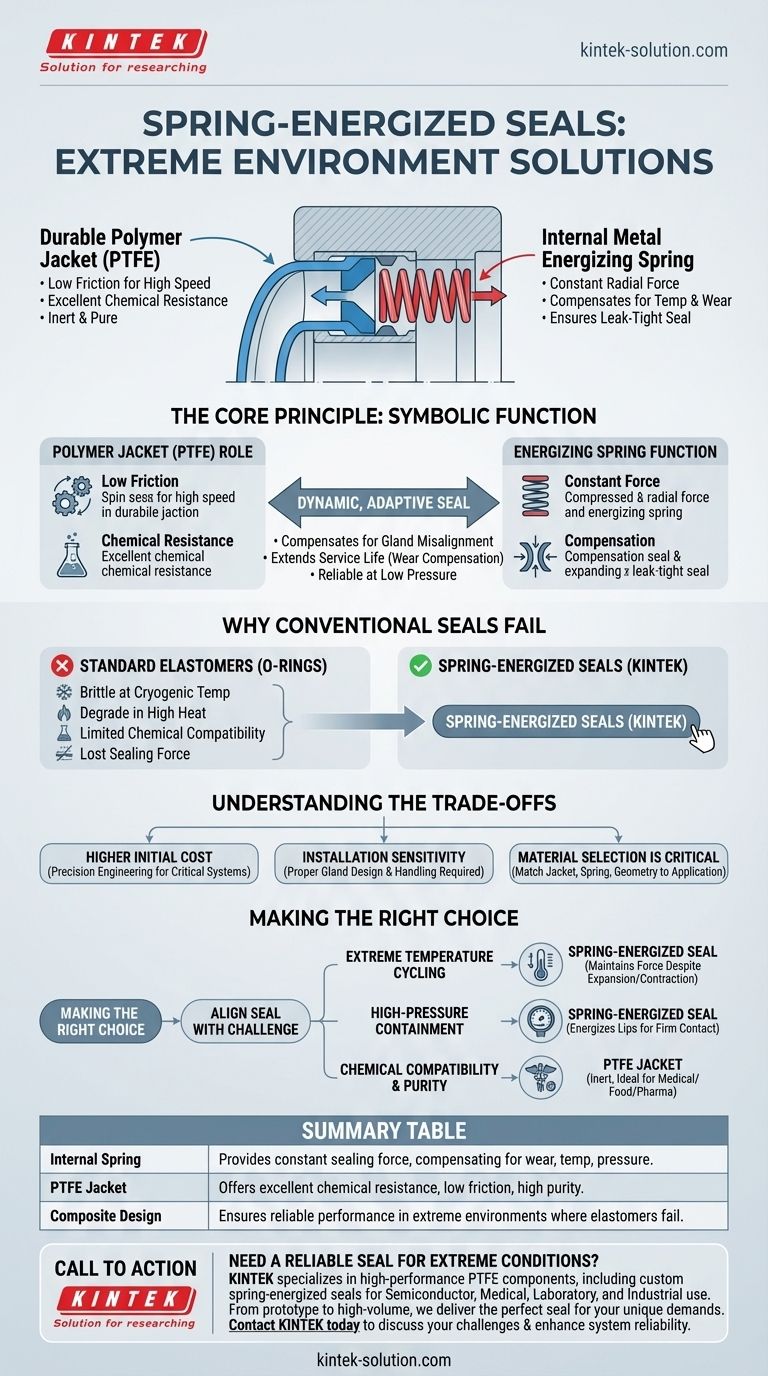

At its core, a spring-energized seal is a high-performance sealing device built from two key components: a durable polymer jacket, typically made of PTFE, and an internal metal energizing spring. This composite design creates a reliable seal in extreme environments where traditional elastomers would fail due to temperature, pressure, or chemical attack. The spring provides the consistent force needed to ensure leak-tight performance under fluctuating conditions.

The fundamental advantage of a spring-energized seal lies in the constant mechanical force provided by its internal spring. This spring ensures the polymer jacket maintains contact and integrity, even when system pressure fluctuates, temperatures swing dramatically, or the seal material itself begins to wear.

The Core Principle: How a Spring and Jacket Work in Tandem

A spring-energized seal's effectiveness comes from the symbiotic relationship between its two main parts. The design leverages the best properties of both metal and polymer to create a dynamic, adaptive seal.

The Role of the Polymer Jacket (PTFE)

The outer jacket is the primary point of contact with the system. It is most often made from Polytetrafluoroethylene (PTFE), a material known for its exceptional properties.

PTFE provides an extremely low coefficient of friction, making these seals ideal for high-speed applications where heat generation and wear are concerns.

Furthermore, its excellent chemical resistance allows it to withstand aggressive media, disinfectants, and sterilization processes that would degrade conventional rubber seals.

The Function of the Energizing Spring

The internal spring is the engine of the seal. It applies a constant radial force to the PTFE jacket, pressing its lips firmly against the mating surfaces.

This mechanical energy ensures a tight seal even at very low system pressures. It also compensates for the PTFE jacket's tendency to change dimensions with temperature.

A Dynamic, Adaptive Seal

The spring's constant force also compensates for factors that cause other seals to fail over time. It can account for minor gland misalignment or eccentricity.

Most importantly, it continues to provide force even as the seal jacket wears down from use, dramatically extending the effective service life and reliability of the seal.

Why Conventional Seals Fail in Extreme Conditions

To understand the value of spring-energized seals, it's useful to recognize where traditional options, like O-rings, fall short.

Limitations of Standard Elastomers

Standard rubber or elastomer seals are highly effective in stable, predictable environments. However, they can become brittle in cryogenic temperatures or degrade quickly in high heat.

They also have a limited range of chemical compatibility, swelling or breaking down when exposed to aggressive fluids or industrial cleaning agents.

The Problem of Lost Sealing Force

Elastomeric seals rely on their inherent elasticity to create a seal. When they contract due to cold or lose resilience due to heat or age, they can lose contact with the sealing surface, resulting in a leak path. A spring-energized seal's mechanical spring prevents this from happening.

Understanding the Trade-offs

While highly effective, spring-energized seals are specialized components. Being aware of their unique considerations is key to successful implementation.

Higher Initial Cost

As a precision-engineered solution for demanding applications, these seals typically have a higher upfront cost compared to a standard O-ring or rubber seal. This cost is justified by their extended performance and reliability in critical systems.

Installation Sensitivity

The effectiveness of a spring-energized seal is highly dependent on proper gland design and careful installation. Incorrect sizing or improper handling during installation can compromise the sealing lip and lead to premature failure.

Material Selection is Critical

The term "spring-energized seal" covers a wide range of products. Performance hinges on correctly matching the jacket material, spring material, and spring geometry to the specific application's pressure, temperature, and chemical environment. This is not a one-size-fits-all solution.

Making the Right Choice for Your Application

Selecting the correct sealing solution requires aligning the seal's capabilities with the primary challenge of your environment.

- If your primary focus is extreme temperature cycling: Choose a spring-energized seal, as the spring will maintain a consistent sealing force despite the polymer jacket's expansion or contraction.

- If your primary focus is high-pressure containment: The spring's ability to energize the seal lips ensures they remain in firm contact with the gland surfaces, preventing leaks even at high differentials.

- If your primary focus is chemical compatibility and purity: The inert PTFE jacket is the ideal choice for medical, pharmaceutical, or food processing applications where resistance to sterilization and contamination prevention are critical.

By leveraging the unique mechanical design of these seals, you can achieve unparalleled reliability in your most critical applications.

Summary Table:

| Feature | Benefit |

|---|---|

| Internal Spring | Provides constant sealing force, compensating for wear, temperature changes, and pressure fluctuations. |

| PTFE Jacket | Offers excellent chemical resistance, low friction, and high purity for demanding applications. |

| Composite Design | Ensures reliable performance in extreme environments where traditional elastomers fail. |

Need a reliable seal for extreme conditions?

KINTEK specializes in manufacturing high-performance PTFE components, including custom spring-energized seals. Our precision production ensures your seals meet the exact demands of your application—whether for semiconductor, medical, laboratory, or industrial use.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the perfect seal for temperature cycling, high pressure, or aggressive chemicals.

Contact KINTEK today to discuss your sealing challenges and discover how our expertise can enhance your system's reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments