In aerospace, Teflon (PTFE) plastic sheets are primarily utilized for high-performance seals, gaskets, electrical insulation, and low-friction bearings. These components are critical for the reliable operation of engines, fuel systems, landing gear, and spacecraft, where materials must perform flawlessly under extreme environmental stress.

The core reason for Teflon's widespread use in aerospace is not a single feature, but its unique combination of properties. Its ability to simultaneously resist extreme temperatures, withstand corrosive chemicals, and provide a near-frictionless surface makes it an indispensable problem-solver in applications where failure is not an option.

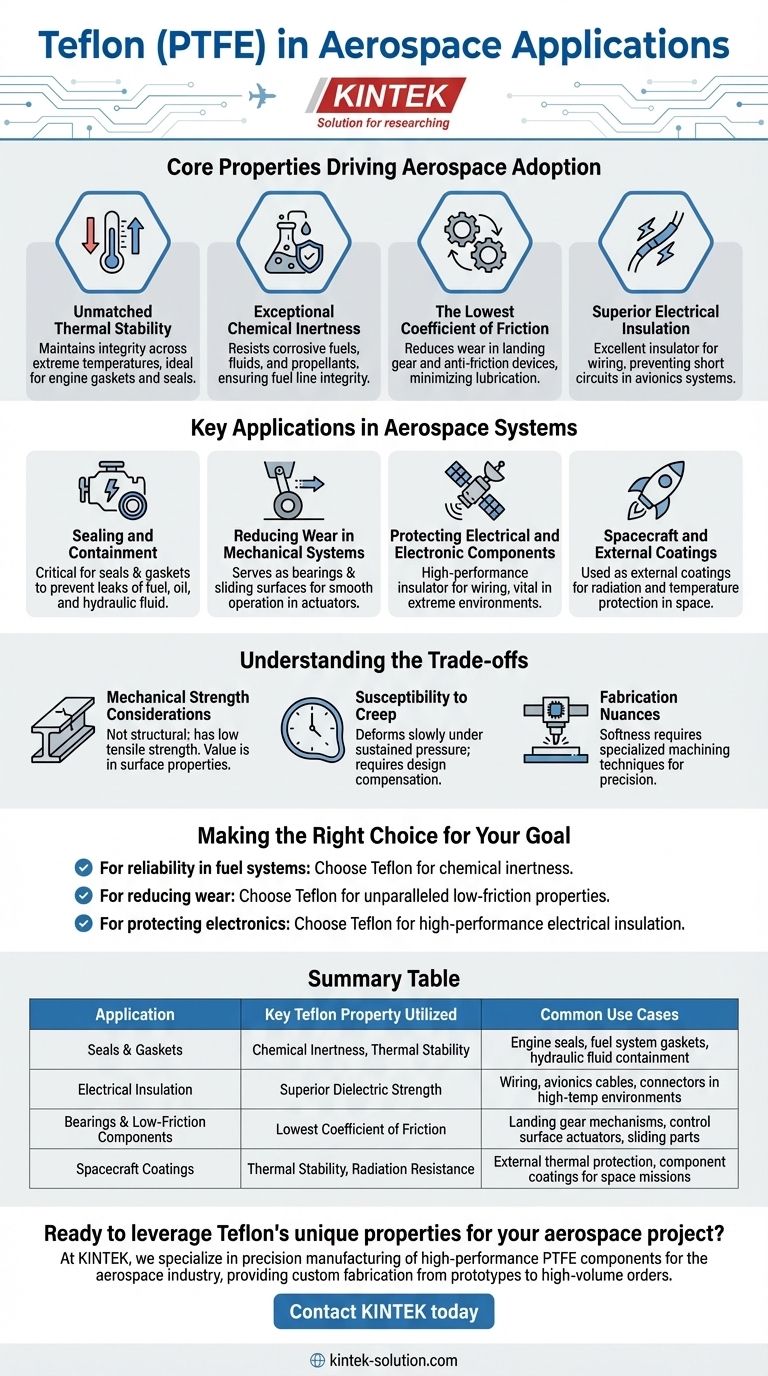

The Core Properties Driving Aerospace Adoption

The harsh conditions of flight and space—from cryogenic cold to intense engine heat, and from corrosive fuels to the vacuum of space—demand materials with an exceptional performance profile. Teflon meets these demands through several key characteristics.

Unmatched Thermal Stability

Teflon maintains its integrity across an incredibly wide temperature range. This makes it ideal for components like engine gaskets and seals that are exposed to both the extreme cold of high altitudes and the intense heat of combustion.

Exceptional Chemical Inertness

Aerospace systems rely on aggressive fuels, hydraulic fluids, and propellants. Teflon is virtually inert, meaning it will not react with or degrade upon contact with these corrosive substances, ensuring the integrity of fuel lines and storage tanks.

