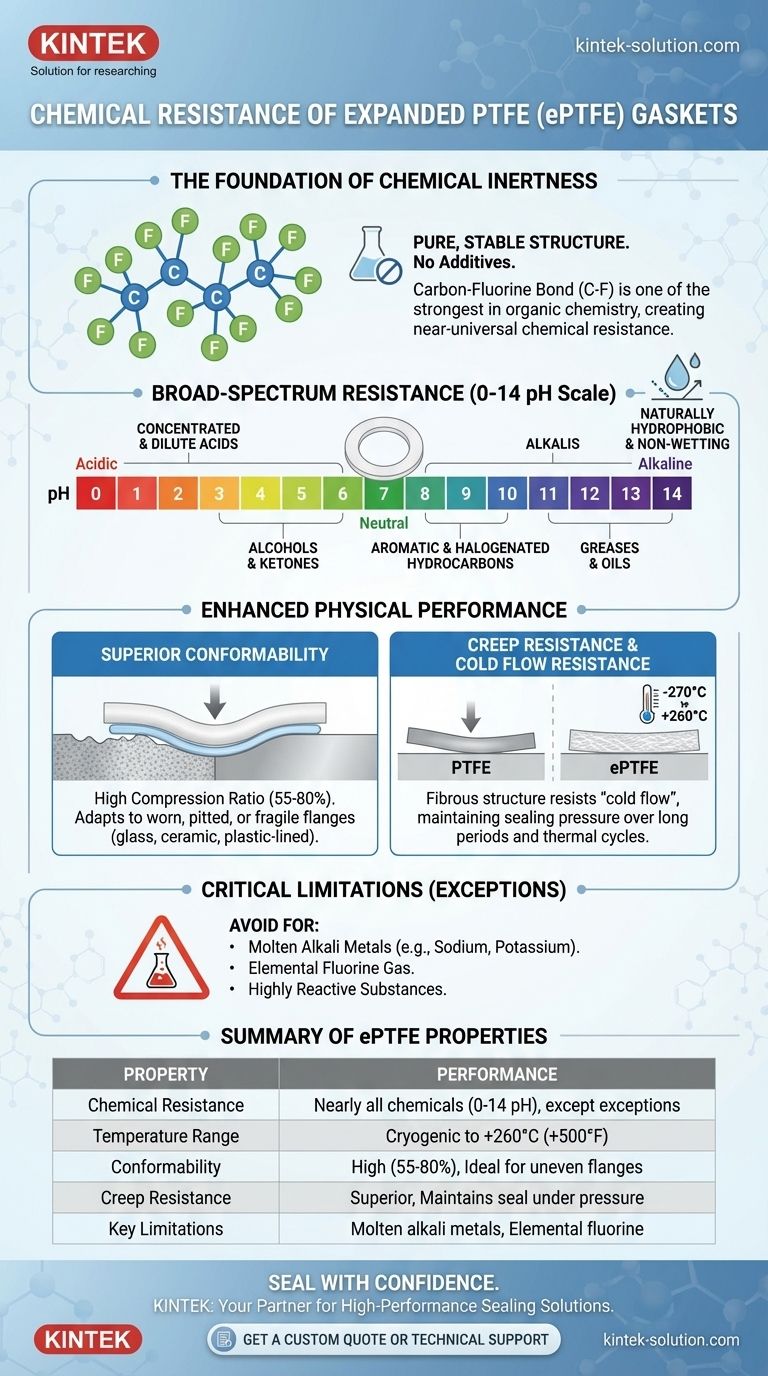

To put it simply, an expanded PTFE (ePTFE) gasket is chemically resistant to nearly every substance across the entire 0-14 pH scale. Its chemical inertness is one of the most comprehensive of any sealing material available. The only common exceptions are highly reactive substances like molten alkali metals and elemental fluorine.

The core reason for expanded PTFE's exceptional chemical resistance is its pure, stable molecular structure. Composed solely of carbon and fluorine, it lacks additives that could leach or react, making it a default choice for aggressive chemical services and high-purity applications.

The Foundation of ePTFE's Chemical Inertness

The remarkable resistance of expanded PTFE is not an accident of manufacturing; it is a direct result of its fundamental chemistry and processing.

The Power of the Carbon-Fluorine Bond

Expanded PTFE is a synthetic fluoropolymer made of tetrafluoroethylene. Its molecular structure consists of a strong carbon backbone completely shielded by a dense layer of fluorine atoms.

This carbon-fluorine bond is one of the strongest in organic chemistry, rendering the material almost universally inert and non-reactive.

A Pure, Additive-Free Material

Expanded PTFE is created by physically expanding virgin PTFE, introducing a porous, fibrous structure without the need for chemical additives.

This means it possesses the same outstanding chemical resistance as virgin PTFE. There are no plasticizers, fillers, or bonding agents that could compromise its integrity or contaminate the process media.

Broad-Spectrum Resistance

This inherent stability makes ePTFE gaskets unaffected by the vast majority of corrosive liquids, vapors, and gases.

This includes excellent resistance to:

- Concentrated and dilute acids

- Alkalis

- Alcohols and ketones

- Aromatic and halogenated hydrocarbons

- Greases and oils

Because it is made of pure carbon and fluorine, the material is also naturally hydrophobic (water-repelling), non-wetting, and non-contaminating.

How Physical Properties Enhance Sealing Performance

While chemical inertness is critical, a gasket's physical properties determine its real-world effectiveness. The unique structure of ePTFE provides mechanical advantages that complement its chemical resistance.

Superior Conformability

Expanded PTFE is exceptionally soft and flexible, with a typical compression ratio between 55% and 80%.

This allows it to conform easily to surface irregularities, creating a tight seal even on worn, pitted, or fragile flanges like glass, ceramic, or plastic-lined equipment.

Resistance to Creep and Cold Flow

A significant advantage of ePTFE over standard PTFE is its resistance to creep (the tendency of a material to deform under sustained pressure).

The fibrous, multi-directional structure of ePTFE resists the "cold flow" common in solid PTFE, ensuring the gasket maintains its sealing pressure over long periods and through thermal cycles.

Wide Operational Temperature Range

Expanded PTFE maintains its properties across an extremely broad temperature spectrum, from cryogenic conditions up to approximately +260°C (+500°F).

This allows it to be specified in applications involving extreme temperature swings without compromising the seal's chemical resistance or physical integrity.

Understanding the Critical Limitations

No material is perfect for every situation. Being aware of ePTFE's specific limitations is key to using it effectively and safely.

The Few Chemical Exceptions

The material's only significant chemical vulnerabilities are to the most aggressive and reactive substances known.

Molten alkali metals (like sodium or potassium) and powerful fluorinating agents like elemental fluorine gas are reactive enough to attack the carbon-fluorine bond itself. For nearly all other industrial applications, this is not a concern.

Mechanical Considerations

While tough, ePTFE is a soft material. In extremely high-pressure systems that might cause extrusion, or where gasket rotation and massive bolt loads are required, a metallic or semi-metallic gasket might be more appropriate.

Its elastic recovery of 15-20% is lower than rubber elastomers, meaning it relies more on its initial conformability than on "spring-back" to maintain a seal.

Making the Right Choice for Your Application

Choosing a gasket requires matching the material's properties to the system's demands. Expanded PTFE is a premier problem-solver in several key areas.

- If your primary focus is aggressive chemical sealing: ePTFE is one of the safest and most reliable choices due to its near-universal chemical inertness and resistance to creep.

- If your primary focus is protecting fragile or uneven flanges: The exceptional softness and conformability of ePTFE create a tight seal with low bolt torque, preventing damage to sensitive equipment.

- If your primary focus is process purity: In food, pharmaceutical, or semiconductor applications, ePTFE's FDA compliance and non-contaminating, additive-free nature make it an ideal selection.

By understanding both its unmatched chemical resistance and its unique physical strengths, you can confidently specify expanded PTFE for your most demanding sealing challenges.

Summary Table:

| Property | ePTFE Gasket Performance |

|---|---|

| Chemical Resistance | Resistant to nearly all chemicals (acids, alkalis, solvents) across 0-14 pH scale |

| Temperature Range | Cryogenic to +260°C (+500°F) |

| Conformability | High (55-80% compression ratio), ideal for fragile or uneven flanges |

| Creep Resistance | Superior to standard PTFE, maintains seal under sustained pressure |

| Key Limitations | Not suitable for molten alkali metals or elemental fluorine |

Seal with confidence for your most demanding applications.

At KINTEK, we manufacture high-performance expanded PTFE components—including seals, gaskets, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, ensure you get a sealing solution perfectly matched to your chemical and physical requirements.

Contact us today to discuss how our ePTFE gaskets can solve your sealing challenges and protect your critical processes.

Get a Custom Quote or Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Which acids show high resistance with Teflon FEP and PFA encapsulated O-rings? Ensure Leak-Free Performance in Aggressive Chemical Environments

- What types of PTFE shapes are available? From Stock Forms to Custom Components

- How should one choose between virgin and glass-filled Teflon balls? A Guide to Material Selection

- How can the creep formation issue in PTFE gaskets be addressed? Ensure a Long-Term, Leak-Free Seal

- What role do PTFE coatings play in automotive engineering? Boost Engine Efficiency & Durability

- What are the key properties of PTFE material used in the spacer? Ensure Stability in Harsh Environments

- How do expanded PTFE gaskets handle surface irregularities? Achieve a Perfect Seal on Imperfect Flanges

- What are spring-energized seals, and why are they used in extreme environments?