From deep-sea drilling rigs to sterile medical labs, PTFE rotary shaft seals are the go-to solution in a wide array of demanding industries. Their unique properties make them indispensable in sectors like automotive, aerospace, oil and gas, chemical processing, and food and pharmaceutical manufacturing, where standard seals would quickly fail.

The specific industry is less important than the operational challenge. PTFE seals are chosen not for the sector, but for the extreme conditions common within them—high speeds, corrosive chemicals, and severe temperatures where traditional elastomer seals are inadequate.

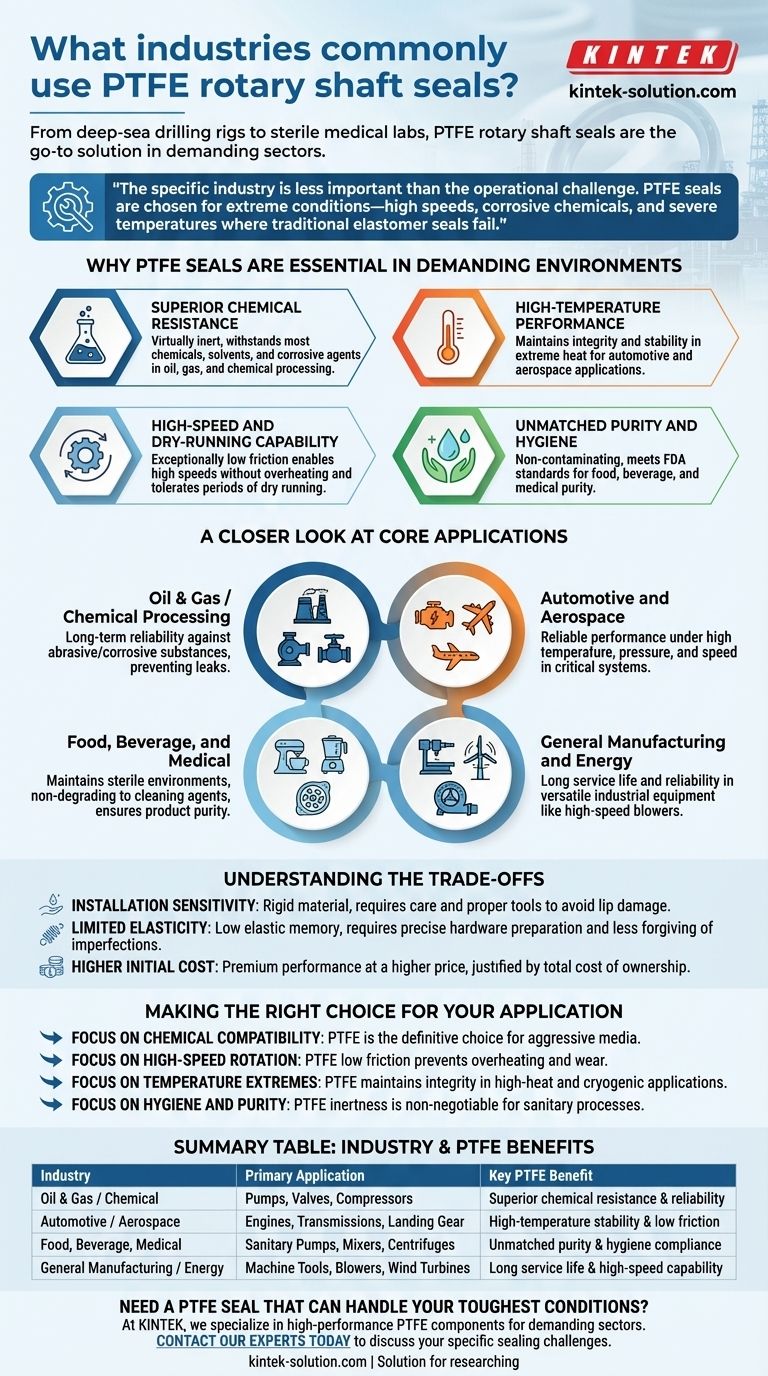

Why PTFE Seals are Essential in Demanding Environments

The widespread adoption of Polytetrafluoroethylene (PTFE) seals is a direct result of the material's superior performance characteristics. Engineers turn to PTFE when the operational environment is simply too harsh for conventional rubber or elastomer seals.

Superior Chemical Resistance

PTFE is virtually inert, meaning it does not react with most industrial chemicals, solvents, and corrosive agents. This makes it the default choice in chemical processing plants, oil and gas equipment, and pharmaceutical mixers where seals are constantly exposed to aggressive media.

High-Temperature Performance

Standard rubber seals can degrade, harden, or lose their sealing ability at high temperatures. PTFE, however, maintains its integrity and stability in extreme heat, making it crucial for applications like automotive engines, transmissions, and aircraft components.

High-Speed and Dry-Running Capability

The exceptionally low friction coefficient of PTFE is a key advantage. This allows PTFE seals to operate at much higher rotational speeds without generating destructive heat, a common failure point for elastomer seals. They can even tolerate periods of dry running, a condition that would destroy a standard seal almost instantly.

Unmatched Purity and Hygiene

In the food, beverage, and medical industries, preventing contamination is the primary goal. PTFE is a non-contaminating material and can be manufactured to meet stringent FDA and other sanitary standards, ensuring product purity in mixers, pumps, and processing equipment.

A Closer Look at Core Applications

While the principles apply broadly, seeing how different industries leverage these benefits provides a clearer picture of their value.

Oil & Gas and Chemical Processing

In this sector, equipment like pumps, valves, and compressors handle abrasive and corrosive substances under immense pressure. PTFE seals provide the long-term reliability needed to prevent costly and hazardous leaks, extending equipment life and reducing maintenance.

Automotive and Aerospace

From high-RPM engine crankshafts to aircraft landing gear, components are subjected to high temperatures, pressures, and speeds. PTFE seals ensure reliable performance and longevity in these critical systems where failure could be catastrophic.

Food, Beverage, and Medical

Here, the challenge is maintaining a sterile environment. PTFE seals are used in sanitary pumps, mixers, and centrifuges because they won't degrade when exposed to cleaning agents and won't impart any taste, color, or contaminants into the product.

General Manufacturing and Energy

The versatility of PTFE extends to a wide range of industrial equipment. This includes machine tools, high-speed blowers, screw compressors, and even renewable energy applications like wind turbines, where long service intervals and reliability are paramount.

Understanding the Trade-offs

Despite their advantages, PTFE seals are not a universal solution. Understanding their limitations is key to using them effectively.

Installation Sensitivity

PTFE is a rigid plastic, not a flexible rubber. The seal lip is more susceptible to damage during installation if not handled with care. Proper tools and procedures are required to avoid nicks or scratches that could create a leak path.

Limited Elasticity

Unlike elastomers, PTFE has very little "elastic memory." This means it is less forgiving of imperfections in the shaft or housing, such as significant runout or rough surface finishes. The hardware preparation must be more precise for a PTFE seal to function correctly.

Higher Initial Cost

Premium performance comes at a higher price. PTFE seals are typically more expensive than their standard elastomeric counterparts. The decision to use them is a calculation based on total cost of ownership, where their longer life and reduced downtime justify the upfront investment.

Making the Right Choice for Your Application

Selecting a seal requires matching the material's strengths to your primary operational challenge.

- If your primary focus is chemical compatibility: PTFE is the definitive choice for sealing against aggressive or corrosive media where elastomers would dissolve or degrade.

- If your primary focus is high-speed rotation: The low-friction properties of PTFE are essential to prevent overheating and premature wear in high-RPM equipment.

- If your primary focus is temperature extremes: PTFE seals maintain their integrity and sealing force in both high-heat and cryogenic applications that fall far outside the range of rubber.

- If your primary focus is hygiene and purity: PTFE's inertness and compliance with food-grade standards make it non-negotiable for sanitary processes.

Ultimately, a PTFE seal is chosen when operational demands exceed the capabilities of conventional materials, ensuring reliability where failure is not an option.

Summary Table:

| Industry | Primary Application | Key PTFE Benefit |

|---|---|---|

| Oil & Gas / Chemical | Pumps, Valves, Compressors | Superior chemical resistance & reliability |

| Automotive / Aerospace | Engines, Transmissions, Landing Gear | High-temperature stability & low friction |

| Food, Beverage, Medical | Sanitary Pumps, Mixers, Centrifuges | Unmatched purity & hygiene compliance |

| General Manufacturing / Energy | Machine Tools, Blowers, Wind Turbines | Long service life & high-speed capability |

Need a PTFE Seal That Can Handle Your Toughest Conditions?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and custom labware—for the most demanding environments in the semiconductor, medical, laboratory, and industrial sectors. Our focus on precision production ensures reliability where failure is not an option, whether you need a custom prototype or a high-volume order.

Contact our experts today to discuss how our PTFE solutions can solve your specific sealing challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry