At its core, expanded PTFE (ePTFE) handles surface irregularities through its unique combination of extreme softness and high compressibility. Unlike rigid gaskets, ePTFE deforms under pressure, allowing it to flow into and perfectly fill cracks, scratches, voids, and other imperfections on a flange face, creating a tight and reliable seal where other materials would fail.

The essential principle is that ePTFE's soft, fibrous structure allows it to conform to any surface imperfection. When compressed, these fibers interlock to form a dense, strong, and impermeable barrier, effectively eliminating potential leak paths.

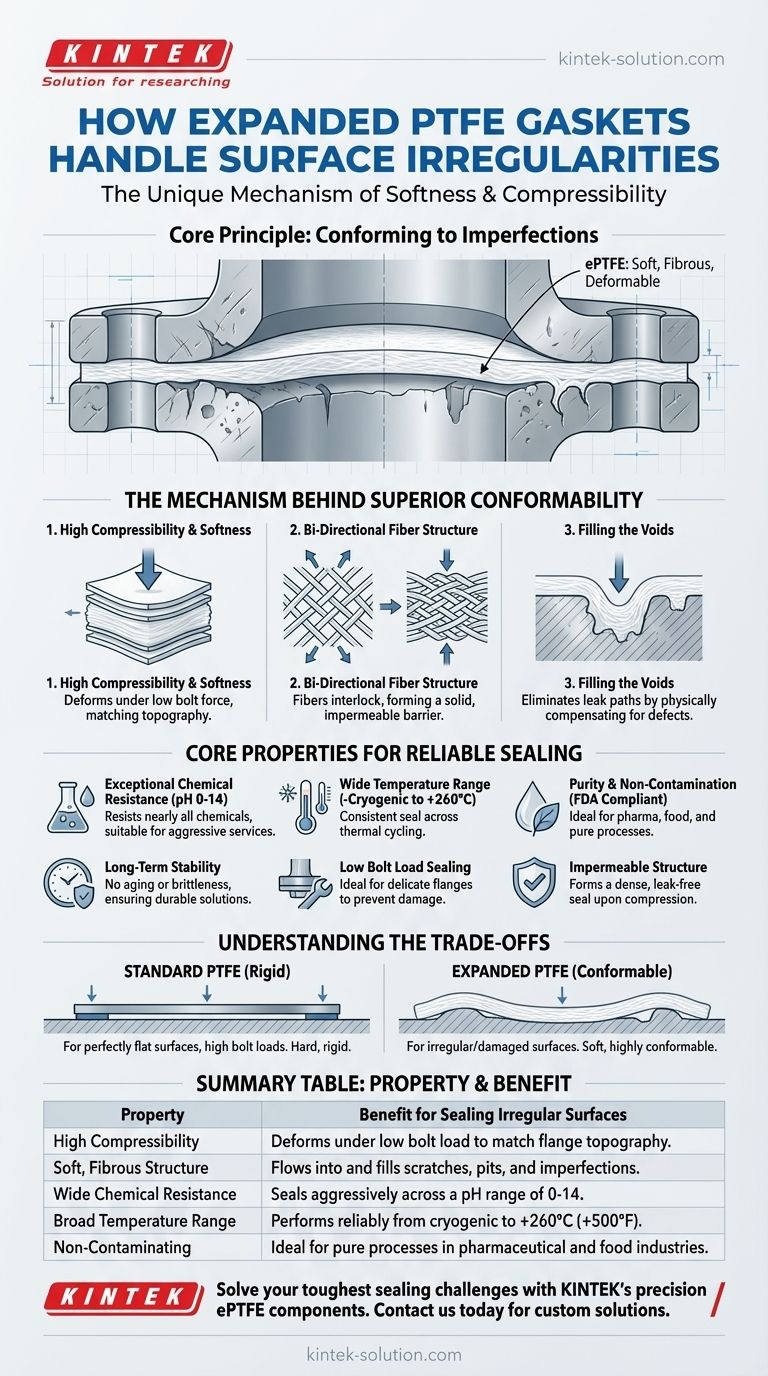

The Mechanism Behind ePTFE's Superior Conformability

To understand why ePTFE excels on imperfect surfaces, we need to look at its unique material properties. Its effectiveness comes from a combination of its physical form and its internal structure.

High Compressibility and Softness

Standard PTFE gaskets are rigid and durable. In contrast, expanded PTFE is exceptionally soft and adaptable.

This softness allows the gasket material to be easily compressed with relatively low bolt force, making it ideal for delicate flanges or applications where high torque is undesirable. It readily deforms to match the exact topography of the sealing surface.

The Role of the Bi-Directional Fiber Structure

When uncompressed, ePTFE consists of a fine, multi-directional structure of interlocking fibers that provide high elasticity.

Upon compression, these fibers lock together tightly. This process transforms the soft, pliable material into a solid, balanced, and impermeable structure that maintains its integrity even under pressure.

Filling the Voids

The combination of softness and an interlocking fibrous structure means the material effectively "cold-flows" into every groove, scratch, and pit on the flange face.

This action physically compensates for the surface imperfections, leaving no voids or gaps that could become a leak path for the process medium.

Core Properties that Make ePTFE a Reliable Choice

While its conformability is key, several other inherent properties make ePTFE a dependable choice for challenging sealing applications.

Exceptional Chemical Resistance

Expanded PTFE is resistant to nearly all chemicals across the entire pH range of 0-14.

The only notable exceptions are molten alkali metals and elemental fluorine, making it suitable for the most aggressive chemical services.

Wide Temperature Range

This material performs reliably across a vast temperature spectrum, from cryogenic conditions up to +260°C (+500°F). This stability ensures a consistent seal despite thermal cycling and extreme process temperatures.

Purity and Non-Contamination

Made from pure, virgin PTFE, these gaskets are non-contaminating, non-toxic, and compliant with FDA regulations. This is critical for applications in food processing, pharmaceuticals, and other industries where media purity is paramount.

Long-Term Stability

PTFE is not affected by weathering or aging. It has an excellent shelf life and will not become brittle or lose its sealing properties over time, ensuring a durable, long-lasting solution.

Understanding the Trade-offs

While highly effective, it's crucial to understand where ePTFE fits in comparison to other materials.

Standard vs. Expanded PTFE

The primary trade-off is between rigidity and conformability. Standard PTFE is a harder, more rigid material suited for perfectly flat, smooth surfaces that can handle high bolt loads.

Expanded PTFE is the solution for irregular, warped, or damaged surfaces precisely because it is softer and more conformable. It creates a seal with lower surface compression.

Application Pressure

While ePTFE creates an incredibly strong seal, its softness means its pressure limitations may be different from harder gasket materials in certain high-pressure applications. Always verify the manufacturer's pressure ratings for the specific style of ePTFE gasket being used.

Making the Right Choice for Your Sealing Challenge

Selecting the right gasket is about matching the material's strengths to your specific operational needs.

- If your primary focus is sealing old, damaged, or warped flanges: Expanded PTFE is the superior choice due to its unmatched ability to conform and fill imperfections.

- If your primary focus is handling aggressive chemicals or extreme temperatures: The inherent chemical inertness and wide service temperature range of ePTFE make it a highly reliable option.

- If your primary focus is protecting media purity: The non-contaminating, FDA-compliant nature of pure ePTFE ensures it will not compromise your process.

- If your primary focus is sealing delicate flanges (e.g., glass-lined, plastic): The low bolt load required to seal ePTFE makes it an ideal choice to prevent flange damage.

By understanding its unique ability to adapt to imperfect surfaces, you can confidently specify ePTFE to solve your most difficult sealing challenges.

Summary Table:

| Property | Benefit for Sealing Irregular Surfaces |

|---|---|

| High Compressibility | Deforms under low bolt load to match flange topography. |

| Soft, Fibrous Structure | Flows into and fills scratches, pits, and imperfections. |

| Wide Chemical Resistance | Seals aggressively across a pH range of 0-14. |

| Broad Temperature Range | Performs reliably from cryogenic to +260°C (+500°F). |

| Non-Contaminating | Ideal for pure processes in pharmaceutical and food industries. |

Solve your toughest sealing challenges with KINTEK's precision ePTFE components.

If you're dealing with warped, scratched, or irregular flanges in the semiconductor, medical, laboratory, or industrial sectors, our custom-fabricated expanded PTFE gaskets are engineered to provide a reliable, long-lasting seal. We combine precision production with the ability to deliver from prototypes to high-volume orders.

Contact us today to discuss your specific application and receive a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability