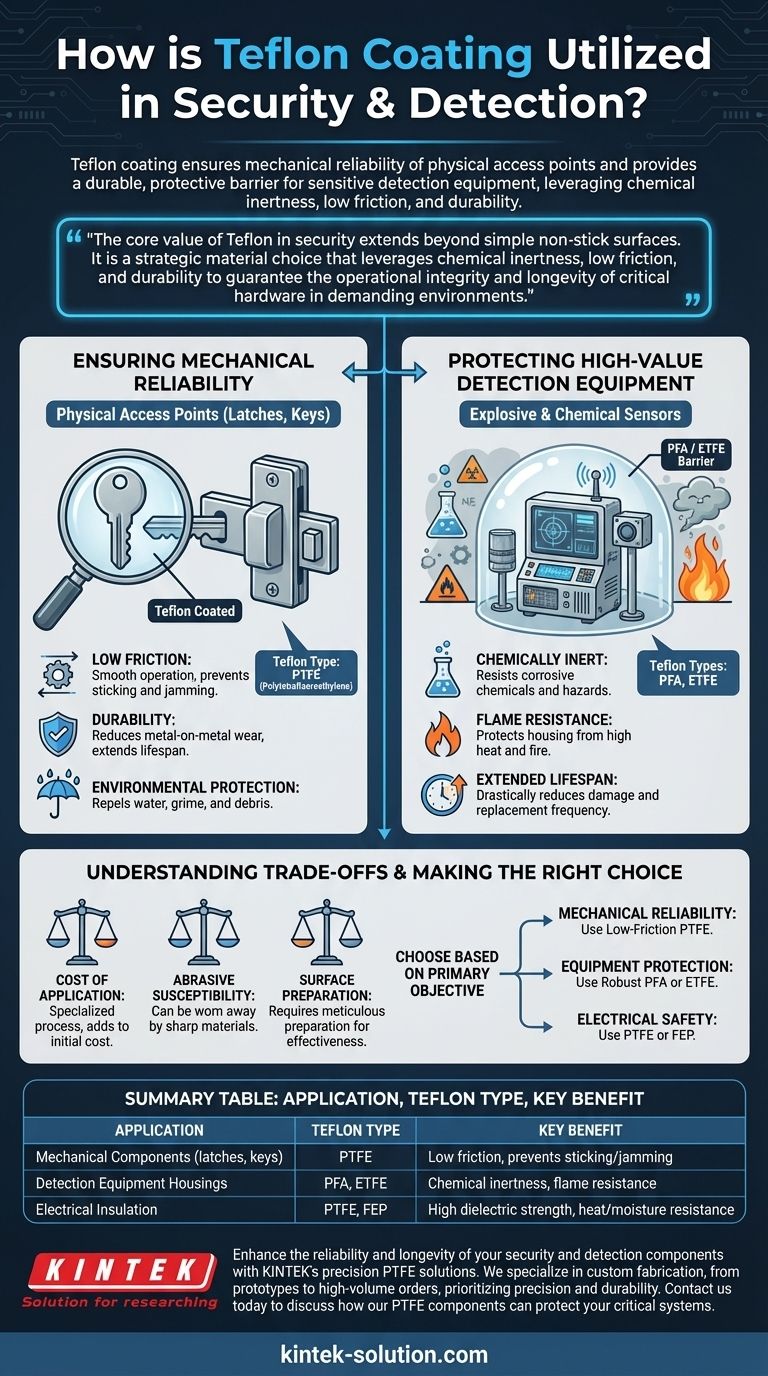

In security and detection, Teflon coating is utilized for two primary functions: ensuring the mechanical reliability of physical access points like door latches and keys, and providing a durable, protective barrier for sensitive equipment that detects explosives or hazardous chemicals. Its unique properties prevent moving parts from sticking while shielding delicate electronics from corrosive or explosive events.

The core value of Teflon in security extends beyond simple non-stick surfaces. It is a strategic material choice that leverages chemical inertness, low friction, and durability to guarantee the operational integrity and longevity of critical hardware in demanding environments.

Ensuring Mechanical Reliability

In any security system, the failure of a simple mechanical component can render the entire system vulnerable. Teflon coatings directly address the most common points of mechanical failure.

The Challenge of Environmental Exposure

Door latches, bolts, and keys are constantly exposed to moisture, dust, and temperature fluctuations. This exposure can lead to corrosion, grime buildup, and freezing, causing the mechanism to stick, jam, or fail entirely.

Low Friction for Smooth Operation

Teflon's defining characteristic is its extremely low coefficient of friction. When applied to keys and internal latch components, it creates a slick, non-stick surface that repels water and prevents debris from adhering, ensuring a smooth and reliable operation every time.

Durability Against Wear and Tear

Security components are subject to repeated use. The coating acts as a dry lubricant and a durable, sacrificial layer that reduces metal-on-metal wear, significantly extending the functional lifespan of the lock mechanism.

Protecting High-Value Detection Equipment

In industrial or high-threat environments, devices that detect explosives or dangerous chemicals are both critical and vulnerable. Protecting this equipment is essential for safety and operational continuity.

The Hostile Operating Environment

Detection equipment often operates in the very environments it is designed to monitor. This means direct exposure to corrosive chemicals or the potential for proximity to a small explosion, which can destroy sensitive and expensive machinery.

A Chemically Inert and Resistant Shield

Specialized Teflon coatings, such as PFA (perfluoroalkoxy alkane) and ETFE (ethylene tetrafluoroethylene), are chosen for their exceptional chemical and flame resistance. This coating creates a non-reactive barrier that protects the equipment's housing and internal components from damage.

Extending Equipment Lifespan

By shielding detection hardware from its hazardous environment, the coating drastically reduces damage and corrosion. This directly lowers the frequency of costly equipment replacement and ensures the device is ready and functional when needed most.

Understanding the Trade-offs

While highly effective, implementing Teflon coatings involves specific considerations that must be weighed.

Cost of Application

Industrial-grade coatings like PFA and ETFE are a specialized, multi-step process. This adds to the initial manufacturing cost of the security device compared to using uncoated materials.

Susceptibility to Abrasives

Though durable against friction and chemical exposure, Teflon coatings can be scratched or worn away by sharp or highly abrasive materials. In environments with significant abrasive particulate, the coating's lifespan may be reduced.

Need for Proper Surface Preparation

For a Teflon coating to be effective, the underlying substrate (usually metal) must be meticulously prepared. Improper application can lead to the coating peeling or flaking, completely negating its protective benefits.

Making the Right Choice for Your Goal

Selecting the correct approach depends entirely on the specific security objective you need to achieve.

- If your primary focus is mechanical reliability: A low-friction PTFE coating is the ideal choice for ensuring smooth, long-term operation in components like locks, latches, and bolts.

- If your primary focus is protecting sensitive equipment: Use a robust PFA or ETFE coating for its superior durability and chemical inertness in harsh threat-detection environments.

- If your primary focus is electrical safety: PTFE or FEP are excellent for encasing wiring in security systems due to their high dielectric strength and resistance to heat and moisture.

Ultimately, applying the right Teflon coating is a strategic decision to enhance the fundamental reliability and resilience of your security infrastructure.

Summary Table:

| Application | Teflon Type | Key Benefit |

|---|---|---|

| Mechanical Components (latches, keys) | PTFE | Low friction, prevents sticking/jamming |

| Detection Equipment Housings | PFA, ETFE | Chemical inertness, flame resistance |

| Electrical Insulation | PTFE, FEP | High dielectric strength, heat/moisture resistance |

Enhance the reliability and longevity of your security and detection components with KINTEK's precision PTFE solutions.

Whether you need custom PTFE seals, liners, or labware for the semiconductor, medical, or industrial sectors, our expertise in high-performance materials ensures your equipment operates flawlessly in the most demanding conditions.

We specialize in custom fabrication from prototypes to high-volume orders, prioritizing precision and durability.

Contact us today to discuss how our PTFE components can protect your critical systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments