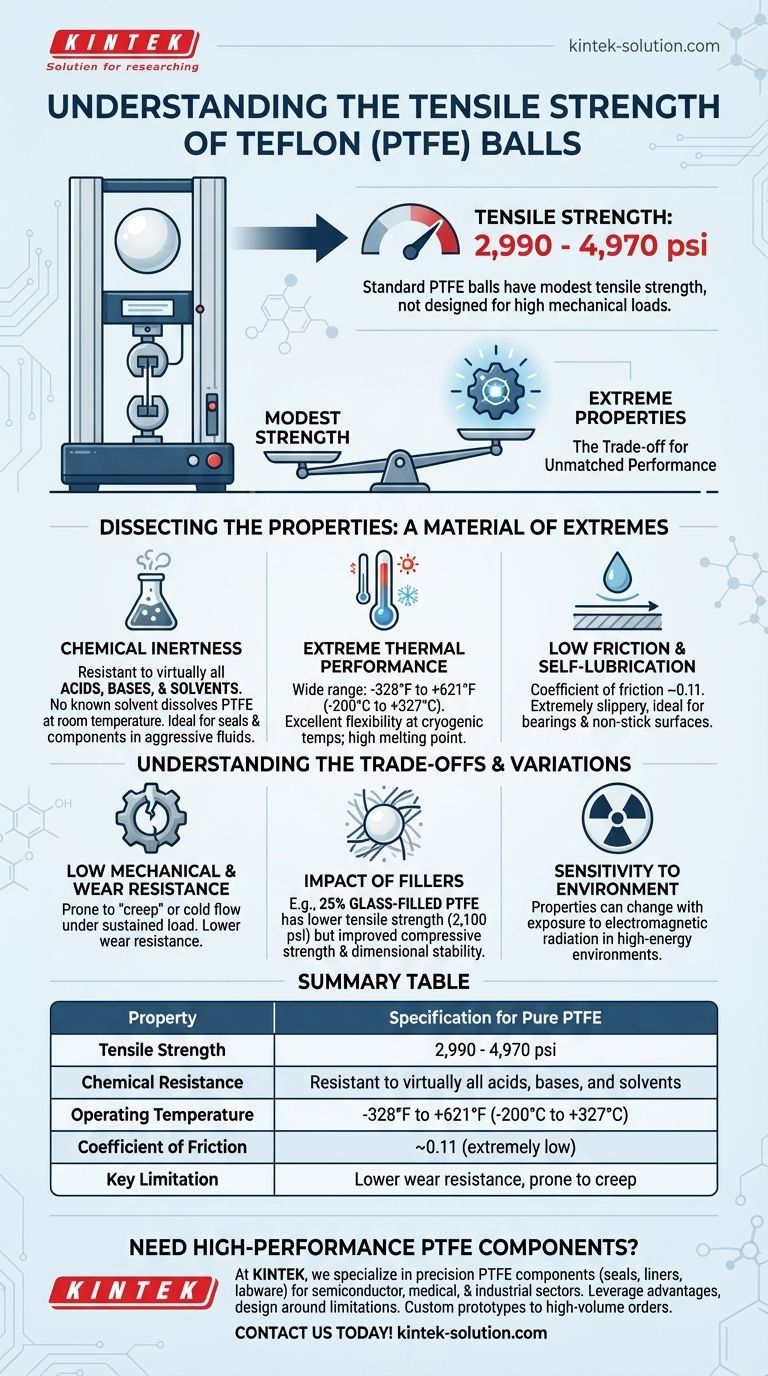

The tensile strength of standard Teflon (PTFE) balls typically falls within the range of 2,990 to 4,970 psi. This value, however, is only one part of the story, as the true value of Teflon lies not in its mechanical strength but in its unique combination of other extreme properties.

Understanding Teflon requires a shift in perspective. Its relatively low tensile strength is a known trade-off for gaining world-class chemical inertness, an extremely wide operating temperature range, and a remarkably low coefficient of friction.

Dissecting the Properties of Teflon (PTFE)

To properly evaluate Teflon for any application, you must look beyond a single metric and consider its full performance profile. It is a material of extremes, excelling in areas where most other polymers fail.

The Tensile Strength Specification

The tensile strength of pure, unfilled Teflon balls is most reliably cited in the 2,990 to 4,970 psi range. This measures the maximum stress the material can withstand while being pulled or stretched before breaking.

Compared to many engineering plastics, this value is relatively modest. It signifies that Teflon is not intended for high-load, structural applications.

Its True Superpower: Chemical Inertness

Teflon's defining characteristic is its unparalleled resistance to chemicals. It is resistant to virtually all known industrial acids, bases, and caustics.

There is no known solvent that can dissolve PTFE at room temperature, making it the material of choice for seals, valves, and components handling aggressive or highly pure fluids.

Extreme Thermal Performance

Teflon operates across an exceptionally wide temperature range. It has a high melting point of 621°F (327°C) and retains excellent flexibility at cryogenic temperatures as low as -328°F (-200°C).

This makes it suitable for applications that experience extreme environmental or process temperature swings.

Low Friction and Self-Lubrication

With a very low coefficient of friction (around 0.11), Teflon is one of the "slipperiest" solid materials known. This property makes it ideal for low-friction bearings, seals, and non-stick surfaces where self-lubrication is critical.

Understanding the Trade-offs and Variations

Choosing Teflon means accepting its limitations. Its weaknesses are just as important to understand as its strengths.

Low Mechanical and Wear Resistance

The trade-off for Teflon's flexibility and chemical resilience is its relatively poor mechanical performance. Beyond its modest tensile strength, it has lower wear resistance compared to other plastics.

It can be prone to "creep" or cold flow, where the material deforms permanently under a sustained load.

The Impact of Fillers

To mitigate some of its mechanical weaknesses, Teflon is often mixed with fillers like glass. However, this changes its properties significantly.

For example, a 25% glass-filled Teflon has a much lower tensile strength of 2,100 psi. While this might seem like a downgrade, the filler improves other characteristics like compressive strength and dimensional stability, creating a different material for a different purpose.

Sensitivity to Environment

While chemically inert, pure PTFE's properties can be altered by exposure to electromagnetic radiation. This is a niche but critical consideration for applications in certain high-energy environments.

Making the Right Choice for Your Application

Selecting the right material requires matching its properties to your primary goal.

- If your primary focus is sealing aggressive chemicals or ensuring low-friction movement: Teflon is an exceptional choice, provided the mechanical loads are low and well-understood.

- If your primary focus is bearing a high structural or tensile load: You should evaluate other engineering plastics or metals, as Teflon's low strength is a significant design constraint.

- If your primary focus is a balance of chemical resistance and improved hardness: Consider a filled grade of PTFE, but be prepared for a trade-off in other properties like tensile strength.

Ultimately, successfully deploying Teflon balls hinges on designing for their strengths while respecting their mechanical limitations.

Summary Table:

| Property | Specification for Pure PTFE |

|---|---|

| Tensile Strength | 2,990 - 4,970 psi |

| Chemical Resistance | Resistant to virtually all acids, bases, and solvents |

| Operating Temperature Range | -328°F to +621°F (-200°C to +327°C) |

| Coefficient of Friction | ~0.11 (extremely low, self-lubricating) |

| Key Limitation | Lower wear resistance and prone to creep under sustained load |

Need High-Performance PTFE Components?

Understanding the precise balance of properties in PTFE is key to your project's success. At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We help you leverage Teflon's unique advantages while designing around its limitations. Whether you need a custom prototype or a high-volume order, our expertise ensures you get the right part for your exact requirements.

Contact us today to discuss your application and get a quote!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What precautions should be taken when installing PTFE O-rings? Avoid Permanent Damage and Seal Failure

- How can counter rotation failure be avoided in rotary seals? Prevent Costly Seal Failure and Downtime

- What additional advantages does expanded PTFE offer? Superior Sealing, Stability & Purity for Critical Applications

- What industries commonly use PTFE bellows and diaphragms, and why? Ensure Purity & Chemical Resistance

- What key properties make PTFE an ideal sealing material for extreme temperatures? Unmatched Thermal Stability from -270°C to 260°C

- What aerospace applications utilize Teflon plastic sheets? Critical Components for Extreme Environments

- What are the aerospace applications of precision-machined PTFE parts? Achieve Peak Performance in Harsh Environments

- What temperature range can PTFE impellers withstand? Operate from -200°C to 260°C