature and Pressure Stability

This material remains effective in a vast range of environments, from cryogenic applications to high-temperature systems. It is commonly used to seal flange joints in hydraulic and pneumatic systems, fire hydrants, and other demanding industrial equipment.

Biocompatibility and Microporous Structure

A unique property of ePTFE is its microporous structure, which allows human tissue to grow into it. This biocompatibility makes it a critical material for medical implants like artificial blood vessels, surgical sutures, and heart patches.

Filtration and Insulation

The same microporous structure that aids in medical applications also makes ePTFE a high-performance filter material for environmental and fluid purification systems. Furthermore, its excellent dielectric properties make it a valuable electronic insulator in semiconductor and scientific equipment.

Understanding the Trade-offs

While incredibly versatile, ePTFE is not a universal solution. Understanding its limitations is key to using it effectively.

Creep and Cold Flow

Like all PTFE materials, ePTFE can be subject to "creep" or "cold flow," where the material slowly deforms under constant pressure. This may require re-torquing bolts after installation to maintain seal integrity, especially in applications with thermal cycling.

Monodirectional vs. Multidirectional

ePTFE tape comes in two main forms. Monodirectional is strong along its length but can spread under pressure. Multidirectional ePTFE is processed to have uniform strength in all directions, making it more resistant to creep and better suited for very large, complex, or thermally dynamic flanges.

Not for Extreme Pressures

While robust, ePTFE is a soft material. In extremely high-pressure systems, a more rigid solution like a spiral-wound or solid metal gasket may be necessary to prevent the gasket from being forced out of the joint.

Making the Right Choice for Your Goal

To select the right sealing solution, match the material's strengths to your primary challenge.

- If your primary focus is quick field repairs or sealing irregular flanges: ePTFE tape is the ideal choice due to its form-in-place nature and ability to conform to surface imperfections.

- If your primary focus is sealing aggressive chemicals or wide temperature ranges: The unmatched chemical inertness and thermal stability of ePTFE make it a safe and reliable option.

- If your primary focus is sealing fragile materials like glass or plastic: The low required seating stress of ePTFE prevents damage to brittle flange materials where other gaskets would fail.

Ultimately, expanded PTFE gasketing tape provides a powerful, adaptable sealing solution that solves problems traditional pre-cut gaskets simply cannot.

Summary Table:

| Use Case | Key Benefit | Ideal For |

|---|---|---|

| Sealing Irregular/Damaged Flanges | Conforms to scratches & pits | Field repairs, large complex flanges |

| Handling Aggressive Chemicals | Chemically inert (0-14 pH) | Oil & gas, chemical processing |

| Protecting Fragile Materials | Low seating stress | Glass, plastic, ceramic flanges |

| High-Temperature/Cryogenic Sealing | Wide temperature stability | Hydraulic systems, industrial equipment |

Need a reliable sealing solution for your specific application?

KINTEK specializes in manufacturing high-performance PTFE components, including custom ePTFE gasketing solutions. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering precision and reliability from prototype to high-volume production.

Our expertise ensures you get the right seal for your unique challenges, whether it's chemical resistance, temperature stability, or protecting delicate materials. Let us help you solve your toughest sealing problems.

Contact KINTEK today for a custom solution and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the advantages of PTFE slide bearings over conventional supports? Achieve Frictionless Movement for Durable Structures

- What challenges do manufacturers face when designing PTFE sliding bearings? Navigating Custom Engineering for Structural Safety

- What are the main strengths of virgin PTFE? Achieve Unmatched Chemical Purity and Thermal Stability

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges

- What are some industrial and niche applications of PTFE coatings? Solve Your Toughest Corrosion and Friction Problems

- Why do PTFE gaskets have a long service life? Achieve Unmatched Sealing Durability & Cost Savings

- What industries commonly use PTFE rotary shaft seals? The Ultimate Guide for Extreme Conditions

- What material properties make polymer-plastic ball bearings suitable for diverse industries? Solve Harsh Environment Challenges