To address creep formation in PTFE gaskets, the definitive solution is to select materials specifically engineered for creep resistance, such as reinforced or modified PTFE formulations. These advanced gaskets incorporate fillers or structural changes that physically inhibit the material's tendency to deform under load, ensuring a more stable and reliable long-term seal.

The core problem is not an inherent flaw in PTFE, but the misapplication of pure, unmodified PTFE in conditions where it is susceptible to "creep" or "cold flow." The solution is to specify a filled or restructured PTFE gasket that is mechanically stable at your system's specific operating temperature and pressure.

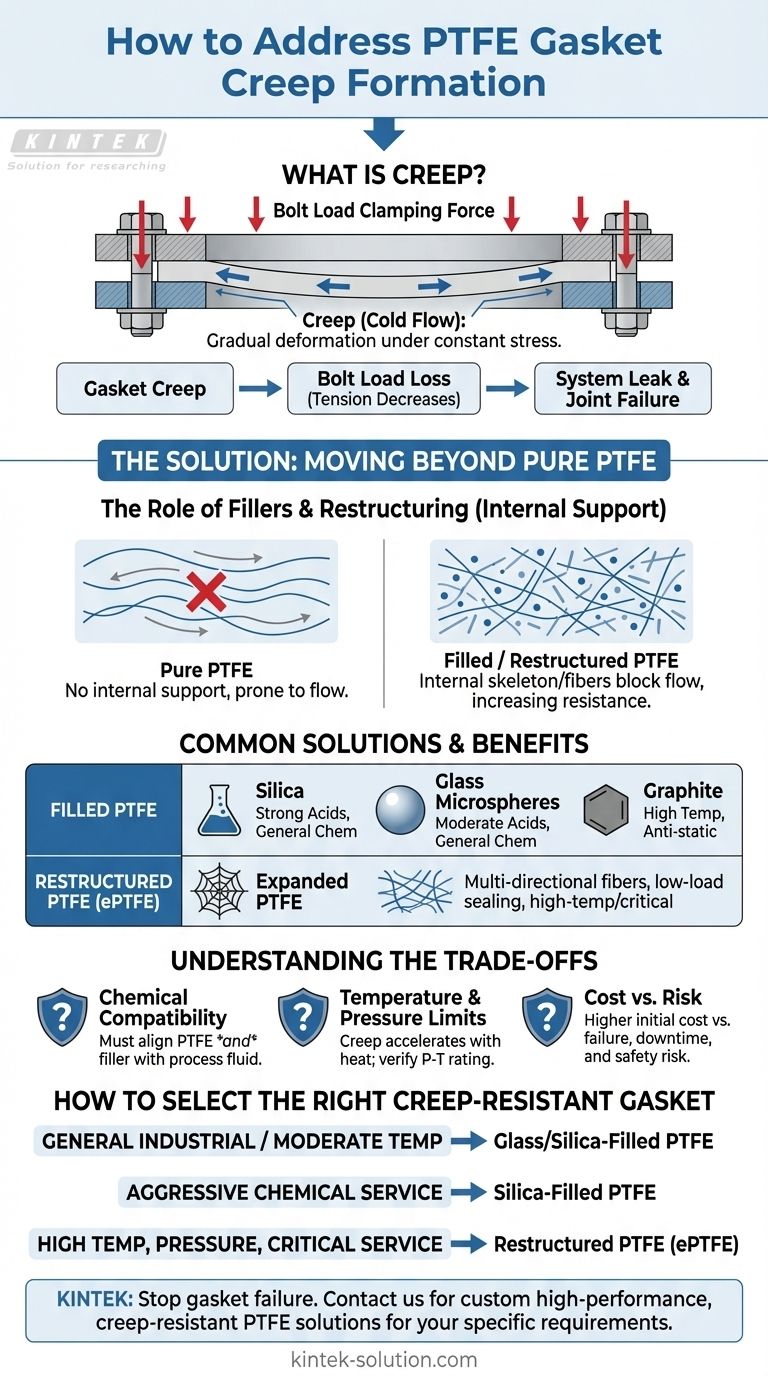

What is Creep and Why Does it Matter?

Before solving the problem, it's critical to understand the mechanism of failure. Pure PTFE, for all its chemical inertness and low friction, has a significant weakness in mechanical applications.

Understanding "Creep" or "Cold Flow"

Creep is the tendency of a solid material to deform slowly and permanently under the influence of a constant mechanical stress. In gaskets, this stress is the clamping force from the flange bolts.

Imagine the gasket as a very dense, slow-moving fluid. The bolt load constantly squeezes it, and over time, the material "flows" outward, away from the pressure.

The Consequence: Loss of Bolt Load

As the gasket material creeps and becomes thinner, the tension in the flange bolts decreases. This is known as loss of bolt torque or loss of bolt load.

The initial clamping force you carefully applied during installation is no longer being maintained because the gasket it was pressing against has effectively shrunk.

The Result: System Leaks

A gasket's entire purpose is to maintain a seal by creating sufficient surface stress. When bolt load is lost due to creep, this sealing stress drops.

Eventually, the stress can fall below the minimum required to contain the system pressure, resulting in a leak and joint failure.

The Solution: Moving Beyond Pure PTFE

The most effective way to mitigate creep is to choose a gasket material that is physically designed to resist it. This involves using PTFE that has been enhanced with other materials.

The Role of Fillers

Filled PTFE gaskets contain a percentage of a secondary material, or "filler," blended into the PTFE matrix. These filler particles act as a microscopic internal skeleton.

This skeleton provides structural support and physically blocks the PTFE polymer chains from sliding past one another, dramatically increasing the gasket's resistance to creep.

Common Reinforced Materials

Different fillers provide different benefits, making it possible to tailor a gasket to a specific service.

- Silica: Excellent for strong acid and general chemical applications (except hydrofluoric acid). Offers superb creep resistance.

- Glass Microspheres: A common choice for a wide range of applications, improving compression and creep properties for moderate acid and general chemical use.

- Graphite: Increases thermal conductivity and reduces creep, making it suitable for higher temperature applications and anti-static requirements.

Restructured and Expanded PTFE (ePTFE)

Another advanced solution is restructured PTFE. The manufacturing process creates a multi-directional fibrous structure within the material itself.

This internal web of fibers is inherently resistant to flow, providing excellent creep resistance and sealability even at low bolt loads, without the need for traditional fillers.

Understanding the Trade-offs

Selecting an advanced PTFE material is not without its considerations. An objective analysis requires acknowledging the trade-offs involved.

Chemical Compatibility

While fillers solve the creep problem, the filler material itself must be chemically resistant to your process fluid.

For example, a glass-filled gasket, while mechanically robust, would be quickly attacked and destroyed by hydrofluoric acid. Always verify the compatibility of both the PTFE and the filler.

Temperature and Pressure Limits

Every gasket material has a P-T (Pressure x Temperature) rating. Creep is significantly accelerated by heat.

Selecting a gasket rated for your maximum operating temperature and pressure is non-negotiable for ensuring a long-term, creep-resistant seal.

Cost vs. Risk

Filled and restructured PTFE gaskets are more expensive than their pure PTFE counterparts.

However, this initial cost must be weighed against the significant cost and safety risk associated with a joint failure, process downtime, and potential environmental impact.

How to Select the Right Creep-Resistant Gasket

To ensure a reliable, leak-free joint, match the gasket material to the demands of your system.

- If your primary focus is general industrial use with moderate temperatures: A glass or silica-filled PTFE gasket typically provides the best balance of performance and cost.

- If your primary focus is aggressive chemical service: A silica-filled or other chemically inert filled PTFE is critical to prevent both leaks and material degradation.

- If your primary focus is high-temperature, high-pressure, or critical service: A restructured PTFE (ePTFE) or a specialized graphite-filled material offers the highest level of reliability and creep resistance.

By correctly identifying your operating conditions and selecting an appropriately reinforced PTFE material, you can engineer a dependable, long-lasting seal that overcomes the inherent limitations of pure PTFE.

Summary Table:

| Solution Type | Key Materials | Primary Benefit | Ideal For |

|---|---|---|---|

| Filled PTFE | Silica, Glass, Graphite | Internal skeleton blocks polymer flow, increasing creep resistance. | General industrial, chemical service, high-temperature applications. |

| Restructured PTFE (ePTFE) | Expanded PTFE | Multi-directional fibrous structure resists flow, even at low bolt loads. | High-temperature, high-pressure, or critical service applications. |

Stop gasket failure and costly downtime. The right PTFE material is critical for a reliable seal. KINTEK specializes in manufacturing high-performance, creep-resistant PTFE components—including custom gaskets, seals, and liners—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication, from prototypes to high-volume orders, ensures you get a solution engineered for your specific temperature, pressure, and chemical requirements.

Contact KINTEK today for a consultation and let our experts help you select the perfect PTFE material for a leak-free operation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech