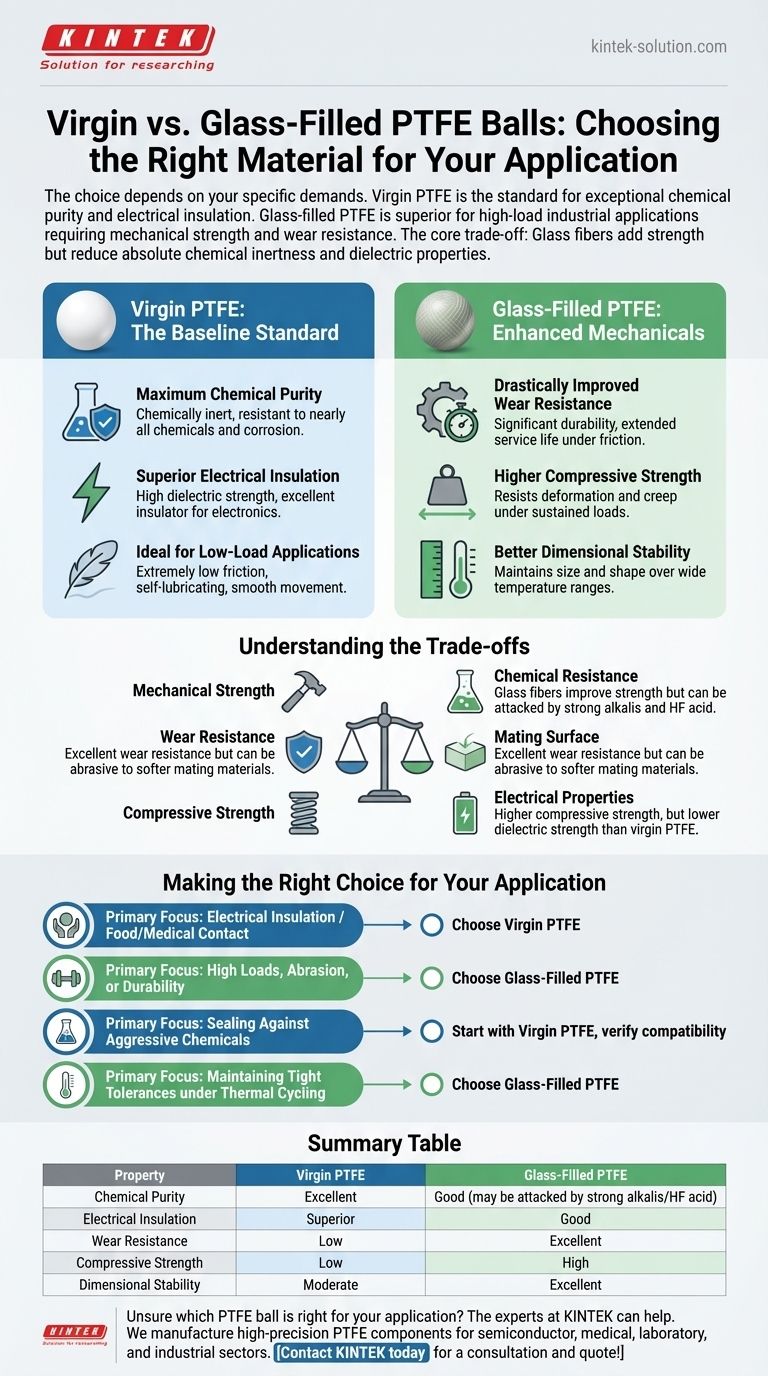

The choice between virgin and glass-filled Teflon (PTFE) balls is determined by your application's specific demands. Virgin PTFE is the standard for applications requiring exceptional chemical purity and electrical insulation, such as in laboratory or electronics settings. For high-load industrial applications where mechanical strength and wear resistance are critical, glass-filled PTFE is the superior engineering choice.

The core decision hinges on a single trade-off: The addition of glass fibers transforms soft, pure PTFE into a mechanically robust material. This enhancement in strength and wear resistance, however, comes at the cost of the absolute chemical inertness and dielectric properties found in its virgin counterpart.

Understanding Virgin PTFE: The Baseline Standard

Virgin Polytetrafluoroethylene (PTFE) is prized for its unique combination of properties in its purest state. It serves as the benchmark against which all modified versions are measured.

### Maximum Chemical Purity

Virgin PTFE is one of the most chemically inert materials known. It is resistant to nearly all industrial chemicals, weathering, and corrosion, making it ideal for use as seals or bearings in highly aggressive chemical environments.

### Superior Electrical Insulation

As an excellent electrical insulator with a high dielectric strength, virgin PTFE is a top choice for components in electronics. Its non-conductive nature prevents electrical arcing or shorts in sensitive applications.

### Ideal for Low-Load Applications

While not known for its strength, virgin PTFE's extremely low coefficient of friction makes it self-lubricating. This is highly effective in light load-bearing applications where smooth, low-friction movement is needed without external lubricants.

The Advantage of Glass-Filled PTFE: Enhanced Mechanicals

By reinforcing the PTFE matrix with glass fibers (typically 15-25%), we create a composite material with significantly improved mechanical characteristics.

### Drastically Improved Wear Resistance

The primary benefit of adding glass is a dramatic increase in wear resistance. This makes glass-filled PTFE far more durable in applications involving friction, abrasion, or frequent cycling, significantly extending the service life of the component.

### Higher Compressive Strength

Glass-filled PTFE exhibits higher hardness and much greater compressive strength. It resists deformation and creep under sustained loads far better than virgin PTFE, making it suitable for structural or high-load bearing roles.

### Better Dimensional Stability

The addition of glass fibers lowers the material's coefficient of thermal expansion. This means glass-filled PTFE balls will maintain their size and shape more consistently across a wider range of temperatures, a critical factor for maintaining tight tolerances.

Understanding the Trade-offs

Selecting the correct material requires an objective assessment of what is gained and what is compromised when glass fibers are introduced.

### Mechanical Strength vs. Chemical Resistance

While glass-filled PTFE is still highly resistant to most chemicals, it is not as universally inert as virgin PTFE. The glass fibers can be attacked by hydrofluoric acid and strong alkalis, which could compromise the component in certain specialized chemical applications.

### Wear Resistance vs. Mating Surface

The hardness that gives glass-filled PTFE its excellent wear resistance can also make it more abrasive to softer mating surfaces, such as aluminum or other plastics. This must be considered in the overall system design. Virgin PTFE is much gentler on adjacent components.

### Compressive Strength vs. Electrical Properties

The addition of glass fibers alters the dielectric properties of the PTFE. While still a good insulator for many uses, it does not match the exceptional dielectric strength of virgin PTFE, making the pure form the only choice for high-voltage or sensitive electronic insulation.

Making the Right Choice for Your Application

Your final decision should be guided by the single most critical performance requirement of your project.

- If your primary focus is electrical insulation or food/medical contact: Choose virgin PTFE for its unmatched dielectric strength and purity.

- If your primary focus is high loads, abrasion, or mechanical durability: Choose glass-filled PTFE for its superior wear resistance and compressive strength.

- If your primary focus is sealing against aggressive chemicals: Start with virgin PTFE due to its near-total chemical inertness, and only consider a filled version after verifying its specific compatibility.

- If your primary focus is maintaining tight tolerances under thermal cycling: Choose glass-filled PTFE for its lower thermal expansion and greater dimensional stability.

Understanding these fundamental material differences ensures you select a component that performs reliably, not one that becomes an unexpected point of failure.

Summary Table:

| Property | Virgin PTFE | Glass-Filled PTFE |

|---|---|---|

| Chemical Purity | Excellent | Good (may be attacked by strong alkalis/HF acid) |

| Electrical Insulation | Superior | Good |

| Wear Resistance | Low | Excellent |

| Compressive Strength | Low | High |

| Dimensional Stability | Moderate | Excellent |

Unsure which PTFE ball is right for your application? The experts at KINTEK can help. We manufacture high-precision PTFE components, including custom seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, we ensure your components meet exact performance requirements.

Contact KINTEB today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

People Also Ask

- What types of media can PTFE lined ball valves handle? Handle Corrosive Fluids Safely

- How does PTFE enhance baseball equipment? Unlock Faster Swings and Longer-Lasting Gear

- What are the best practices for tool selection when machining Teflon? Achieve Precision with the Right Tools

- What makes PTFE an excellent electrical insulator? Superior Performance for High-Frequency & High-Voltage Applications

- What factors should be considered when choosing between spiral and split PTFE backup rings?

- What makes Teflon suitable for electrical applications? Unmatched Insulation for Extreme Conditions

- What is a PTFE lined ball valve? A Corrosion-Resistant Solution for Harsh Chemicals

- What industries commonly use PTFE gaskets? Essential Sealing Solutions for Demanding Applications