PTFE gaskets achieve their long service life due to an exceptional combination of inherent material properties. Their molecular structure makes them nearly immune to chemical corrosion and capable of withstanding extreme temperatures, all while maintaining the physical flexibility needed for a durable, long-lasting seal.

The core reason for PTFE's longevity is its fundamental stability. Its resistance to chemical attack, thermal degradation, and mechanical wear directly reduces the frequency of repairs and replacements, lowering long-term maintenance costs.

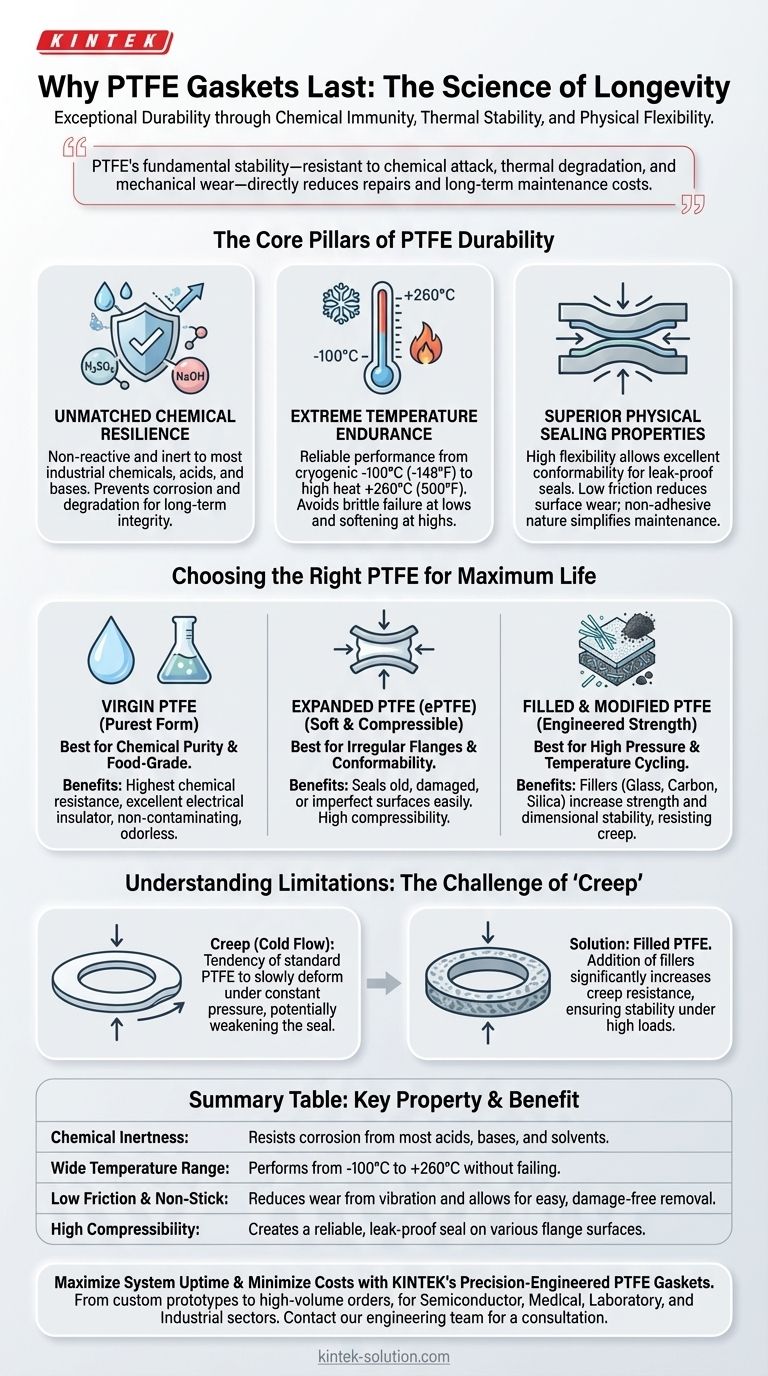

The Core Pillars of PTFE Durability

The remarkable service life of Polytetrafluoroethylene (PTFE) gaskets stems from three primary characteristics. Understanding these pillars is key to appreciating why this material is trusted in so many demanding industries.

Unmatched Chemical Resilience

PTFE is one of the most chemically inert materials known. It is non-reactive and will not corrode or degrade when exposed to the vast majority of industrial chemicals, acids, and bases.

This property ensures the gasket's integrity is not compromised by the media it is sealing, preventing leaks and contamination over long periods.

Extreme Temperature Endurance

PTFE gaskets perform reliably across an exceptionally wide temperature range, typically from cryogenic lows of -100°C (-148°F) up to high temperatures of +260°C (500°F).

This thermal stability means the gasket material won't become brittle at low temperatures or soften and fail in high-heat applications, a common failure point for other materials.

Superior Physical Sealing Properties

Beyond its resistance, PTFE’s physical nature is ideal for sealing. Its flexibility allows it to compress easily, conforming to flange surfaces to create a tight, leak-proof seal.

Furthermore, PTFE has an extremely low coefficient of friction, which reduces surface wear during thermal expansion, contraction, or vibration. Its non-adhesive surface also simplifies removal and cleaning, preventing damage to equipment.

Why Not All PTFE Gaskets Are Equal

While all PTFE shares these core benefits, specialized variations have been developed to enhance performance for specific applications. Choosing the correct type is crucial for maximizing service life.

Virgin PTFE

This is the purest form of PTFE, containing no fillers. It offers the highest chemical resistance and is an excellent electrical insulator.

Its non-contaminating, odorless nature makes it the standard choice for food, pharmaceutical, and ultra-pure chemical applications.

Expanded PTFE (ePTFE)

ePTFE is a modified form of PTFE that is much softer and more compressible than its virgin counterpart.

This makes it exceptionally good at sealing old, damaged, or irregular flange surfaces that a harder gasket might struggle with.

Filled & Modified PTFE

Fillers such as glass, carbon, or silica are added to virgin PTFE to enhance specific mechanical properties.

These fillers are not for cost reduction; they are engineered to improve the gasket's strength and stability under demanding conditions.

Understanding the Trade-offs and Limitations

True expertise comes from understanding not just a material's strengths, but also its potential weaknesses. For PTFE, the primary consideration is its behavior under mechanical load.

The Challenge of "Creep"

Standard, or virgin, PTFE can be susceptible to creep, also known as cold flow. This is the tendency for the material to slowly deform over time when under constant pressure.

In some high-pressure applications, creep can eventually lead to a loss of bolt torque and a weakened seal.

How Fillers Provide a Solution

This is precisely why filled PTFE gaskets were developed. The addition of filler materials significantly increases the gasket's resistance to creep.

A glass-filled or carbon-filled PTFE gasket will be far more dimensionally stable under high mechanical loads and temperature cycling, ensuring a more reliable long-term seal in those conditions.

Making the Right Choice for Your System

Selecting the correct gasket variant is the key to unlocking its maximum service life and ensuring system reliability.

- If your primary focus is chemical purity or food-grade applications: Virgin PTFE is the ideal choice due to its inert, non-contaminating properties.

- If your primary focus is managing high pressure or temperature cycling: A filled PTFE gasket offers superior resistance to creep and mechanical deformation.

- If your primary focus is sealing an irregular or imperfect flange surface: Expanded PTFE (ePTFE) provides the necessary softness and compressibility for a tight seal.

By aligning the material's specific strengths with your operational demands, you can confidently specify a PTFE gasket engineered to last.

Summary Table:

| Key Property | Benefit for Service Life |

|---|---|

| Chemical Inertness | Resists corrosion from most acids, bases, and solvents. |

| Wide Temperature Range | Performs from -100°C to +260°C without failing. |

| Low Friction & Non-Stick | Reduces wear from vibration and allows for easy, damage-free removal. |

| High Compressibility | Creates a reliable, leak-proof seal on various flange surfaces. |

Maximize your system's uptime and minimize maintenance costs with precision-engineered PTFE gaskets from KINTEK.

Whether your application demands the ultimate chemical purity of Virgin PTFE for semiconductor or pharmaceutical use, the superior creep resistance of Filled PTFE for high-pressure industrial systems, or the excellent conformability of Expanded PTFE (ePTFE) for challenging surfaces, KINTEK has the solution.

We specialize in custom fabricating high-performance PTFE components—from prototypes to high-volume orders—for the semiconductor, medical, laboratory, and industrial sectors. Let our expertise ensure you get the perfect, long-lasting seal for your specific operational demands.

Contact our engineering team today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance