In the demanding world of aerospace engineering, precision-machined Polytetrafluoroethylene (PTFE) parts are fundamental components in critical systems. They are most commonly used for seals, gaskets, bearings, and liners within aircraft engines, fuel systems, and hydraulic systems due to their exceptionally low friction, high thermal stability, and resistance to corrosive fluids.

The true value of precision-machined PTFE in aerospace isn't just its versatility, but its unique combination of extreme temperature resistance, chemical inertness, and an exceptionally low coefficient of friction. This triad of properties allows it to solve critical engineering challenges related to wear, sealing, and insulation where other materials would fail.

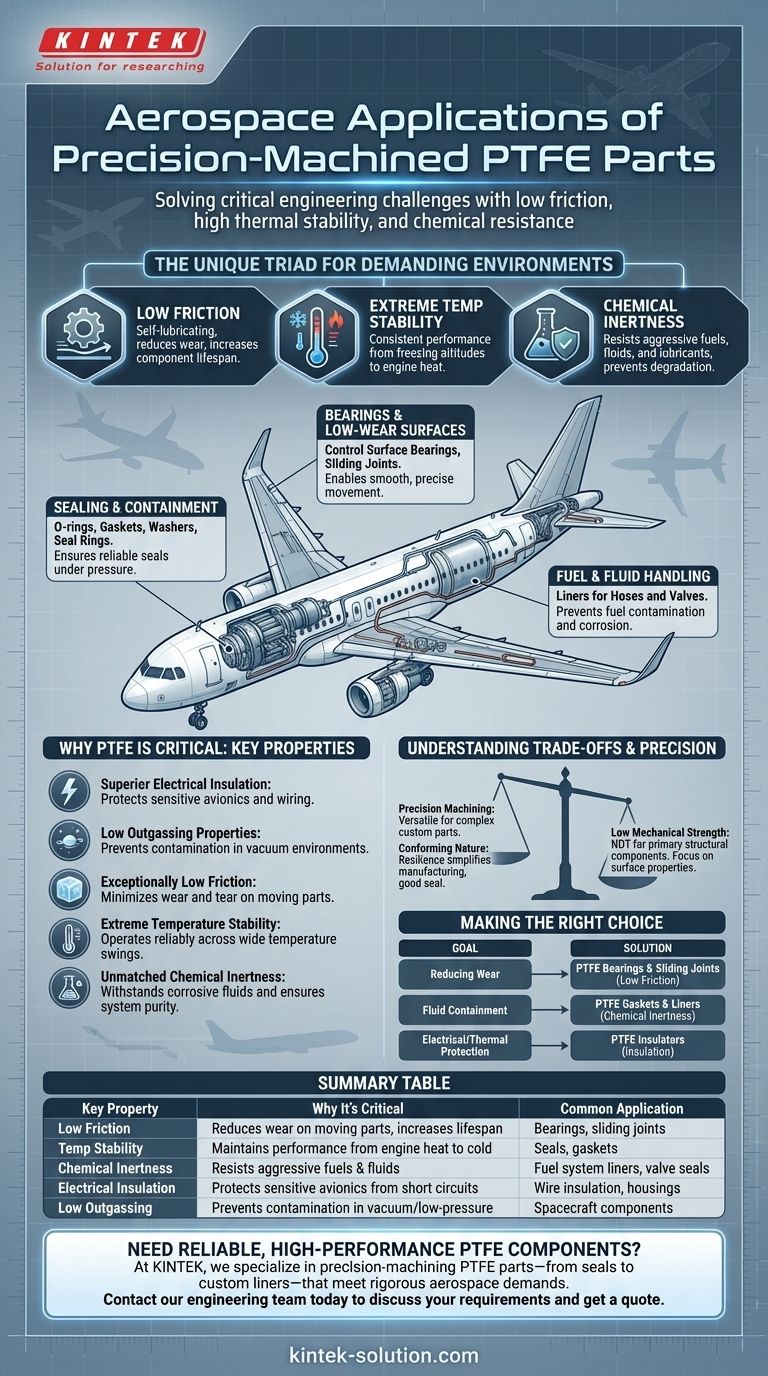

Why PTFE is a Critical Material in Aerospace

The selection of any material for aerospace applications is a rigorous process. PTFE is consistently chosen because its intrinsic properties solve multiple problems simultaneously, enhancing both safety and performance.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This self-lubricating property is critical for reducing wear and tear on moving parts, which in turn increases component lifespan and reduces maintenance requirements.

Extreme Temperature Stability

Aerospace components operate in environments with dramatic temperature fluctuations, from the intense heat of an engine to the freezing cold of high altitudes. PTFE maintains its integrity and performance characteristics across a very wide thermal range, ensuring consistent and reliable operation.

Unmatched Chemical Inertness

PTFE is virtually inert and does not react with the vast majority of chemicals. This makes it the ideal material for components that come into direct contact with aggressive aviation fuels, hydraulic fluids, and lubricants, preventing degradation and ensuring system purity.

Superior Electrical Insulation

As a fantastic electrical insulator, PTFE is used to protect sensitive wiring and electronic components. This property is crucial for preventing short circuits and interference in the complex avionics systems of modern aircraft.

Low Outgassing Properties

In the vacuum of space or the low-pressure environment of high altitudes, some materials can release trapped gasses in a process called outgassing. PTFE has very low outgassing characteristics, which is essential for preventing contamination of sensitive optical and electronic equipment.

Key Aerospace Applications in Detail

The unique properties of PTFE translate directly into its use in specific, high-stakes applications throughout an aircraft.

Sealing and Containment

Parts like O-rings, gaskets, washers, and seal rings made from PTFE are ubiquitous in aerospace. They are used to create reliable seals in fuel and hydraulic systems, preventing leaks under high pressure and extreme temperatures.

Bearings and Low-Wear Surfaces

PTFE is machined into control surface bearings and sliding joints. These components allow control surfaces like ailerons and rudders to move smoothly and with minimal resistance, ensuring the pilot has precise control of the aircraft without the need for frequent lubrication.

Fuel and Fluid Handling

Within fuel systems, PTFE serves as liners for hoses and valves. Its chemical inertness ensures that the fuel is not contaminated and that the components themselves do not corrode over time, maintaining the integrity of the entire system.

Understanding the Trade-offs

While highly capable, PTFE is not a universal solution. Understanding its limitations is key to its successful application.

The Role of Precision Machining

PTFE is a relatively soft material that is easily machined using standard CNC equipment. This makes it versatile for creating complex custom parts. The "precision" aspect is vital for ensuring parts meet the exact specifications required for a perfect seal or fit.

The "Conforming" Nature of PTFE

One of PTFE's advantages is its resilience, which allows it to deform slightly and conform to mating surfaces. This often means that ultra-tight machining tolerances are not as critical as they would be for a rigid metal, which can simplify manufacturing.

Limitations in Structural Integrity

The primary drawback of PTFE is its low mechanical strength and resistance to creep under load. It should never be used for primary structural components. Its value is in its surface properties—friction, chemical resistance, and insulation—not its ability to bear significant mechanical loads.

Making the Right Choice for Your Goal

Selecting PTFE is a decision based on solving a specific engineering problem. Your primary goal will determine if it's the right fit.

- If your primary focus is reducing wear in moving parts: PTFE's exceptionally low friction makes it the definitive choice for bearings, sliding joints, and seal rings.

- If your primary focus is ensuring fluid containment: Its chemical inertness and resilience are ideal for gaskets, seals, and liners in aggressive fuel and hydraulic systems.

- If your primary focus is electrical or thermal protection: PTFE's insulating properties provide a reliable barrier for sensitive wiring and electronic components against heat and electrical interference.

Ultimately, leveraging precision-machined PTFE allows aerospace engineers to build more reliable, efficient, and durable systems that can withstand the harshest operating conditions.

Summary Table:

| Key Property | Why It's Critical for Aerospace | Common Application |

|---|---|---|

| Low Friction | Reduces wear on moving parts, increases lifespan | Bearings, sliding joints |

| Temperature Stability | Maintains performance from engine heat to high-altitude cold | Seals, gaskets |

| Chemical Inertness | Resists aggressive aviation fuels and hydraulic fluids | Fuel system liners, valve seals |

| Electrical Insulation | Protects sensitive avionics from short circuits | Wire insulation, component housings |

| Low Outgassing | Prevents contamination in vacuum/low-pressure environments | Spacecraft components |

Need reliable, high-performance PTFE components for your aerospace project?

At KINTEK, we specialize in precision-machining PTFE parts—from seals and gaskets to custom liners and labware—that meet the rigorous demands of the aerospace, medical, and semiconductor industries. Our expertise in custom fabrication ensures your prototypes and high-volume orders are built to exact specifications for superior performance and durability.

Contact our engineering team today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments