In essence, PTFE (Polytetrafluoroethylene) is chosen for spacers due to its unique combination of extreme chemical inertness, a very low coefficient of friction, and a wide operational temperature range. This makes it a highly reliable material that will not degrade, bind, or fail in demanding chemical, thermal, or dynamic environments.

The core reason to use a PTFE spacer is not just for one of its properties, but for its ability to provide stable, non-reactive, and low-friction separation between components, especially in environments where lesser materials would quickly fail.

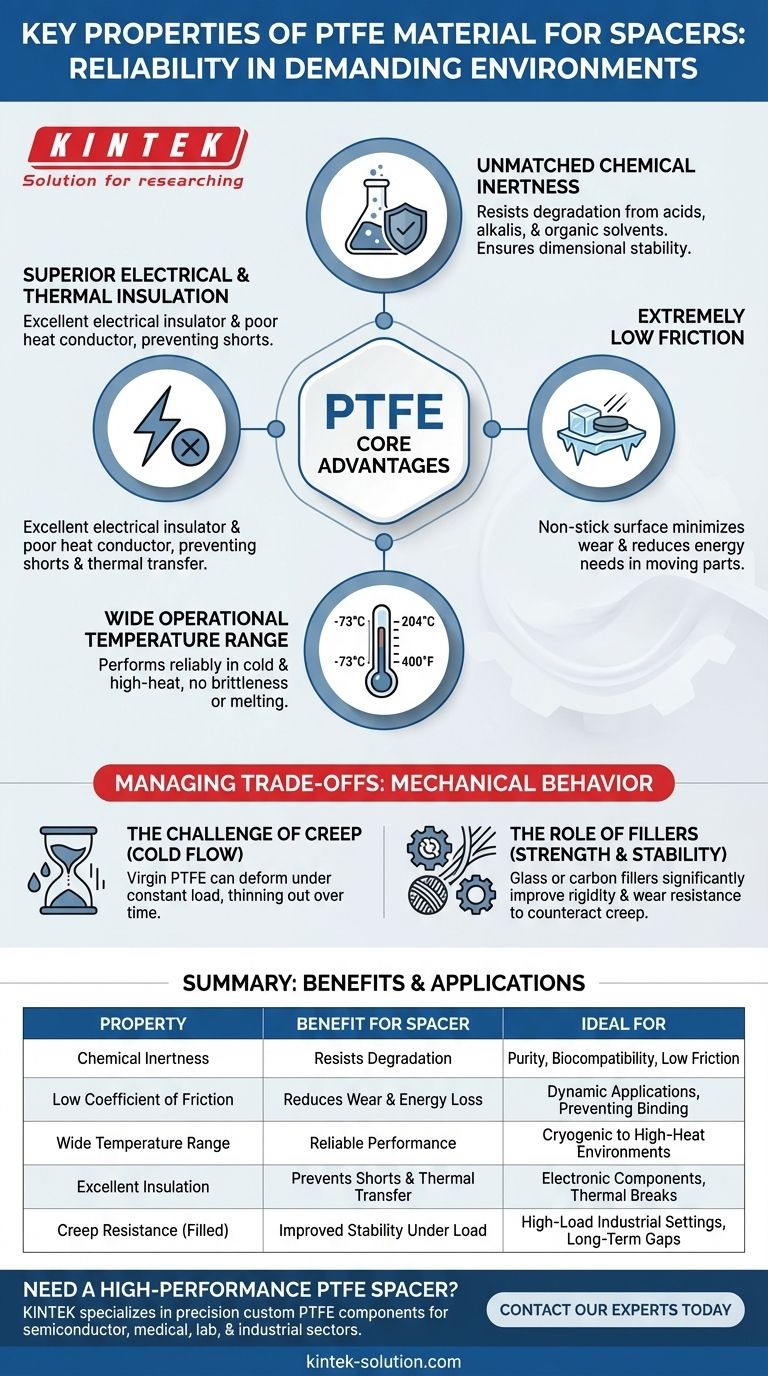

The Core Functional Properties of a PTFE Spacer

When a spacer is needed, its primary job is to maintain a precise gap and prevent unwanted interactions between two surfaces. PTFE excels in this role due to several key characteristics.

Unmatched Chemical Inertness

PTFE offers exceptional chemical resistance to nearly all industrial chemicals, including strong acids, alkalis, and organic solvents.

For a spacer, this means it will not swell, soften, or degrade when exposed to corrosive fluids or harsh cleaning agents, ensuring long-term dimensional stability.

Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This gives it a distinctly "slippery" or non-stick surface.

In applications where parts move or rotate against the spacer, this property minimizes wear and reduces the energy needed for movement.

Wide Operational Temperature Range

PTFE maintains its properties across a broad spectrum of temperatures, reliably performing from cryogenic conditions around -73°C (-100°F) up to 204°C (400°F).

This thermal stability ensures the spacer will not become brittle in the cold or melt and deform in high-heat applications, making it exceptionally versatile.

Superior Electrical and Thermal Insulation

PTFE is an excellent electrical insulator, preventing the flow of current. It is also a poor conductor of heat.

This makes PTFE spacers ideal for separating electronic components to prevent short circuits or for acting as a thermal break to minimize heat transfer between two parts.

Understanding the Trade-offs: Mechanical Limitations

While its primary properties are outstanding, the choice of PTFE must also account for its mechanical behavior, particularly for a component like a spacer that is often under load.

The Challenge of "Creep" or Cold Flow

Pure, or "virgin," PTFE is a relatively soft material. When subjected to a constant compressive force, it can slowly deform over time in a process known as creep or cold flow.

This can be a significant drawback for a spacer intended to hold a precise, long-term gap under a sustained load, as the spacer may thin out and loosen the assembly.

The Role of Fillers

To counteract creep and improve mechanical strength, PTFE is often compounded with fillers. Adding materials like glass fiber or carbon fundamentally changes the material's properties.

Filled PTFE grades offer significantly improved rigidity, wear resistance, and resistance to creep. This enhancement, however, can slightly reduce some of the material's other benefits, such as its chemical resistance or coefficient of friction.

Making the Right Choice for Your Application

Selecting the correct type of PTFE is critical and depends entirely on the primary demands of your design.

- If your primary focus is chemical purity, biocompatibility, or the lowest possible friction: Virgin (unfilled) PTFE is the correct choice for applications in food, medical, or high-purity laboratory equipment.

- If your primary focus is mechanical strength and stability under load: A filled PTFE, such as glass-filled or carbon-filled, is necessary to prevent the spacer from deforming over time.

- If your primary focus is electrical insulation: Virgin PTFE provides the best dielectric properties, but you must ensure the mechanical load on the spacer is minimal.

Ultimately, choosing the right PTFE formulation transforms it from a simple material into a precise engineering solution for your specific problem.

Summary Table:

| Property | Benefit for a Spacer |

|---|---|

| Chemical Inertness | Resists degradation from acids, solvents, and alkalis; ensures dimensional stability. |

| Low Coefficient of Friction | Reduces wear and energy loss in dynamic applications; prevents binding. |

| Wide Temperature Range | Performs reliably from -73°C to 204°C (-100°F to 400°F). |

| Excellent Insulation | Provides superior electrical insulation and acts as a thermal break. |

| Consideration: Creep | Virgin PTFE can deform under constant load; filled grades (e.g., glass) improve stability. |

Need a High-Performance PTFE Spacer for Your Critical Application?

At KINTEK, we understand that a spacer is more than just a part—it's a critical component for ensuring the reliability and performance of your entire assembly. Whether you need the ultimate chemical purity of virgin PTFE for a medical device or the superior mechanical strength of a filled PTFE formulation to resist creep in a high-load industrial setting, we have the expertise to deliver.

We specialize in the precision manufacturing of custom PTFE components for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, we prioritize the exact properties your application demands.

Let us engineer the perfect solution for you. Contact our experts today to discuss your requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support