The Lowest Coefficient of Friction

Known as one of the slickest materials in existence, Teflon is used to create anti-friction devices, bearings, and coatings. In applications like landing gear mechanisms, this property reduces wear and tear, minimizes the need for lubrication, and ensures smooth, reliable operation.

Superior Electrical Insulation

Modern aircraft and spacecraft are packed with complex electronics. Teflon is an excellent electrical insulator, used to coat wires and cables. This prevents short circuits and ensures the integrity of avionic systems, even when subjected to significant temperature fluctuations.

Key Applications in Aerospace Systems

These fundamental properties translate directly into critical components that ensure safety and mission success. The material is typically machined from sheets or other stock forms into specific, high-value parts.

Sealing and Containment

The most common application is in seals and gaskets. Placed in engines and fuel systems, these parts prevent dangerous leaks of fuel, oil, and hydraulic fluid, which is essential for both safety and performance.

Reducing Wear in Mechanical Systems

In landing gear, control surfaces, and other moving assemblies, Teflon serves as a bearing or sliding surface. Its low-friction nature allows parts to move smoothly against each other without seizing or premature wear.

Protecting Electrical and Electronic Components

Teflon is used as a high-performance insulator for wiring. This is particularly important for cables that must run near hot engine components or be exposed to the vacuum of space, where other materials would quickly degrade.

Spacecraft and External Coatings

On a broader scale, Teflon and related fluoropolymers are used as coatings for spacecraft. These coatings help protect the craft from the harsh radiation and extreme temperature swings encountered outside of Earth's atmosphere.

Understanding the Trade-offs

While its properties are exceptional, Teflon is not a universal solution. A clear understanding of its limitations is essential for proper engineering design.

Mechanical Strength Considerations

Teflon is not a structural material. Compared to metals like aluminum or titanium, it has low tensile strength and should not be used for load-bearing applications. Its value is in its surface properties and resilience, not its strength.

Susceptibility to Creep

Under sustained pressure, especially at elevated temperatures, Teflon can slowly deform over time—a phenomenon known as "creep." Engineers must account for this in the design of components like seals to ensure they maintain their integrity over the life of the aircraft.

Fabrication Nuances

While it can be machined, Teflon's softness and malleability require specialized techniques. Improper handling can lead to dimensional inaccuracies, making precision manufacturing a critical factor for high-performance aerospace parts.

Making the Right Choice for Your Goal

Selecting the right material is about matching its properties to the specific challenge you need to solve.

- If your primary focus is reliability in fuel and hydraulic systems: Teflon's chemical inertness makes it the definitive choice for seals, gaskets, and liners that must handle corrosive fluids.

- If your primary focus is reducing wear in moving parts: Its unparalleled low-friction properties are ideal for bearings and sliding surfaces in actuators and landing gear.

- If your primary focus is protecting sensitive electronics: Its high-performance electrical insulation is critical for wiring in environments with extreme temperatures.

By understanding its unique blend of resilience and performance, engineers can leverage Teflon to build safer, more reliable, and longer-lasting aerospace systems.

Summary Table:

| Application | Key Teflon Property Utilized | Common Use Cases |

|---|---|---|

| Seals & Gaskets | Chemical Inertness, Thermal Stability | Engine seals, fuel system gaskets, hydraulic fluid containment |

| Electrical Insulation | Superior Dielectric Strength | Wiring, avionics cables, connectors in high-temp environments |

| Bearings & Low-Friction Components | Lowest Coefficient of Friction | Landing gear mechanisms, control surface actuators, sliding parts |

| Spacecraft Coatings | Thermal Stability, Radiation Resistance | External thermal protection, component coatings for space missions |

Ready to leverage Teflon's unique properties for your aerospace project?

At KINTEK, we specialize in precision manufacturing of high-performance PTFE components for the aerospace, semiconductor, medical, and laboratory industries. We understand the critical demands of aerospace applications and provide custom fabrication from prototypes to high-volume orders.

Our expertise ensures your components meet the exacting standards required for extreme environments. Let us help you build safer, more reliable systems.

Contact KINTEK today to discuss your specific requirements and get a quote for your custom PTFE solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How should thin-wall PTFE components be clamped during machining? Prevent Deformation with the Right Fixtures

- Can PTFE lined check valves handle high-pressure water systems? Yes, up to 232 PSI.

- How are PTFE lip seals used in the aerospace industry? Ensure Reliability in Extreme Conditions

- What makes PTFE expansion bellows suitable for aerospace applications? Unmatched Reliability in Extreme Environments

- In what applications are PTFE-lined bearings particularly beneficial? For Maintenance-Free Performance in Harsh Environments

- How are PTFE bushes manufactured to ensure quality? A Guide to Precision and Reliability

- What material are typical rotary seals made of and what are their limitations? Choose the Right Seal for Your Application

- What are the material highlights of PTFE? Unlock Extreme Chemical and Thermal Resistance