In short, PTFE-lined bearings are particularly beneficial in applications that demand maintenance-free, low-friction performance, especially where conventional grease or oil lubrication is impractical, undesirable, or could lead to contamination. They excel in automotive components, industrial machinery, food processing, and medical devices.

The core value of a PTFE-lined bearing is not just its low friction, but its ability to deliver that performance reliably over a long life without external lubrication, even in chemically aggressive or sanitary environments.

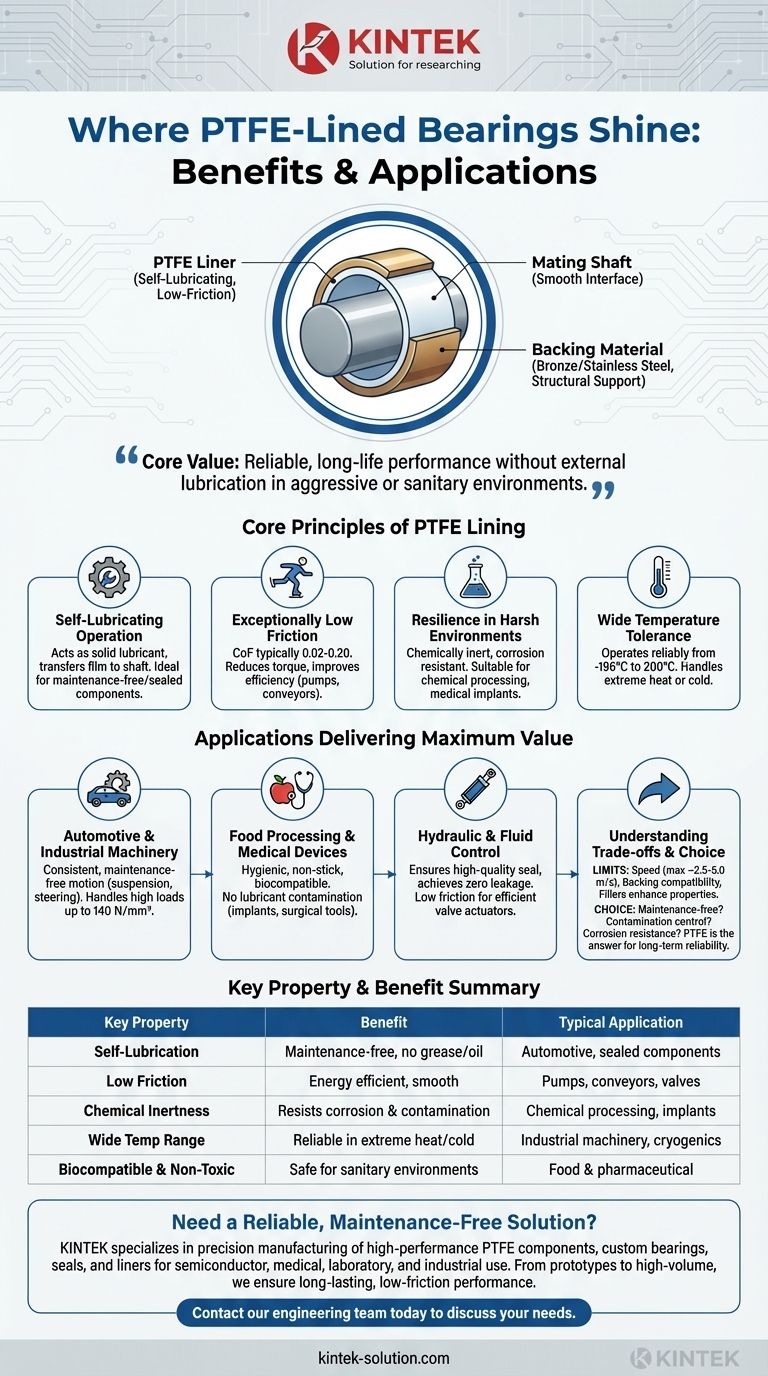

The Core Principles of a PTFE Lining

To understand where these bearings shine, you must first understand the fundamental properties that a Polytetrafluoroethylene (PTFE) liner provides.

Self-Lubricating Operation

The primary benefit is self-lubrication. The PTFE layer acts as a solid lubricant that transfers a thin film to the mating shaft during initial operation.

This eliminates the need for grease or oil, making these bearings ideal for sealed-for-life components or machinery in locations where regular maintenance is difficult.

Exceptionally Low Friction

PTFE boasts an extremely low coefficient of friction, typically between 0.02 and 0.20 in dry operation.

This property reduces startup torque and running energy consumption, resulting in smoother, more efficient mechanical operation for devices like pumps and conveyors.

Resilience in Harsh Environments

PTFE is chemically inert, giving it excellent resistance to corrosion and chemical attack from a wide range of substances.

This makes PTFE-lined components suitable for chemical processing, while its biocompatibility makes it a premier choice for medical implants, such as heart valves, where it resists bodily fluids.

Wide Temperature Tolerance

The material maintains its integrity across a broad temperature spectrum, with typical operating ranges from -196°C to 200°C.

This stability allows PTFE-lined bearings and valves to function reliably in applications involving extreme heat or cold without a significant drop in performance.

Where These Properties Deliver Maximum Value

Certain industries and applications are uniquely suited to capitalize on the advantages of PTFE.

Automotive and Industrial Machinery

In automotive systems like suspension struts and steering columns, PTFE bearings provide consistent, smooth motion without requiring maintenance over the vehicle's lifespan.

For industrial conveyors and pumps, their ability to handle significant dynamic loads (up to 140 N/mm²) while remaining self-lubricated reduces downtime and operational costs.

Food Processing and Medical Devices

The non-stick, non-toxic, and inert nature of PTFE is critical in environments where hygiene is paramount. There is no risk of lubricant contaminating the product.

In medical devices, this biocompatibility and resistance to sterilization processes make it an indispensable material for implants and surgical tools.

Hydraulic and Fluid Control

In components like hydraulic cylinders or butterfly valves, a PTFE lining ensures a high-quality seal, often achieving zero leakage.

Its low friction reduces the torque needed to operate the valve, allowing for smaller, more efficient actuators and smoother fluid control.

Understanding the Trade-offs

While highly effective, PTFE-lined bearings are not a universal solution. Objectivity requires acknowledging their operational limits.

Speed Limitations

PTFE-lined plain bearings have a maximum recommended sliding speed, typically around 2.5 m/s for dry operation and up to 5.0 m/s with lubrication.

For high-RPM rotational applications, traditional roller or ball bearings are often a more suitable choice.

The Importance of the Backing Material

The overall strength and corrosion resistance of the bearing assembly depend heavily on its backing material, which is commonly bronze or stainless steel.

Choosing the wrong backing can negate the benefits of the PTFE liner. For example, using a bronze-backed bearing in a highly corrosive environment is a poor design choice.

The Role of Fillers

Standard PTFE can be enhanced with fillers (such as glass fiber, carbon, or graphite) to improve specific properties like compressive strength, thermal conductivity, and wear resistance.

For demanding applications, specifying a "filled PTFE" may be necessary to meet performance requirements that standard PTFE cannot.

Making the Right Choice for Your Application

Your final decision should be guided by your primary engineering goal.

- If your primary focus is maintenance-free operation: PTFE is the ideal choice for sealed components or machinery in remote or inaccessible locations.

- If your primary focus is contamination control: The self-lubricating and inert properties of PTFE make it a definitive solution for food, medical, and pharmaceutical applications.

- If your primary focus is high-speed rotation: You must carefully evaluate PTFE's sliding speed limits and consider alternative bearing types if your application exceeds them.

- If your primary focus is corrosion resistance: A PTFE-lined bearing, especially one with a stainless steel backing, offers a robust defense against chemical attack.

Ultimately, selecting a PTFE-lined bearing is a strategic decision for achieving long-term reliability in environments where traditional lubrication is destined to fail.

Summary Table:

| Key Property | Benefit | Typical Application |

|---|---|---|

| Self-Lubrication | Maintenance-free, no grease/oil | Automotive suspension, sealed components |

| Low Friction (0.02-0.20) | Energy efficient, smooth operation | Pumps, conveyors, valves |

| Chemical Inertness | Resists corrosion & contamination | Chemical processing, medical implants |

| Wide Temp Range (-196°C to 200°C) | Reliable in extreme heat/cold | Industrial machinery, cryogenics |

| Biocompatible & Non-Toxic | Safe for sanitary environments | Food processing, pharmaceutical equipment |

Need a reliable, maintenance-free bearing solution for your demanding application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom bearings, seals, and liners. Our expertise ensures your components deliver long-lasting, low-friction performance in the harshest conditions—whether in semiconductor, medical, laboratory, or industrial settings.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your specific requirements.

Contact our engineering team today to discuss how our PTFE solutions can enhance your product's reliability and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry