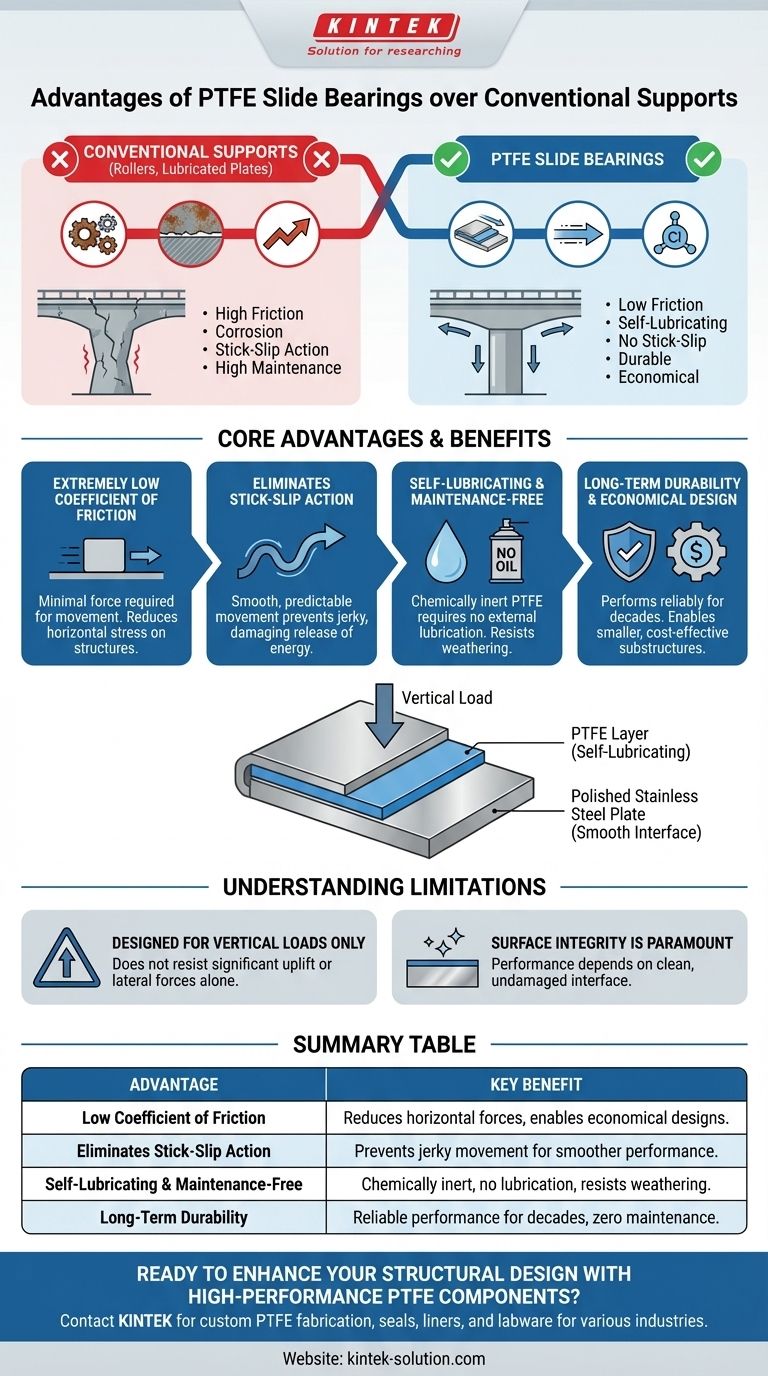

The primary advantages of PTFE slide bearings are their extremely low coefficient of friction, inherent self-lubricating properties, and complete resistance to stick-slip action. By allowing controlled, smooth movement, they significantly reduce the horizontal forces transferred to a structure's supports, leading to more economical and durable designs compared to conventional methods like rollers or expansion plates.

The core function of a PTFE slide bearing is not just to support a load, but to decouple a structure from the harmful stresses caused by movement. This elegant separation of duties—vertical support from horizontal motion—is what makes them superior for modern infrastructure.

The Core Problem: Managing Structural Movement

All large structures move. Forces from thermal expansion and contraction, seismic activity, or differential loads cause components to shift relative to one another. A support system must safely accommodate this movement without compromising the integrity of the structure.

The Failure of Conventional Supports

Older methods like lubricated plates, rollers, or rocker arms attempt to solve this problem but have inherent flaws. They often suffer from high friction, corrosion, and "stick-slip" action—a jerky, uncontrolled release of built-up stress that can damage both the structure and its supports.

The Goal of an Ideal Bearing

An ideal structural bearing should carry the required vertical load while offering minimal resistance to horizontal movement. It must be durable, require little to no maintenance, and perform reliably for decades in demanding environmental conditions.

How PTFE Bearings Revolutionize Load Management

PTFE slide bearings achieve the ideal by using the unique properties of Polytetrafluoroethylene (PTFE), the same material known commercially as Teflon. A thin layer of PTFE slides against a polished stainless steel plate, creating a near-perfect sliding interface.

Achieving Near-Frictionless Movement

The defining feature of PTFE is its incredibly low coefficient of friction. This means very little energy is required to initiate or sustain movement.

This directly translates into smaller horizontal forces being transferred to piers, columns, and foundations, which is a massive advantage for the overall structural design.

Eliminating Stick-Slip Action

Unlike simple lubricated plates that can bind and release, PTFE bearings move smoothly and consistently. The elimination of stick-slip action prevents the sudden, jarring release of energy that can induce fatigue and stress into structural members over time.

Simplifying Design and Reducing Costs

By dramatically reducing the frictional forces the supporting structure must withstand, engineers can design more economical substructures. Piers and foundations can be made smaller and require less reinforcement, leading to significant savings in materials and construction costs.

Ensuring Long-Term Durability

PTFE is chemically inert and unaffected by weathering, moisture, or industrial pollutants. This anti-weathering and chemical resistance means the bearings do not corrode or degrade, offering a long service life with virtually zero maintenance.

Understanding the Trade-offs and Limitations

While highly effective, PTFE slide bearings are specialized components designed for a specific purpose. Understanding their limitations is crucial for proper application.

Designed for Vertical Loads Only

A standard PTFE slide bearing is engineered to support vertical (compressive) loads while allowing horizontal translation. It is not designed to resist uplift, moment, or significant lateral forces on its own. Additional restraints or guides must be incorporated into the design if those forces need to be managed.

Surface Integrity is Paramount

The bearing's performance depends entirely on the smooth, clean interface between the PTFE and the polished stainless steel plate. Any significant damage, scoring, or contamination of the stainless steel surface can compromise the bearing's low-friction properties and overall effectiveness.

Making the Right Choice for Your Project

Selecting PTFE bearings over conventional supports depends on your project's primary engineering goals.

- If your primary focus is cost efficiency: PTFE bearings enable more economical designs for the supporting substructure by minimizing the horizontal forces it must resist.

- If your primary focus is longevity and low maintenance: The chemical and weather resistance of PTFE makes it the ideal choice for structures in harsh environments, such as petrochemical plants or coastal bridges.

- If your primary focus is managing high movement: For structures with significant thermal expansion (pipelines, long-span bridges) or seismic requirements, the frictionless, stick-slip-free movement is a critical safety and performance feature.

Ultimately, PTFE slide bearings provide a more advanced and efficient solution for managing the inevitable forces that act on modern structures.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Low Coefficient of Friction | Reduces horizontal forces on supports, enabling more economical designs. |

| Eliminates Stick-Slip Action | Prevents jerky, damaging movement for smoother, more predictable performance. |

| Self-Lubricating & Maintenance-Free | Chemically inert PTFE requires no lubrication and resists weathering. |

| Long-Term Durability | Performs reliably for decades in harsh environments with zero maintenance. |

Ready to enhance your structural design with high-performance PTFE components?

At KINTEK, we specialize in the precision manufacturing of custom PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your project benefits from the superior material properties of PTFE, leading to more durable, efficient, and cost-effective solutions.

Contact us today to discuss your specific requirements for custom PTFE fabrication, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs