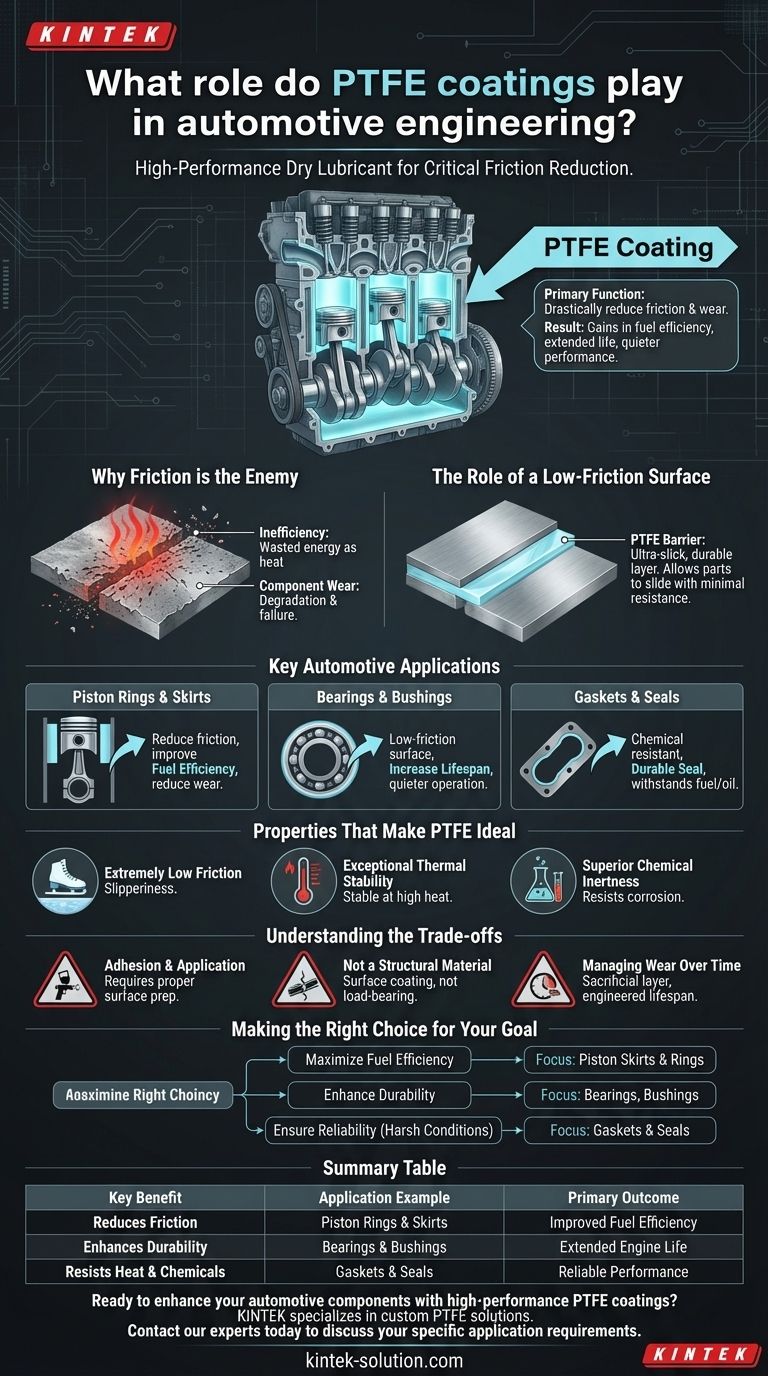

In automotive engineering, PTFE coatings serve a critical role as a high-performance dry lubricant. Their primary function is to drastically reduce friction and wear between moving parts, particularly within the engine. This single intervention leads to significant gains in fuel efficiency, extends the operational life of components, and results in quieter, more reliable engine performance.

The core value of PTFE in automotive applications is not just its famous "non-stick" quality, but its unique ability to maintain extremely low friction under the harsh conditions of high heat, intense pressure, and chemical exposure inherent to modern engines.

Why Friction is the Primary Enemy

Friction in an engine is a constant source of inefficiency and degradation. Every component that moves against another generates resistance, which translates directly into wasted energy and component wear.

The Inefficiency of Metal-on-Metal Contact

When metal parts rub against each other, a significant amount of the energy produced by combustion is lost as heat. This wasted energy directly reduces fuel economy.

The Inevitability of Component Wear

This constant rubbing action physically wears down critical surfaces over time. This degradation can lead to decreased performance, increased oil consumption, and eventual component failure.

The Role of a Low-Friction Surface

PTFE coatings act as a barrier between these metal surfaces. By creating an ultra-slick, durable layer, they allow parts to slide past one another with minimal resistance, fundamentally changing the engine's internal dynamics.

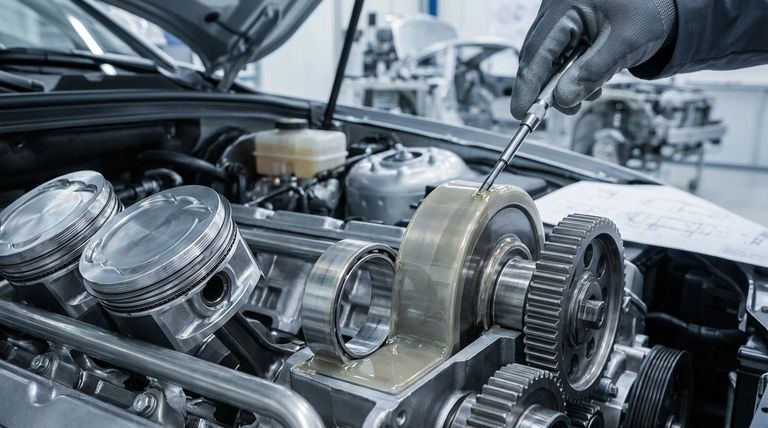

Key Automotive Applications of PTFE

PTFE is not applied randomly; it is targeted at specific components where the battle against friction and heat is most critical.

Piston Rings and Skirts

Coating piston rings and skirts with PTFE reduces the friction as the piston travels within the cylinder. This is one of the most direct ways to improve fuel efficiency and reduce engine block wear.

Bearings and Bushings

In bearings, PTFE provides a low-friction surface that can withstand the engine's rotational forces. This not only increases the lifespan of the bearings but also contributes to a quieter and smoother-running engine.

Gaskets and Seals

PTFE's excellent chemical resistance makes it an ideal material for gaskets. It creates a durable, non-reactive seal that can withstand exposure to fuel, oil, and coolant without degrading.

The Properties That Make PTFE Ideal

Several inherent characteristics make PTFE uniquely suited for the demanding automotive environment, often outperforming other polymers like Nylon or PEEK in specific areas.

Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material. This innate "slipperiness" is the primary reason for its use as a coating on moving parts.

Exceptional Thermal Stability

Engines operate at extremely high temperatures. PTFE coatings remain stable and effective across a wide temperature range where other materials would break down or fail.

Superior Chemical Inertness

The internal environment of an engine is a hostile mix of fuels, oils, and combustion byproducts. PTFE is almost completely inert, meaning it resists chemical corrosion and maintains its integrity over the long term.

Understanding the Trade-offs

While highly effective, PTFE coatings are a specialized solution with specific considerations. Understanding their limitations is key to successful application.

Adhesion and Application

The effectiveness of a PTFE coating is highly dependent on the quality of its application. Proper surface preparation is critical to ensure the coating adheres properly to the metal substrate and does not flake off under stress.

Not a Structural Material

It is crucial to remember that PTFE is a surface coating, not a structural component. It enhances the properties of the underlying metal part but does not add significant strength or load-bearing capacity on its own.

Managing Wear Over Time

While durable, PTFE coatings are sacrificial layers that can wear down over the engine's lifetime. Their formulation and thickness are engineered to match the expected lifespan of the component they protect.

Making the Right Choice for Your Goal

The decision to use a PTFE coating should be driven by a specific engineering objective.

- If your primary focus is maximizing fuel efficiency: Prioritize applying PTFE coatings to piston skirts and rings, as this directly reduces the largest sources of parasitic energy loss.

- If your primary focus is enhancing durability and engine life: Target bearings, bushings, and other high-wear rotational components to minimize material degradation over time.

- If your primary focus is ensuring reliability in harsh conditions: Utilize PTFE for gaskets and seals that are exposed to corrosive fluids or extreme temperatures.

By strategically applying PTFE's unique properties, automotive engineers can directly address the core challenges of friction, heat, and wear.

Summary Table:

| Key Benefit | Application Example | Primary Outcome |

|---|---|---|

| Reduces Friction | Piston Rings & Skirts | Improved Fuel Efficiency |

| Enhances Durability | Bearings & Bushings | Extended Engine Life |

| Resists Heat & Chemicals | Gaskets & Seals | Reliable Performance in Harsh Conditions |

Ready to enhance your automotive components with high-performance PTFE coatings?

KINTEK specializes in the precision manufacturing of custom PTFE components—including seals, liners, and specialized coatings—for the automotive, semiconductor, medical, and industrial sectors. Our expertise ensures your parts deliver superior friction reduction, thermal stability, and chemical resistance.

Whether you need prototypes or high-volume production, we can help you achieve greater efficiency and durability. Contact our experts today to discuss your specific application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry