The primary challenges in designing PTFE sliding bearings stem from their role as custom solutions for unique, high-stakes structural applications. Manufacturers must navigate late-stage design changes, severe physical site constraints, and the complex material science required to ensure the bearing performs reliably under specified loads and movements without failure.

The core challenge is not simply manufacturing a part, but engineering a bespoke component that solves a specific structural problem. This requires translating last-minute project requirements and tight physical constraints into a high-performance bearing where the bonding of the PTFE liner is the most critical point of failure.

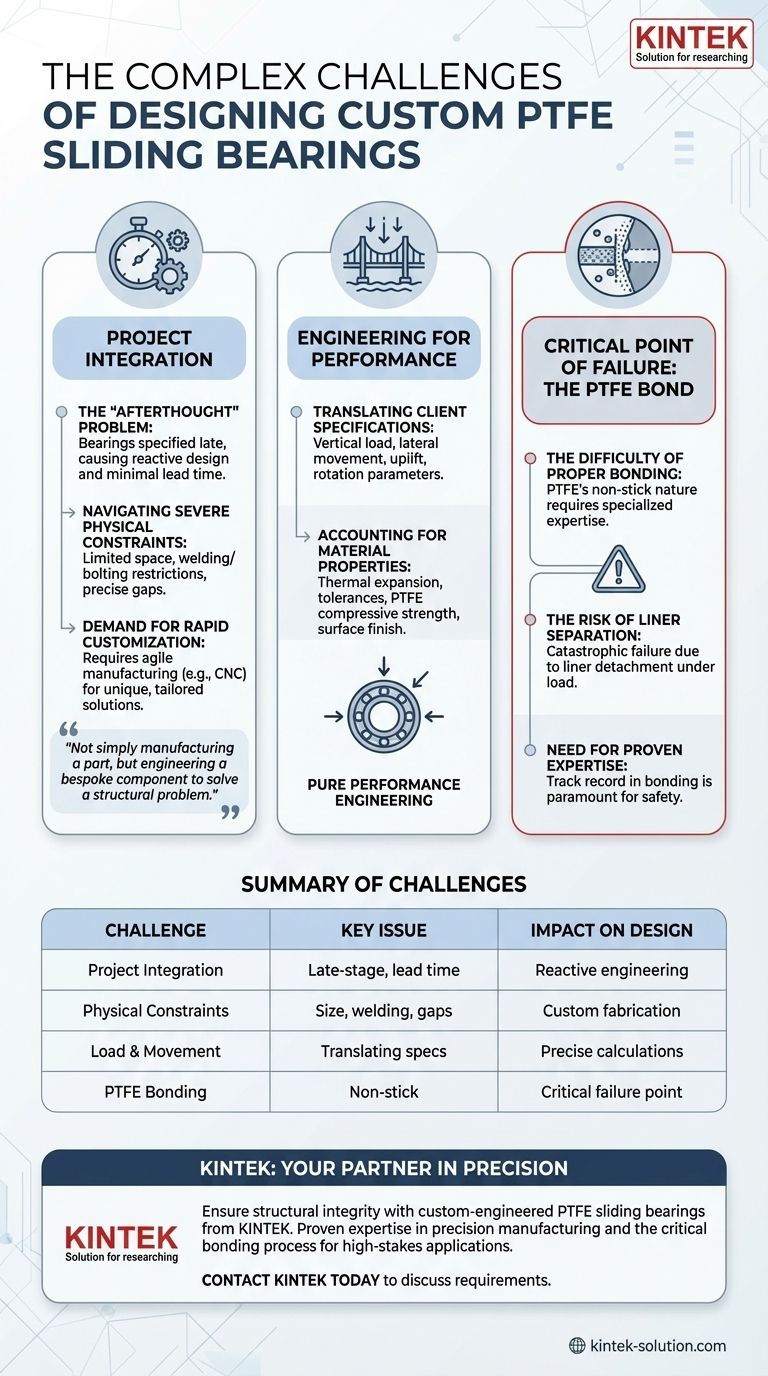

The Challenge of Project Integration

PTFE sliding bearings are rarely off-the-shelf products. They are custom-fabricated components that must fit perfectly within a larger structural design, often under difficult circumstances.

The "Afterthought" Problem

In many construction and infrastructure projects, bearings are one of the last components to be specified. This leaves manufacturers with minimal lead time to address complex engineering problems.

This late-stage integration forces a reactive design process, increasing pressure and the potential for error.

Navigating Severe Physical Constraints

Manufacturers are frequently constrained by the existing site conditions. This includes limits on the size of the portal plate the bearing will sit on or restrictions on welding or bolting to the primary structure.

They must also design for the precise gaps between the substructure and superstructure, which can vary significantly from the original blueprints.

The Demand for Rapid Customization

The combination of late-stage requirements and physical constraints means nearly every PTFE bearing is a custom job. This necessitates agile manufacturing processes, like CNC machining, that can adapt to unique variables for precise fabrication.

This tailored approach makes these bearings premium products, as each must be engineered specifically for its intended location and purpose.

Engineering for Specific Loads and Movements

Beyond the physical fit, the bearing must be designed to handle the exact forces it will experience over its lifespan. This is a matter of pure performance engineering.

Translating Client Specifications

The process begins with client-provided parameters. These include the expected vertical load, longitudinal and lateral movement, potential uplift loads, and required rotation.

The manufacturer's engineering team must then design the bearing's composition—the steel plates, the PTFE layer, and the stainless steel sliding surface—to safely accommodate these forces.

Accounting for Material Properties

The design must consider the operational environment. Factors like thermal expansion, material tolerances, and the compressive strength of the PTFE are critical.

The surface finish of the polished stainless-steel plate is also crucial, as it directly impacts the coefficient of friction and the bearing's long-term performance.

Understanding the Critical Point of Failure: The PTFE Bond

While design parameters are complex, the most common and catastrophic failure point in a PTFE bearing is more fundamental: the bond holding the PTFE liner to the steel plate.

The Difficulty of Proper Bonding

PTFE is known for its non-stick properties, which makes it incredibly difficult to bond securely to another surface. This process is a specialized skill that requires extensive experience and knowledge.

An improper bond is a hidden defect that can have severe consequences once the bearing is installed and under load.

The Risk of Liner Separation

If the bond fails, the PTFE liner can separate from the backing plate. This leads to rapid degradation of the bearing's sliding capability and can cause a sudden, catastrophic failure of the entire component.

The Need for Proven Expertise

Because of this risk, selecting a manufacturer is less about cost and more about their proven track record. True expertise in the bonding process is the most important factor in ensuring the bearing's long-term safety and reliability.

Making the Right Choice for Your Project

To mitigate these manufacturing challenges from a client's perspective, your approach should align with your project's primary goals.

- If your primary focus is the project timeline: Engage bearing manufacturers early in the design process to provide them with ample time for proper engineering, avoiding the delays caused by last-minute customization.

- If your primary focus is structural integrity and reliability: Scrutinize the manufacturer's experience specifically with the PTFE bonding process, as this is the single most critical factor in preventing catastrophic failure.

- If your primary focus is navigating complex site constraints: Provide the manufacturer with detailed, accurate site specifications as early as possible to allow for precise fabrication of a custom-fit solution.

Ultimately, treating PTFE sliding bearings as critical, custom-engineered components from the outset is the key to ensuring structural safety and project success.

Summary Table:

| Challenge | Key Issue | Impact on Design |

|---|---|---|

| Project Integration | Late-stage design changes, minimal lead time | Forces reactive engineering, increases error risk |

| Physical Constraints | Size limits, welding/bolting restrictions, gap variations | Demands precise, custom fabrication for each site |

| Load & Movement Engineering | Translating vertical load, lateral movement, rotation specs | Requires precise material selection and structural calculation |

| PTFE Bonding | PTFE's non-stick properties make secure adhesion difficult | The most critical point of failure; requires specialized expertise |

Ensure the structural integrity of your project with custom-engineered PTFE sliding bearings from KINTEK.

Navigating the complexities of PTFE bearing design requires a partner with proven expertise in precision manufacturing and, most critically, the specialized bonding process. KINTEK manufactures high-performance PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your bearing is engineered to handle specific loads, movements, and site constraints without failure.

Don't leave your project's safety to chance. Contact KINTEK today to discuss your custom PTFE sliding bearing requirements and leverage our expertise for a reliable, high-stakes solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs