To put it simply, machined Polytetrafluoroethylene (PTFE) parts are chosen for their unique combination of an extremely low-friction surface, near-total chemical inertness, and stability at high temperatures. This makes PTFE an elite problem-solving material in demanding industries where other polymers or metals would quickly fail, from aerospace and medical devices to food processing.

The core advantage of PTFE isn't a single feature, but the synergy of its properties. You choose machined PTFE when you face a complex engineering challenge where low friction, chemical purity, and heat resistance are not just beneficial, but absolutely critical for the application's success.

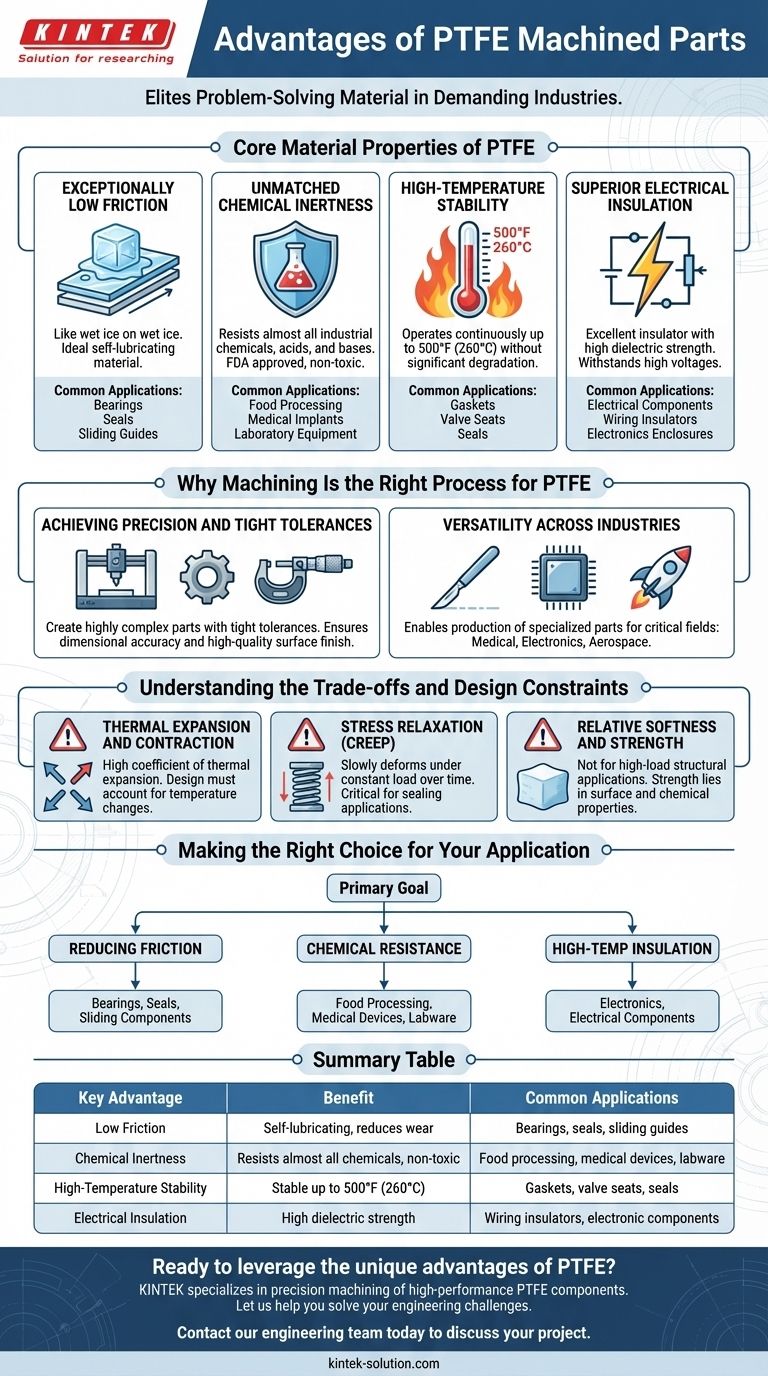

Core Material Properties of PTFE

The value of any machined part begins with the raw material itself. PTFE, commonly known by the brand name Teflon, possesses a set of intrinsic properties that make it a standout choice for specialized components.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slipperiness" is a fundamental material characteristic.

This makes it an ideal self-lubricating material for parts that slide against each other, such as bearings, seals, and sliding guides, significantly reducing wear and improving operational efficiency.

Unmatched Chemical Inertness

PTFE is highly resistant to almost all industrial chemicals, acids, and bases. It is a non-toxic and inert polymer.

This property, combined with its FDA approval, makes it the default choice for components used in food and beverage processing, medical implants, and laboratory equipment where purity and resistance to corrosion are paramount.

High-Temperature Stability

PTFE parts can operate continuously in environments up to 500°F (260°C) without significant degradation of their mechanical properties.

This thermal resistance is critical for components like gaskets, valve seats, and seals used in automotive, aerospace, and industrial machinery where high temperatures are common.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength, meaning it can withstand high voltages without breaking down.

Its insulating properties are leveraged in the manufacturing of electrical components, wiring insulators, and high-frequency electronics enclosures.

Why Machining Is the Right Process for PTFE

While the material properties are impressive, they are only useful if they can be shaped into a final part. CNC machining is the key to unlocking PTFE's full potential.

Achieving Precision and Tight Tolerances

CNC machining allows for the creation of highly complex PTFE parts with very tight tolerances, something that is difficult with other manufacturing methods for this material.

The process provides a high-quality surface finish and ensures dimensional accuracy without causing the material to warp.

Versatility Across Industries

The precision of CNC machining enables the production of specialized PTFE parts for a wide range of critical fields.

Applications include surgical instruments in the medical field, insulators for electronics, and seals and valves in aerospace, each leveraging a different combination of PTFE's core advantages.

Understanding the Trade-offs and Design Constraints

No material is perfect for every situation. While PTFE offers powerful advantages, its unique properties also introduce specific design constraints that every engineer must consider to avoid failure.

Thermal Expansion and Contraction

PTFE has a much higher coefficient of thermal expansion than most metals. This means it will expand and contract significantly with temperature changes.

Designs must account for this behavior, especially when a PTFE part is assembled with a metal component, to avoid stress, warping, or failure of the assembly.

Stress Relaxation (Creep)

Under a constant load or compressive force, PTFE has a tendency to slowly deform over time, a phenomenon known as creep or stress relaxation.

This is a critical consideration for applications like gaskets and seals, where the part must maintain a constant sealing pressure over its entire service life. The design must accommodate this material behavior.

Relative Softness and Strength

While durable and wear-resistant, PTFE is a relatively soft material compared to engineering plastics like PEEK or metals. It is not suitable for high-load structural applications.

Its strength lies in its surface and chemical properties, not in its ability to bear significant mechanical weight or impact.

Making the Right Choice for Your Application

Selecting the right material requires a clear understanding of your project's primary goal.

- If your primary focus is reducing friction in a moving assembly: PTFE's self-lubricating properties make it an ideal choice for bearings, seals, and sliding components.

- If your primary focus is chemical resistance and purity: Its inertness and FDA-approved status make it the default material for food processing, medical devices, and laboratory equipment.

- If your primary focus is high-temperature electrical insulation: PTFE's excellent dielectric strength and thermal stability are critical for demanding electronics and electrical components.

By understanding both its powerful advantages and its specific design constraints, you can leverage machined PTFE to solve some of the most demanding engineering challenges.

Summary Table:

| Key Advantage | Benefit | Common Applications |

|---|---|---|

| Low Friction | Self-lubricating, reduces wear | Bearings, seals, sliding guides |

| Chemical Inertness | Resists almost all chemicals, non-toxic | Food processing, medical devices, labware |

| High-Temperature Stability | Stable up to 500°F (260°C) | Gaskets, valve seats, seals |

| Electrical Insulation | High dielectric strength | Wiring insulators, electronic components |

Ready to leverage the unique advantages of PTFE for your critical application?

KINTEK specializes in the precision machining of high-performance PTFE components like seals, liners, and custom labware. We understand the critical balance of properties required for success in the semiconductor, medical, laboratory, and industrial sectors.

Our expertise ensures your parts are manufactured to the highest standards of accuracy, from initial prototypes to high-volume production runs. Let us help you solve your most demanding engineering challenges with a material solution that delivers.

Contact our engineering team today to discuss your project requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments