The most common shapes of PTFE are industrial stock forms like sheets, rods, and tubes. These primary shapes are then used as the raw material to create a vast array of more complex, custom-machined components such as seals, gaskets, and bearings.

The key is to understand that PTFE is typically sold in simple, foundational shapes. Its true versatility comes from its unique properties, which allow these basic forms to be easily machined or molded into highly specific parts for demanding chemical, electrical, and mechanical applications.

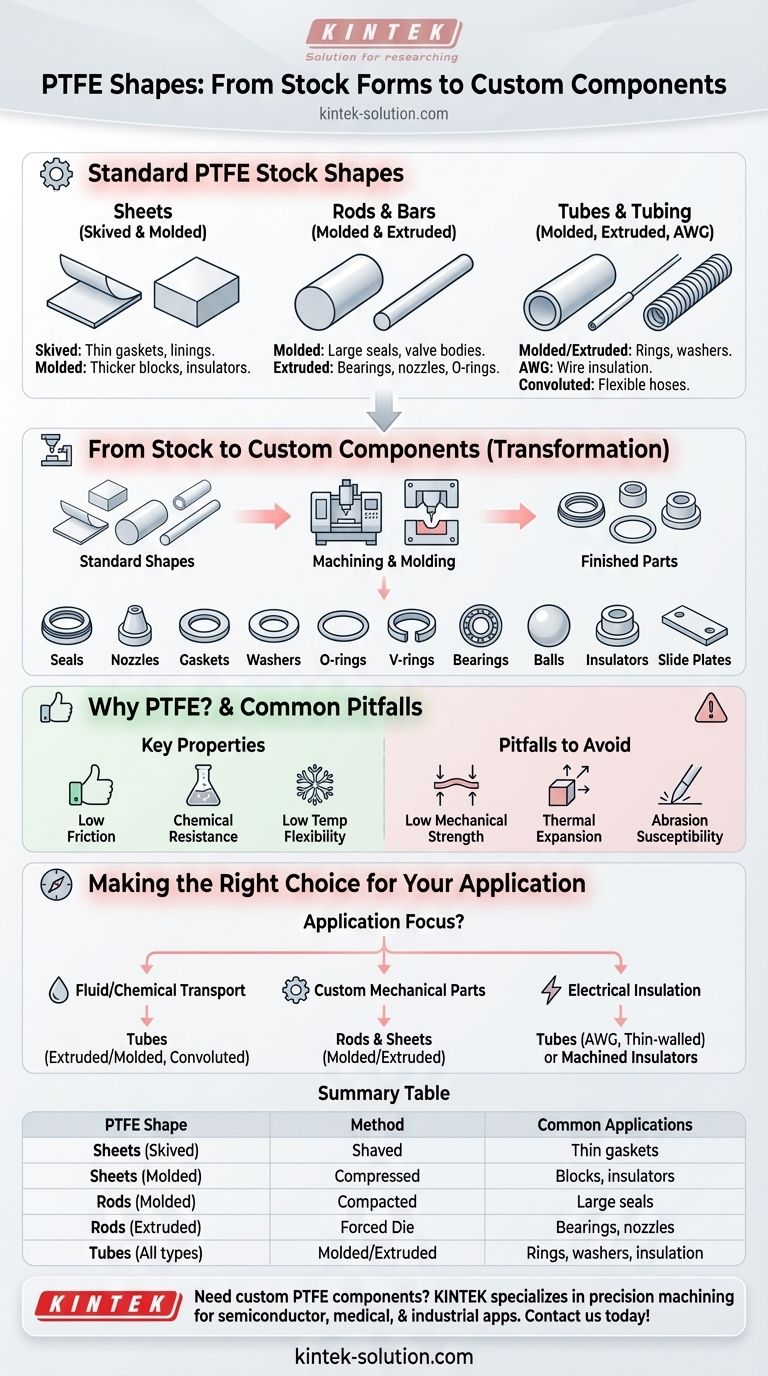

Standard PTFE Stock Shapes

PTFE is manufactured in several standard forms that serve as the starting point for fabrication. The manufacturing method—such as molding, skiving, or extruding—determines the final characteristics and dimensions of the stock shape.

Sheets (Skived and Molded)

Skived sheets are produced by shaving a thin, continuous layer from a large cylindrical block of PTFE, similar to peeling a potato. This method is ideal for creating thin sheets used for gaskets or linings.

Molded sheets are created by compressing PTFE powder in a mold under heat. This process produces thicker, more rigid sheets that are often machined into blocks, insulators, or slide plates.

Rods and Bars (Molded and Extruded)

Molded rods are made by compacting PTFE resin into a cylindrical mold. They are available in larger diameters and are well-suited for machining bigger components like large seals or valve bodies.

Extruded rods are formed by forcing PTFE resin through a die. This continuous process is efficient for producing long rods with smaller, consistent diameters, which are then machined into parts like bearings, nozzles, and O-rings.

Tubes and Tubing (Molded, Extruded, and AWG)

Molded and extruded tubes serve as the basis for hollow components like rings, washers, and valve seats, reducing material waste compared to machining from solid rod.

AWG (American Wire Gauge) size tubes are thin-walled tubes specifically designed for insulating wires and electrical components.

Convoluted tubing has a ribbed, flexible design, making it ideal for applications requiring tight bend radii, such as in chemical transfer hoses or protective conduits.

From Stock Shapes to Custom Components

The true value of PTFE is realized when these standard shapes are transformed into finished parts. Its properties make it an ideal material for custom fabrication.

The Role of Machining and Molding

Because PTFE is a relatively soft material with a waxy texture, it can be easily machined using standard metalworking equipment. This allows for the precise creation of complex geometries from rods, sheets, and tubes.

Common Machined Components

These stock shapes are the raw material for a nearly endless list of finished parts. Common examples include seals, nozzles, gaskets, washers, O-rings, V-rings, bearings, balls, insulators, and slide plates.

Why PTFE is Chosen for These Components

The reason PTFE is used for such a wide range of parts is due to its exceptional properties. It has a very low coefficient of friction, making it perfect for bearings. Its high resistance to chemicals and water is ideal for seals and linings in corrosive environments, and its flexibility at low temperatures ensures performance in extreme conditions.

Common Pitfalls to Avoid

While versatile, PTFE is not a universal solution. Understanding its limitations is critical for successful application design.

Low Mechanical Strength

PTFE is a soft material and can be prone to "creep," or deforming under a sustained load. It is not suitable for high-load structural applications without reinforcement.

Thermal Expansion

PTFE has a high rate of thermal expansion compared to metals. This must be accounted for in designs where tight tolerances are critical across a range of operating temperatures.

Susceptibility to Abrasion

While slippery, PTFE is not highly resistant to abrasion from hard particles. In abrasive environments, filled grades of PTFE are often required.

Making the Right Choice for Your Application

Selecting the correct PTFE shape depends entirely on the final component you need to create.

- If your primary focus is fluid or chemical transport: Start with extruded or molded tubes for their hollow profile and excellent chemical resistance.

- If your primary focus is creating custom mechanical parts (like seals or bearings): Begin with molded or extruded rods and sheets, as they provide the ideal stock for machining.

- If your primary focus is electrical insulation: Look for thin-walled AWG-sized tubing or machine custom insulators from sheet and rod stock.

Ultimately, the available shapes of PTFE are designed to provide a flexible and efficient starting point for nearly any application that can benefit from its remarkable properties.

Summary Table:

| PTFE Shape | Manufacturing Method | Common Applications |

|---|---|---|

| Sheets (Skived) | Shaved from a block | Thin gaskets, linings |

| Sheets (Molded) | Compressed powder | Blocks, insulators, slide plates |

| Rods (Molded) | Compacted in mold | Large seals, valve bodies |

| Rods (Extruded) | Forced through a die | Bearings, nozzles, O-rings |

| Tubes (Molded/Extruded) | Molded or extruded | Rings, washers, valve seats |

| AWG Tubes | Thin-walled extrusion | Wire and electrical insulation |

| Convoluted Tubing | Ribbed, flexible design | Chemical hoses, protective conduits |

Need a custom PTFE component for your semiconductor, medical, or industrial application? KINTEK specializes in precision machining of PTFE seals, liners, and labware from prototypes to high-volume orders. Our expertise ensures your components meet exact specifications for chemical resistance, low friction, and durability. Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability