In automotive applications, the primary advantages of Polytetrafluoroethylene (PTFE) are its exceptionally low coefficient of friction, high heat resistance, and broad chemical inertness. This unique combination allows it to enhance vehicle efficiency, improve component durability, and ensure system reliability in the harsh operating environments found in modern vehicles.

The core value of PTFE in the automotive industry is not a single property, but its ability to solve multiple engineering challenges at once. It simultaneously reduces mechanical wear, withstands extreme temperatures, and resists degradation from corrosive fluids, making it a critical material for high-performance and long-lasting components.

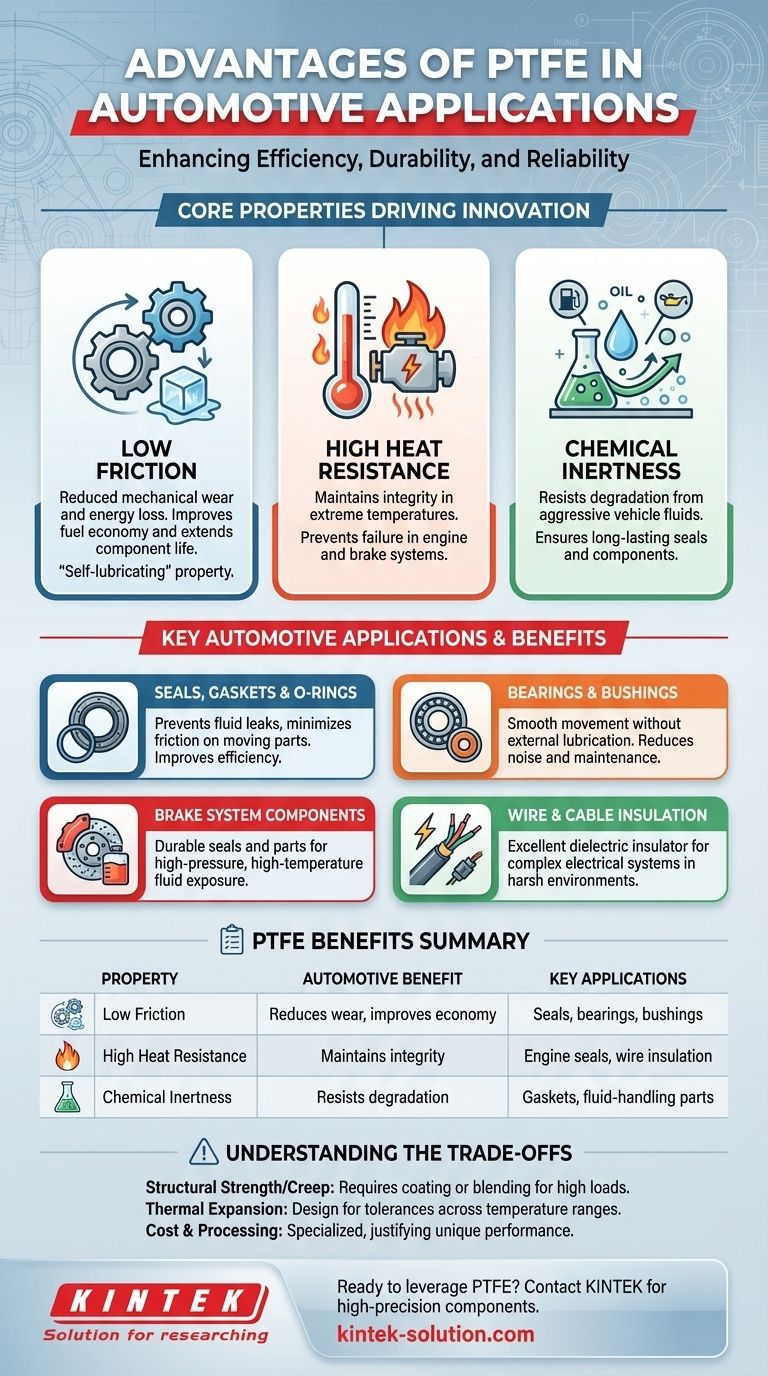

The Core Properties Driving Automotive Innovation

To understand where and why PTFE is used, we must first examine its fundamental characteristics. Three properties stand out as uniquely suited for the demands of the automotive sector.

Unmatched Friction Reduction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "self-lubricating" property is invaluable for parts that move or slide against each other.

This directly translates to reduced mechanical wear and lower energy loss, which can improve fuel economy and extend the service life of critical components.

Superior Thermal Stability

Automotive engine compartments and braking systems generate extreme heat. PTFE maintains its structural integrity and performance characteristics across a very wide temperature range.

This stability ensures that seals, gaskets, and other components do not fail, melt, or degrade when exposed to the high temperatures common in under-the-hood applications.

Exceptional Chemical Resistance

Vehicles rely on a variety of aggressive fluids, including gasoline, diesel fuel, motor oil, transmission fluid, and brake fluid. PTFE is almost completely inert and does not react with these chemicals.

This resistance prevents the material from swelling, cracking, or breaking down, ensuring that parts like seals and fluid-handling components maintain their performance and prevent leaks over the vehicle's lifespan.

Key Automotive Applications and Their Benefits

These core properties make PTFE the material of choice for several specific applications where performance and reliability are non-negotiable.

Seals, Gaskets, and O-Rings

In engines, transmissions, and steering systems, PTFE seals prevent fluid leaks while minimizing friction on moving parts like rotating shafts. This improves efficiency and prevents premature wear.

Bearings and Bushings

PTFE is used in bearings and bushings for applications like suspension systems and steering columns. Its low-friction surface allows for smooth movement without the need for external lubrication, reducing noise, vibration, and maintenance requirements.

Brake System Components

Within brake systems, PTFE's durability and chemical resistance are critical. It can be used in seals and other parts that are constantly exposed to high-pressure, high-temperature brake fluid without degrading.

Wire and Cable Insulation

Modern vehicles have complex electrical systems. PTFE's excellent dielectric properties and high heat resistance make it an ideal insulator for wiring in hot or chemically harsh environments, protecting sensitive electronics and preventing short circuits.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. An objective technical assessment requires acknowledging its limitations.

Structural Strength and Creep

PTFE is a relatively soft material and is not suitable for high-load structural applications. Under sustained pressure, it can be prone to "creep," or slow deformation over time. For this reason, it is often used as a coating or blended with other materials like glass or carbon to enhance its mechanical strength.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than most metals. Engineers must account for this in their designs, especially where tight tolerances are required across a wide temperature range, to prevent parts from binding or failing.

Cost and Processing

Compared to more common plastics, PTFE can be more expensive and require specialized processing techniques. Its use is therefore typically reserved for applications where its unique performance characteristics justify the cost.

Making the Right Choice for Your Application

Selecting PTFE should be a deliberate decision based on the primary engineering goal for a specific component.

- If your primary focus is Efficiency and Fuel Economy: Use PTFE in dynamic seals, piston rings, and bearings to minimize parasitic friction losses.

- If your primary focus is Durability and Reliability: Apply PTFE in components exposed to aggressive fluids or high heat, such as gaskets in the fuel system or seals in the engine compartment.

- If your primary focus is System Longevity: Incorporate PTFE into wear-prone components like bushings and slide plates to significantly extend their service life and reduce maintenance.

Ultimately, leveraging PTFE correctly allows engineers to build more efficient, robust, and long-lasting automotive systems.

Summary Table:

| Property | Automotive Benefit | Key Applications |

|---|---|---|

| Low Coefficient of Friction | Reduces mechanical wear, improves fuel economy | Seals, bearings, bushings |

| High Heat Resistance | Maintains integrity in extreme temperatures | Engine/brake system seals, wire insulation |

| Chemical Inertness | Resists degradation from fuels, oils, and fluids | Gaskets, O-rings, fluid-handling components |

Ready to leverage PTFE for your automotive components?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the automotive, semiconductor, medical, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get durable, efficient parts tailored to your exact needs.

Contact us today to discuss how our PTFE solutions can enhance your vehicle's performance and longevity!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are PTFE bellows and what are they made of? Solve Tough Chemical & Thermal Challenges

- What industries benefit from using PTFE rotary seals? Solve Extreme Environment Challenges

- What support and warranty options are available for custom Teflon parts? Secure Your Investment with Full Manufacturer Backing

- What is the process of CNC machining Teflon? A Guide to Mastering Precision with PTFE

- What role does PTFE's temperature resistance play in medical applications? Ensuring Sterilization & Implant Safety

- What are the main applications of PTFE slide bearing plates? Manage Structural Movement Safely

- What are the recommended cutting parameters for machining PTFE? Achieve Precision with the Right Speed, Feed, and Depth of Cut

- What are the best practices for achieving tight tolerances in PTFE machining? Master Control Over Material Instability