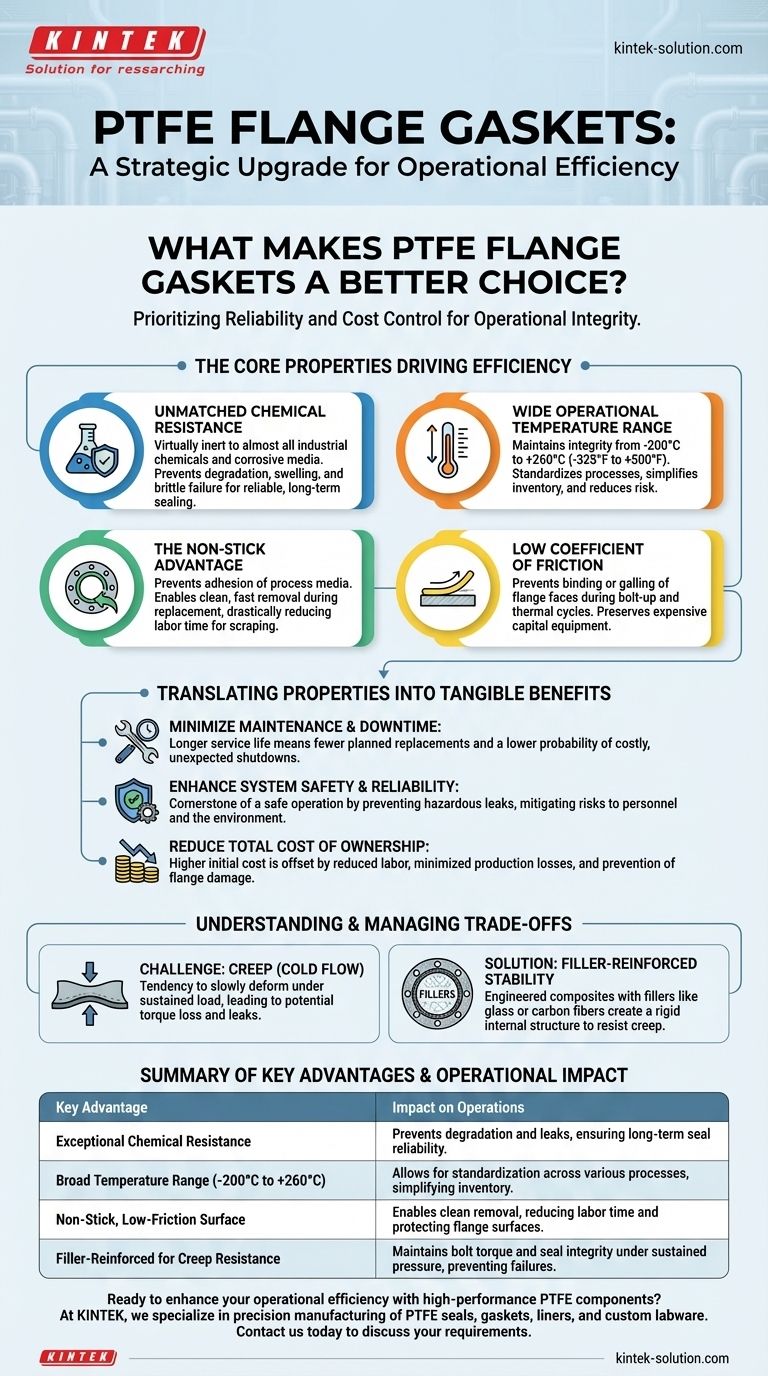

For any operation prioritizing reliability and cost control, PTFE flange gaskets represent a strategic upgrade for operational efficiency. Their effectiveness stems from a unique combination of material properties: exceptional chemical resistance, a wide temperature tolerance, and a low-friction, non-stick surface. This synergy results in longer-lasting seals, significantly reduced maintenance demands, and fewer costly, unplanned shutdowns.

Choosing a flange gasket is a decision about system-wide operational integrity. The superior properties of Polytetrafluoroethylene (PTFE) translate directly into fewer maintenance cycles, lower long-term costs, and enhanced safety, making it a tactical choice for maximizing efficiency.

The Core Properties Driving Efficiency

The operational benefits of PTFE are not accidental; they are a direct result of its fundamental molecular structure. Understanding these core properties explains why it so consistently outperforms other materials in demanding industrial environments.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals and corrosive media. This prevents the gasket material from degrading, swelling, or becoming brittle over time. A stable material ensures a reliable, long-term seal, preventing leaks that could cause hazardous spills and force emergency shutdowns.

Wide Operational Temperature Range

Standard PTFE gaskets maintain their integrity and sealing capability across an exceptionally broad temperature spectrum, typically from -200°C to +260°C (-328°F to +500°F). This versatility allows for standardization across many different plant processes—from cryogenic applications to hot fluid lines—simplifying inventory and reducing the risk of incorrect material selection.

The Non-Stick Advantage

PTFE's famously non-stick surface prevents process media, scale, or other materials from adhering to the gasket. During replacement, this allows for a clean release from the flange face, drastically reducing the labor time required for scraping and cleaning. This also protects the flange surfaces from damage that could compromise the next seal.

Low Coefficient of Friction

The extremely low friction of PTFE ensures that the gasket material does not bind or gall the flange sealing surfaces during bolt-up and thermal cycles. This prevents damage to the flange faces, which can be expensive and time-consuming to resurface, thereby preserving the integrity of the capital equipment.

Translating Properties into Tangible Benefits

These material properties are not just technical data points; they create clear and measurable advantages in day-to-day operations.

Minimizing Maintenance and Downtime

The combination of chemical, thermal, and physical durability means PTFE gaskets simply last longer than many conventional alternatives. This extended service life directly translates to fewer planned replacement cycles and, more importantly, a lower probability of unexpected failures that cause costly production downtime.

Enhancing System Safety and Reliability

A gasket that reliably maintains its seal under pressure and chemical attack is a cornerstone of a safe operation. By preventing leaks of hazardous or high-pressure fluids, PTFE gaskets mitigate risks to personnel and the environment, which is the ultimate form of operational efficiency.

Reducing Total Cost of Ownership

While PTFE gaskets may have a higher initial purchase price, they deliver a lower total cost of ownership. The savings come from reduced labor for replacement, minimized production losses from downtime, and the prevention of damage to expensive flange assets.

Understanding the Trade-offs

No material is perfect for every situation. Objectivity requires acknowledging the specific limitations of PTFE and how they are managed in high-performance designs.

The Challenge of Creep (Cold Flow)

The primary weakness of pure, unmodified PTFE is its tendency to "creep" or cold flow. Under sustained compressive load from bolts, the material can slowly deform and thin out, leading to a loss of bolt torque and a potential leak path. This effect is more pronounced at elevated temperatures.

The Importance of Fillers

To counteract creep, modern high-performance PTFE gaskets are rarely pure PTFE. They are engineered composites, incorporating fillers like glass microspheres, silica, or carbon fibers. These fillers create a rigid internal structure that dramatically improves the gasket's mechanical stability and resistance to creep, ensuring a reliable seal.

The Need for Proper Installation

Due to its unique properties, PTFE requires correct installation procedures. Proper bolt torque and tightening patterns are critical to achieving a durable seal without over-compressing the material. Inadequate installation can negate the benefits of a superior gasket.

Making the Right Choice for Your Application

Selecting the correct gasket is about aligning the material's strengths with your most critical operational goal.

- If your primary focus is handling corrosive chemicals or high-purity media: PTFE's chemical inertness is non-negotiable, preventing both gasket failure and process contamination.

- If your primary focus is minimizing maintenance cycles and labor costs: The superior longevity and clean removal of filled PTFE directly reduce long-term operational expenses.

- If your primary focus is applications with wide temperature fluctuations: PTFE's stable performance from cryogenic to high heat simplifies selection and ensures reliability across diverse processes.

- If your primary focus is the lowest initial cost for non-critical utility lines: A standard fiber or rubber gasket may be sufficient, but you must accept the trade-off of a shorter service life and more frequent monitoring.

Ultimately, specifying a PTFE flange gasket is an investment in predictable, long-term operational stability.

Summary Table:

| Key Advantage | Impact on Operations |

|---|---|

| Exceptional Chemical Resistance | Prevents degradation and leaks, ensuring long-term seal reliability. |

| Broad Temperature Range (-200°C to +260°C) | Allows for standardization across various processes, simplifying inventory. |

| Non-Stick, Low-Friction Surface | Enables clean removal, reducing labor time and protecting flange surfaces. |

| Filler-Reinforced for Creep Resistance | Maintains bolt torque and seal integrity under sustained pressure, preventing failures. |

Ready to enhance your operational efficiency with high-performance PTFE components?

At KINTEK, we specialize in the precision manufacturing of PTFE seals, gaskets, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get components that deliver superior chemical resistance, reduce maintenance cycles, and minimize costly downtime.

Contact us today to discuss your specific requirements and discover how our PTFE solutions can improve your operational reliability and total cost of ownership.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How do PTFE and NBR oil seals compare in terms of chemical resistance? A Guide to Superior Seal Performance

- What are the advantages of using PTFE Lip Seals in high-speed rotary applications? Achieve Superior Speed and Reliability

- What are the advantages of using PTFE machined parts? Solve Demanding Engineering Challenges

- Why is biocompatibility important in Medical Grade PTFE Liners? Ensuring Patient Safety and Device Success

- How do PTFE expansion bellows perform under extreme temperature conditions? Ensure System Integrity from -200°C to 260°C

- What advantages does PTFE offer in automotive applications? Enhance Vehicle Efficiency and Durability

- What are the key advantages of PTFE in medical applications? Unmatched Biocompatibility and Low Friction

- What role do PTFE rotary shaft lip seals play in the oil and gas industry? Ensure Reliability in Extreme Conditions