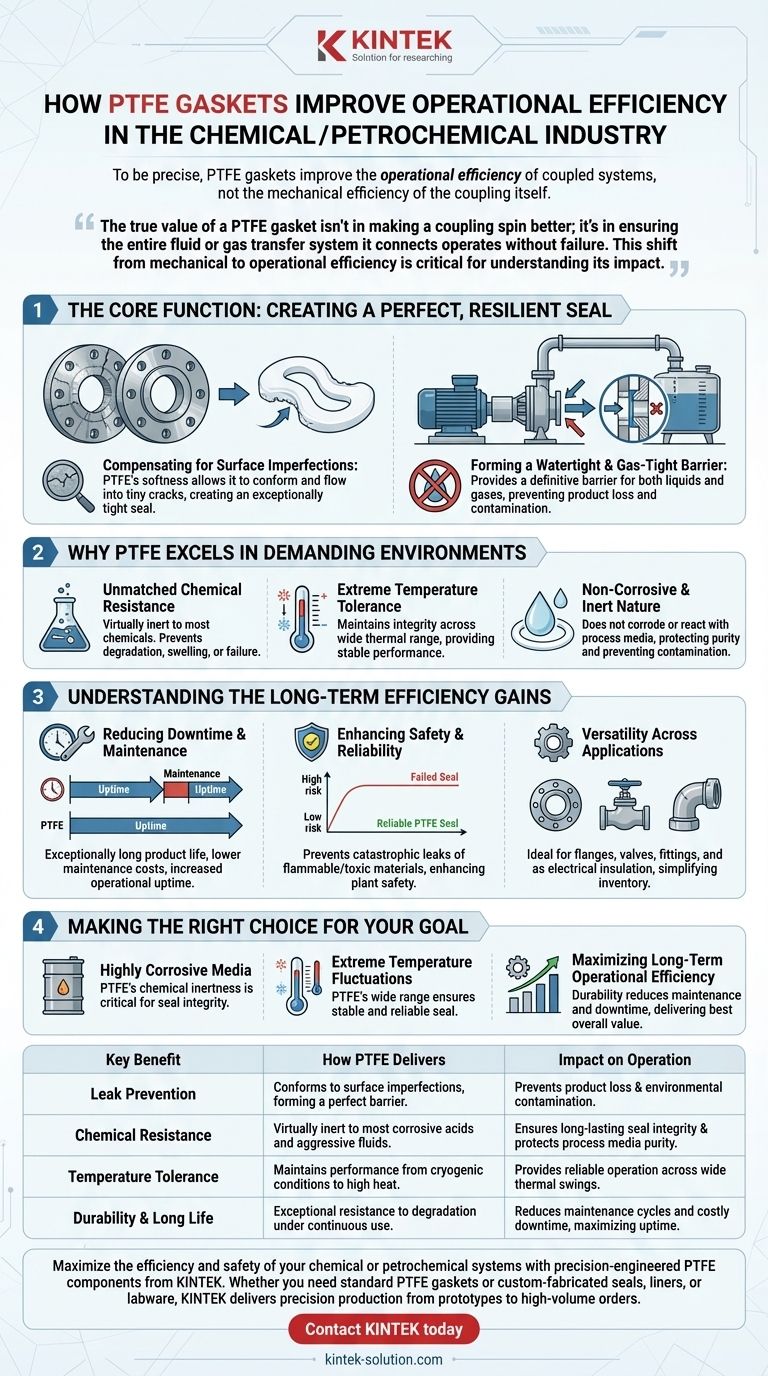

To be precise, PTFE gaskets improve the operational efficiency of coupled systems, not the mechanical efficiency of the coupling itself. They achieve this by creating a superior, leak-proof seal that prevents the loss of valuable products, minimizes costly downtime, and enhances overall system safety and reliability in harsh chemical and petrochemical environments.

The true value of a PTFE gasket isn't in making a coupling spin better; it's in ensuring the entire fluid or gas transfer system it connects operates without failure. This shift from mechanical to operational efficiency is critical for understanding its impact.

The Core Function: Creating a Perfect, Resilient Seal

The primary role of any gasket is to prevent leaks. However, industrial environments present significant challenges, such as microscopic imperfections in flange surfaces and immense operational pressures. PTFE is uniquely suited to overcome these issues.

Compensating for Surface Imperfections

PTFE's softness and high compression ratio are key advantages. This allows the gasket to conform and flow into the tiny cracks, tool marks, and deviations present on metal surfaces.

This creates an exceptionally tight seal by embedding into fine cracks, effectively blocking potential leak paths that a more rigid material would miss.

Forming a Watertight and Gas-Tight Barrier

In processes like coupled pump-to-tank transfers, a single leak can compromise the entire operation. PTFE gaskets provide a definitive barrier for both liquids and gases.

Their ability to form a perfect seal ensures that the product being transferred stays within the system, maximizing output and preventing environmental contamination.

Why PTFE Excels in Demanding Environments

The chemical and petrochemical industries are defined by extreme conditions that would cause most sealing materials to fail. PTFE’s molecular structure gives it a unique combination of properties that make it the material of choice.

Unmatched Chemical Resistance

PTFE is virtually inert to most chemicals, including highly corrosive acids and aggressive fluids found in processing plants.

This resistance prevents the gasket from degrading, swelling, or failing when exposed to harsh media, ensuring a long-lasting and reliable seal. It only shows vulnerability to a few substances, like certain alkali metals and fluorine compounds.

Extreme Temperature Tolerance

Petrochemical processes often involve radical temperature swings, from cryogenic lows to high-temperature refining.

PTFE maintains its integrity and sealing capability across this wide thermal range, providing stable and predictable performance where other materials would become brittle or melt.

Non-Corrosive and Inert Nature

Because PTFE does not corrode or react with the fluids it contains, it protects the purity of the process media. This also means the gasket itself won't degrade and shed particles that could contaminate or damage downstream equipment.

Understanding the Long-Term Efficiency Gains

Choosing a gasket material goes beyond its initial sealing capability. The long-term impact on maintenance, safety, and operational uptime is where the true efficiency gains are realized.

Reducing Downtime and Maintenance

PTFE gaskets have an exceptionally long product life, even under continuous and demanding use.

This durability directly translates to lower maintenance costs and, more importantly, increased operational uptime. A system that doesn't need to be shut down for frequent gasket replacement is inherently more efficient and profitable.

Enhancing Safety and Reliability

A failed seal in a petrochemical plant can have catastrophic consequences. Leaks of flammable or toxic materials pose a severe safety risk.

By providing a highly reliable seal, PTFE gaskets are a critical component of plant safety. This reliability prevents costly shutdowns, cleanup operations, and potential regulatory fines.

Versatility Across Applications

The same properties that make PTFE ideal for sealing pipe flanges also make it effective in valves, fittings, and even as electrical insulation in equipment like transformers and generators. Its versatility simplifies material specification and inventory across a facility.

Making the Right Choice for Your Goal

The decision to use PTFE should be aligned with the specific demands of your application.

- If your primary focus is handling highly corrosive media: PTFE's chemical inertness is its most critical feature, ensuring seal integrity where other materials would dissolve or degrade.

- If your primary focus is processes with extreme temperature fluctuations: PTFE's wide operating temperature range ensures a stable and reliable seal from cryogenic conditions to high heat.

- If your primary focus is maximizing long-term operational efficiency: The durability and long life of PTFE gaskets reduce maintenance cycles and costly downtime, delivering the best overall value.

Ultimately, specifying PTFE gaskets is an investment in the uninterrupted and safe performance of your most critical systems.

Summary Table:

| Key Benefit | How PTFE Delivers | Impact on Operation |

|---|---|---|

| Leak Prevention | Conforms to surface imperfections, forming a perfect barrier for liquids and gases. | Prevents product loss and environmental contamination. |

| Chemical Resistance | Virtually inert to most corrosive acids and aggressive fluids. | Ensures long-lasting seal integrity and protects process media purity. |

| Temperature Tolerance | Maintains performance from cryogenic conditions to high heat. | Provides reliable operation across wide thermal swings. |

| Durability & Long Life | Exceptional resistance to degradation under continuous use. | Reduces maintenance cycles and costly downtime, maximizing uptime. |

Maximize the efficiency and safety of your chemical or petrochemical systems with precision-engineered PTFE components from KINTEK.

Whether you need standard PTFE gaskets or custom-fabricated seals, liners, or labware for the semiconductor, medical, laboratory, or industrial sectors, KINTEK delivers. We combine precision production with the flexibility to support your needs from prototypes to high-volume orders.

Contact KINTEK today to discuss your specific application requirements and discover how our PTFE solutions can enhance your operational reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials