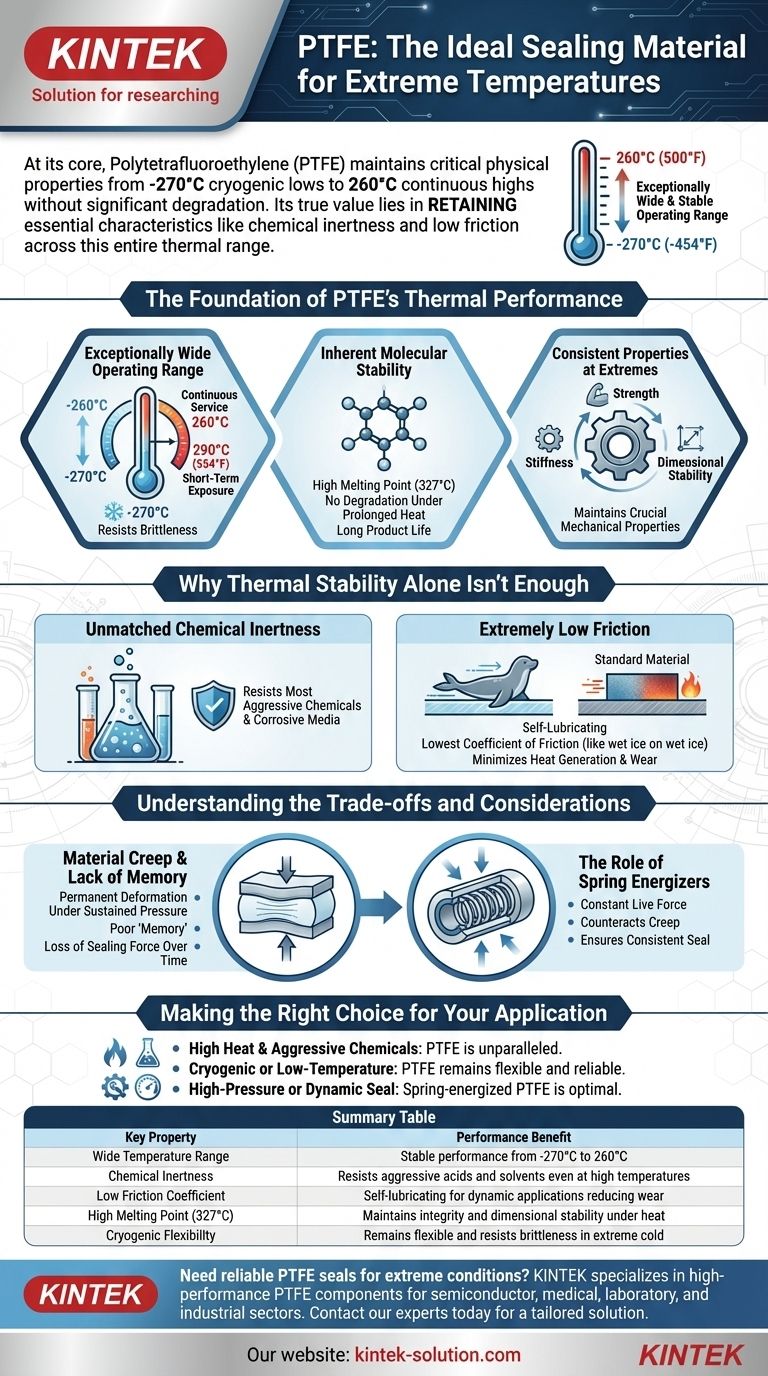

At its core, Polytetrafluoroethylene (PTFE) is an ideal sealing material for extreme temperatures due to its exceptionally wide and stable operating range. It maintains its critical physical properties from cryogenic lows of -270°C (-454°F) up to continuous high temperatures of 260°C (500°F) without significant degradation, a feat few other polymers can achieve.

The true value of PTFE is not just its ability to survive extreme temperatures, but its capacity to retain its other essential sealing characteristics—like chemical inertness and low friction—across that entire thermal range, ensuring reliable and consistent performance where other materials would fail.

The Foundation of PTFE's Thermal Performance

To understand why PTFE is so effective, we must look at how its properties work in concert under thermal stress. It isn't one single attribute but a combination of factors that makes it a superior choice for demanding environments.

Exceptionally Wide Operating Range

PTFE functions reliably across a vast temperature spectrum. It can withstand continuous service temperatures up to 260°C (500°F) and short-term exposure to 290°C (554°F).

On the other end, it performs exceptionally well in cryogenic conditions as low as -270°C (-454°F), resisting the brittleness that causes many materials to fracture in extreme cold.

Inherent Molecular Stability

PTFE's thermal resilience comes from its molecular structure. It has a very high melting point of 327°C (621°F), meaning it does not become soft or lose its integrity at temperatures common in industrial applications.

This intrinsic stability ensures the material does not degrade or break down when exposed to prolonged heat, contributing to a long product life.

Consistent Properties at Temperature Extremes

Simply surviving a temperature is not enough for a seal. PTFE excels because it maintains its crucial mechanical properties like stiffness, strength, and dimensional stability at both high and low temperatures.

This consistency ensures the seal continues to perform its function effectively, regardless of thermal fluctuations in the operating environment.

Why Thermal Stability Alone Isn't Enough

A material can be heat-resistant yet still be a poor seal. PTFE's value comes from its other world-class properties that are maintained even when the temperature is pushed to its limits.

Unmatched Chemical Inertness

High temperatures often accelerate chemical reactions, causing other sealing materials to corrode or degrade. PTFE is almost completely chemically inert, resisting even the most aggressive acids, solvents, and bases.

This makes it an indispensable choice for applications involving both extreme heat and corrosive media.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This self-lubricating or non-stick quality is vital in dynamic sealing applications.

By minimizing friction, the seal generates less heat on its own and experiences significantly less wear, extending its operational life, especially in high-speed or high-pressure systems.

Understanding the Trade-offs and Considerations

No material is perfect, and its limitations must be understood to be engineered around. Objectivity requires acknowledging where standard PTFE may need reinforcement.

Material Creep and a Lack of 'Memory'

A notable characteristic of PTFE is its tendency to creep, or deform permanently under sustained pressure. Unlike an elastomer like rubber, it has poor "memory" and will not spring back to its original shape after being compressed.

This allows the seal to conform tightly to a mating surface, but it can also lead to a loss of sealing force over time if not properly managed.

The Role of Spring Energizers

To counteract material creep, PTFE seals are often designed with a spring energizer. This internal spring, typically made of metal, provides a constant, live force against the sealing surfaces.

The energizer ensures that even if the PTFE material relaxes or creeps, a consistent and reliable seal is maintained throughout the life of the component.

Making the Right Choice for Your Application

Selecting the right seal requires matching the material's properties to your specific operational goal.

- If your primary focus is high heat and aggressive chemicals: PTFE is an unparalleled choice due to its unique combination of extreme thermal stability and near-total chemical inertness.

- If your primary focus is cryogenic or low-temperature sealing: PTFE's ability to remain flexible and avoid becoming brittle at extreme lows makes it one of the most reliable options available.

- If your primary focus is a high-pressure or dynamic seal: A spring-energized PTFE seal is the optimal solution, as it leverages PTFE's low friction while compensating for its natural tendency to creep.

Ultimately, PTFE's unique profile makes it the default engineering solution for sealing applications where performance cannot be compromised by thermal extremes.

Summary Table:

| Key Property | Performance Benefit |

|---|---|

| Wide Temperature Range | Stable performance from -270°C to 260°C |

| Chemical Inertness | Resists aggressive acids and solvents even at high temperatures |

| Low Friction Coefficient | Self-lubricating for dynamic applications, reducing wear |

| High Melting Point (327°C) | Maintains integrity and dimensional stability under heat |

| Cryogenic Flexibility | Remains flexible and resists brittleness in extreme cold |

Need reliable PTFE seals for extreme conditions? KINTEK specializes in manufacturing high-performance PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, ensure you get seals that maintain critical properties under thermal stress. Contact our experts today to discuss your specific application requirements and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What temperature range can PTFE O-rings withstand? Unlock Extreme Thermal Performance from -200°C to 260°C

- What design considerations are important for PTFE lip seals in extreme temperatures? | Material, Geometry & Energizer

- What temperature range can PTFE gaskets and sheets withstand? A Guide from -200°C to +260°C

- How do PTFE lined and hard seal butterfly valves differ in sealing performance? Unlock the Trade-Off for Your Application

- Why is filled-PTFE often chosen for rotary shaft seal lips? For Unmatched Performance in Extreme Conditions

- What industries commonly use Teflon machined parts and why? Achieve Unmatched Performance in Demanding Environments

- What are the common applications of Teflon sheets in the food industry? Boost Efficiency & Hygiene

- What are the advantages and disadvantages of composite PTFE diaphragms? Balancing Chemical Resistance and Flexibility