The defining characteristic of a PTFE waffle seal is its textured, grid-like sealing surface. Unlike a standard flat seal, this "waffle" pattern is engineered to actively trap and isolate foreign particles like dust or debris, providing a tight seal while simultaneously protecting the mating surfaces and the system's interior from contamination.

A PTFE waffle seal is a specialized component designed for a dual purpose: it creates a reliable, low-friction seal and acts as a built-in filter to capture contaminants at the sealing interface. This makes it ideal for machinery operating in dirty or particulate-heavy environments.

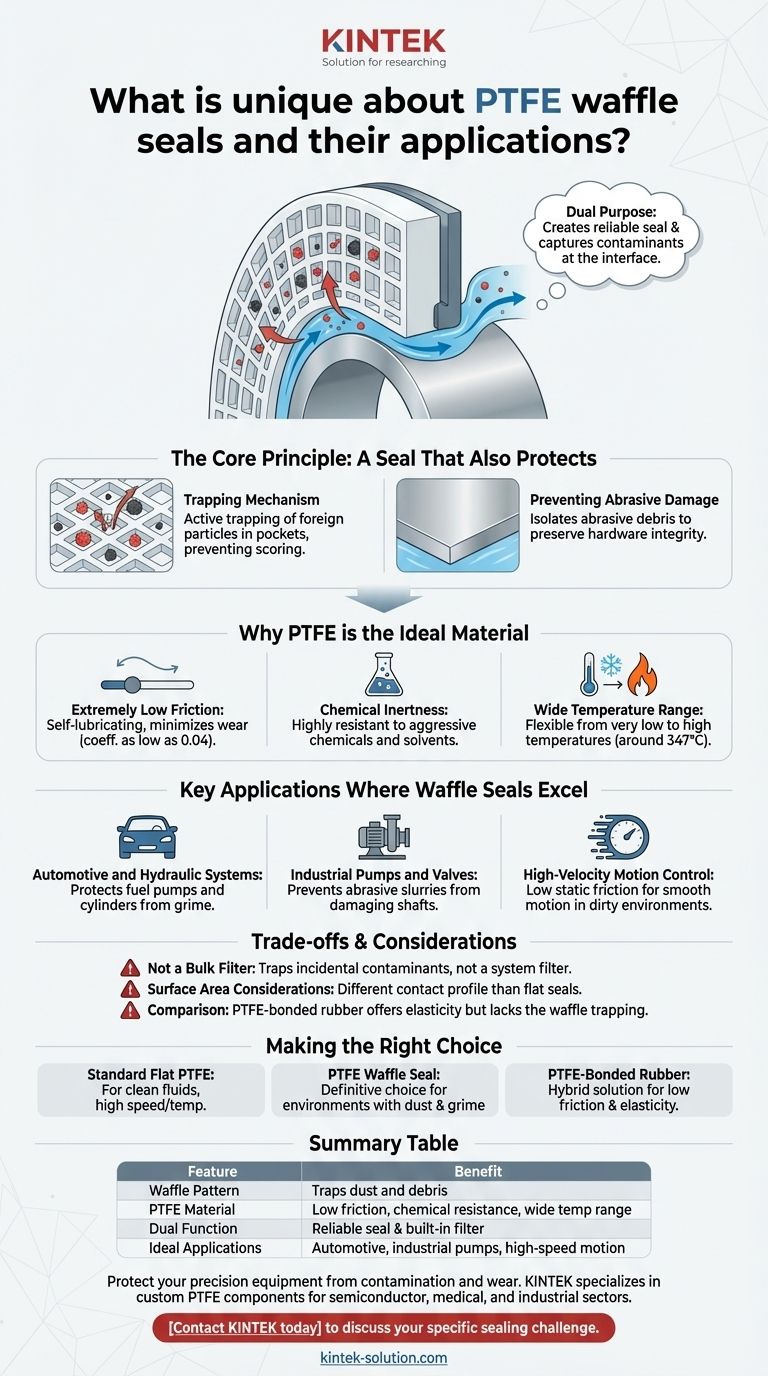

The Core Principle: A Seal That Also Protects

Standard seals work by creating a barrier. A waffle seal enhances this by adding a defensive mechanism directly into its design.

The Trapping Mechanism

The waffle pattern consists of a series of small pockets or grooves on the face of the seal. When contaminants encounter the seal, they are captured within these pockets instead of being dragged across the sensitive mating surfaces, which could cause scoring, wear, and eventual seal failure.

Preventing Abrasive Damage

This trapping function is critical in dynamic applications with reciprocating or rotating parts. By isolating abrasive particles, the waffle seal preserves the integrity of both the seal itself and the expensive hardware it protects.

The Foundation: Why PTFE is the Ideal Material

The waffle design is powerful, but its effectiveness is magnified by the inherent properties of Polytetrafluoroethylene (PTFE).

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often cited as low as 0.04. This self-lubricating quality minimizes heat generation and wear, making it perfect for high-speed dynamic applications where friction is a primary concern.

Chemical Inertness

PTFE is highly resistant to aggressive chemicals, acids, and solvents. This allows waffle seals to be used in demanding chemical processing industries for sealing shafts in pumps and valves, where they prevent leaks in high-pressure environments containing corrosive fluids.

Wide Temperature Range

With a high melting point around 347°C (657°F) and the ability to remain flexible at very low temperatures, PTFE seals are exceptionally versatile. They maintain their integrity and sealing capability across a broad spectrum of operating conditions.

Key Applications Where Waffle Seals Excel

The combination of the protective waffle pattern and PTFE's robust properties makes these seals the superior choice in specific, challenging environments.

Automotive and Hydraulic Systems

In components like steering systems, fuel injection pumps, and hydraulic cylinders, fluid cleanliness is paramount. Waffle seals protect these systems from internal wear particles and external road grime, extending the life of the equipment.

Industrial Pumps and Valves

When handling fluids that are not perfectly pure, such as slurries or chemicals with suspended solids, the waffle seal prevents these particles from damaging the pump shaft or valve stem, ensuring a longer-lasting, leak-free seal.

High-Velocity Motion Control

In high-speed pneumatic or hydraulic cylinders, the low static friction of PTFE allows for smooth, predictable motion. The waffle pattern adds a layer of protection against any contaminants that could disrupt this precision movement.

Understanding the Trade-offs

While highly effective, the waffle seal design is not a universal solution. It's important to understand its specific purpose and limitations.

Not a Bulk Filter

The waffle pattern is designed to trap incidental contaminants at the sealing point. It is not a replacement for a dedicated system filter and can become saturated in environments with extremely high levels of continuous contamination.

Surface Area Considerations

By design, the textured surface has a different contact profile than a flat seal. In applications requiring maximum surface contact for extremely high pressures with perfectly clean media, a standard flat PTFE seal might be considered.

Comparison to Other Hybrids

For applications needing the elasticity of rubber combined with PTFE's low friction, a PTFE-bonded rubber seal is a common alternative. This design, however, lacks the specific particle-trapping feature of the waffle pattern.

Making the Right Choice for Your Goal

Selecting the correct seal depends entirely on the operational environment and performance priorities.

- If your primary focus is sealing clean fluids in high-speed or high-temperature systems: A standard flat PTFE seal is often the most direct and effective solution.

- If your primary focus is sealing in an environment with potential for dust, grime, or particulate contamination: The PTFE waffle seal offers superior protection and is the definitive choice.

- If your primary focus is combining low-friction sealing with high mechanical compliance and elasticity: A PTFE-bonded rubber seal provides a hybrid solution that excels in these conditions.

Ultimately, choosing a PTFE waffle seal is a strategic decision to proactively manage contamination at the most critical points in your system.

Summary Table:

| Feature | Benefit |

|---|---|

| Waffle Pattern | Traps dust and debris to protect mating surfaces from abrasive damage. |

| PTFE Material | Provides extremely low friction, chemical resistance, and a wide temperature range. |

| Dual Function | Creates a reliable seal while acting as a built-in filter at the interface. |

| Ideal Applications | Automotive systems, industrial pumps/valves, and high-speed motion control. |

Protect your precision equipment from contamination and wear.

KINTEK specializes in manufacturing high-performance PTFE components, including custom waffle seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production ensures you get a seal that delivers superior protection and longevity, from prototype to high-volume orders.

Contact KINTEK today to discuss your specific sealing challenge and receive a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the benefits of PTFE backup rings? Enhance Seal Life in High-Pressure Systems

- How do PTFE gaskets improve coupling efficiency? Maximize Uptime & Safety in Harsh Chemical Processes

- What are the characteristics of virgin PTFE gaskets? The Ultimate Guide to Pure PTFE Performance

- How is Teflon coating utilized in security and detection? Enhancing Reliability in Demanding Environments

- What are the physical properties of PTFE balls? A Guide to Extreme Chemical & Thermal Performance

- What are the benefits of using custom Teflon parts for clients? Reduce Costs & Boost Reliability

- What makes PTFE envelope gaskets appropriate for food and pharmaceutical applications? Ensure Purity and Compliance

- In which industries are EPTFE gaskets commonly used? Critical Sealing Solutions for Demanding Environments