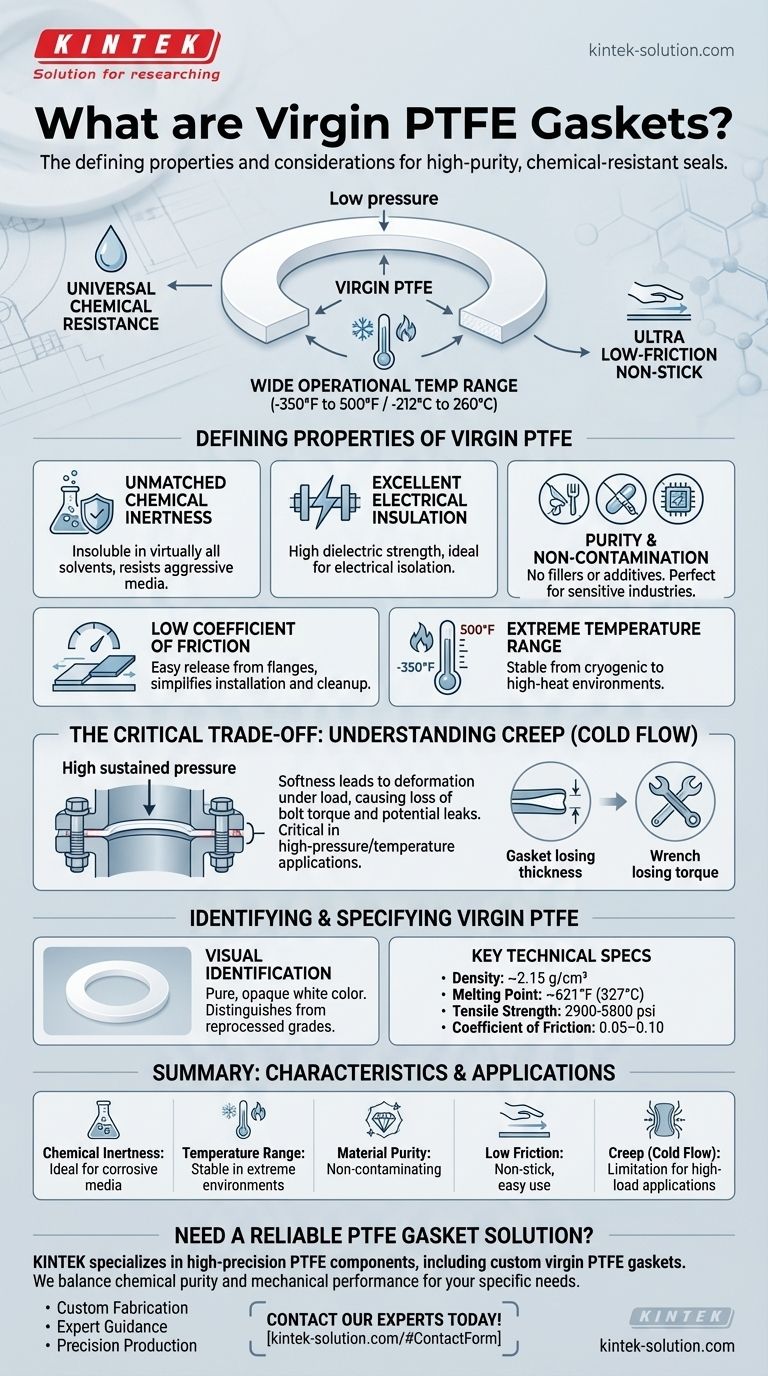

In short, virgin PTFE gaskets are defined by their 100% pure, unfilled Polytetrafluoroethylene composition. This purity gives them three primary characteristics: nearly universal chemical resistance, a very wide operational temperature range, and an extremely low-friction, non-stick surface.

The central takeaway is that while virgin PTFE offers unparalleled chemical purity and temperature resilience, its defining limitation is its softness. This makes it susceptible to "creep" or "cold flow," where the material deforms under sustained pressure, a critical factor for any high-load sealing application.

The Defining Properties of Virgin PTFE

Virgin PTFE is not just one characteristic but a unique combination of properties derived directly from its pure, additive-free chemical structure. Understanding these traits is key to using it effectively.

Unmatched Chemical Inertness

Virgin PTFE is almost completely chemically inert. It is highly insoluble in virtually all solvents and will not degrade when exposed to even the most aggressive chemicals.

This makes it a default choice for systems handling a wide variety of corrosive media.

Wide Operational Temperature Range

This material maintains its stability and integrity across an exceptionally broad temperature spectrum.

It is reliably used in applications from cryogenic levels around -350°F (-212°C) up to high-heat environments of 500°F (260°C).

Purity and Non-Contamination

Because it contains no fillers, plasticizers, or pigments, virgin PTFE is ideal for high-purity applications.

Its non-contaminating nature is why it is heavily specified in the food and beverage, pharmaceutical, and semiconductor industries.

Low Coefficient of Friction

Virgin PTFE has one of the lowest coefficients of friction of any solid material, giving it a signature non-stick quality.

This property ensures an easier release from flange surfaces, simplifying installation, removal, and cleanup.

Excellent Electrical Insulation

As a material with high dielectric strength, virgin PTFE is an exceptional electrical insulator. This makes it valuable for applications where electrical isolation is required between flanges.

The Critical Trade-off: Understanding Creep

The greatest strength of virgin PTFE—its pure, soft, and formable nature—is also the source of its primary weakness. This trade-off must be managed for a successful seal.

What is Creep or Cold Flow?

Being an extremely soft material, virgin PTFE has a tendency to "creep" or "cold flow" when subjected to compressive force.

This means the gasket material will slowly and permanently deform or "squeeze out" from under the load of the flange bolts over time.

The Practical Implications

Creep results in a loss of bolt torque, which reduces the compressive sealing force on the gasket.

In applications with pressure fluctuations or thermal cycling, this can eventually lead to leaks as the gasket no longer maintains adequate stress to fill imperfections in the flange face.

When Creep Becomes a Problem

This issue is most pronounced in applications involving high pressure, elevated temperatures, or significant temperature swings. For low-pressure, ambient temperature chemical services, it is often a non-issue.

Identifying and Specifying Virgin PTFE

Properly identifying and specifying the material ensures you are getting the performance characteristics you expect.

Visual Identification

Virgin grade PTFE is recognizable by its pure, opaque white color. This distinguishes it from mechanical grades of PTFE, which often have a slightly off-white or grayish tint due to the inclusion of reprocessed materials.

Key Technical Specifications

When reviewing a material data sheet, look for these typical properties for virgin PTFE:

- Density: Approximately 2.15 g/cm³

- Melting Point: Around 621°F (327°C)

- Tensile Strength: 2900-5800 psi (20-40 MPa)

- Coefficient of Friction: 0.05–0.10

Making the Right Choice for Your Application

Selecting the right gasket material depends entirely on your operational demands. The decision to use virgin PTFE should be based on a clear understanding of its strengths and weaknesses.

- If your primary focus is purity and chemical compatibility: Virgin PTFE is an excellent choice, especially in low-pressure systems common in food, beverage, and pharmaceutical processing.

- If your primary focus is high-pressure or high-temperature sealing: You must account for virgin PTFE's tendency to creep; consider filled PTFE grades or alternative materials for services with high bolt loads or thermal cycling.

Understanding this balance between chemical purity and mechanical stability is the key to successfully deploying virgin PTFE gaskets.

Summary Table:

| Characteristic | Description | Key Benefit / Limitation |

|---|---|---|

| Chemical Inertness | Resistant to virtually all chemicals | Ideal for corrosive media |

| Temperature Range | Stable from -350°F to 500°F (-212°C to 260°C) | Suitable for extreme environments |

| Material Purity | 100% pure PTFE, no fillers | Non-contaminating for sensitive industries |

| Low Friction | Very low coefficient of friction | Non-stick, easy installation/removal |

| Creep (Cold Flow) | Soft material deforms under sustained pressure | Limitation for high-pressure/high-load applications |

Need a reliable PTFE gasket solution tailored to your specific application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom virgin PTFE gaskets. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we understand the critical balance between chemical purity and mechanical performance.

We offer:

- Custom Fabrication: From prototypes to high-volume orders.

- Expert Guidance: Helping you select the right material (virgin or filled PTFE) based on your pressure, temperature, and chemical compatibility needs.

- Precision Production: Ensuring quality and reliability for your most demanding applications.

**Let's discuss your project requirements and find the optimal sealing solution. Contact our experts today!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications