Typically, rotary seals are made from soft elastomers like rubber or polyurethane. While these materials are well-suited for some sealing applications due to their flexibility, their inherent softness is also their primary limitation, making them prone to rapid wear in high-stress, dynamic operations.

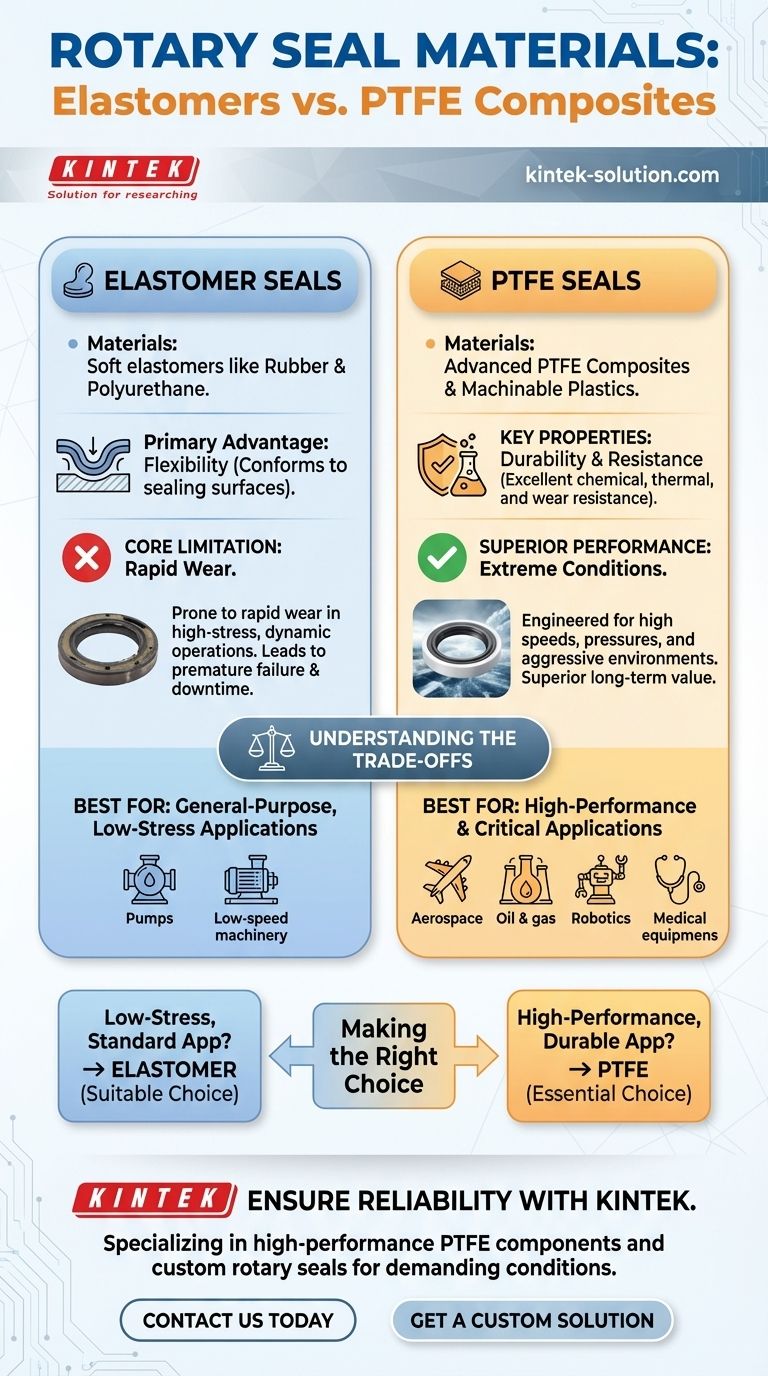

The choice of a rotary seal material is a direct trade-off between the demands of the application and the properties of the material. While traditional elastomers serve basic sealing needs, high-performance applications now depend on advanced materials like PTFE composites for superior durability and resilience under extreme conditions.

The Traditional Standard: Elastomer Seals

What Are Elastomers?

Elastomers are soft, resilient materials such as rubber and polyurethane. They are a common and long-standing choice for a wide range of general sealing applications.

The Primary Advantage

The main benefit of these materials is their flexibility. Their soft nature allows them to easily conform to sealing surfaces, creating an effective barrier in low-stress environments.

The Core Limitation: Rapid Wear

The Problem with Softness

The very softness that makes elastomers flexible is also their critical weakness. Under continuous rotational friction and pressure, these materials abrade and degrade quickly.

Failure in High-Stress Applications

In demanding or dynamic operations, this tendency to wear is accelerated. This leads to premature seal failure, leakage, and equipment downtime, making them unsuitable for high-performance machinery.

The High-Performance Alternative: PTFE Seals

A Shift to Advanced Materials

To overcome the limitations of elastomers, modern rotary seals are often made from a wide range of PTFE (Polytetrafluoroethylene) composites and other durable, machinable plastics.

Key Properties: Durability and Resistance

PTFE rotary seals provide excellent sealing performance due to their exceptional durability, chemical resistance, and ability to perform under extreme operating conditions. They are engineered to provide reliable service where traditional rubber O-rings or seals would fail.

Where PTFE Excels: Demanding Industries

These advanced seals are critical in a variety of sectors, including aerospace systems, oil and gas, and heavy-duty industrial machinery. They are also used extensively in applications where cleanliness is crucial, such as food processing, medical equipment, and pharmaceutical manufacturing.

Understanding the Trade-offs

Elastomers: For General-Purpose Sealing

Elastomer seals remain a viable option for simple, low-stress applications. In machinery where rotational speeds are low and pressures are moderate, their flexibility provides an adequate and functional seal.

PTFE: For Mission-Critical Performance

PTFE composite seals are the necessary choice for any application where failure is not an option. This includes equipment like screw compressors, pumps, gearboxes, and robotics, where high speeds, pressures, or aggressive chemicals are present.

Making the Right Choice for Your Goal

Selecting the correct material is fundamental to ensuring the reliability and longevity of your equipment.

- If your primary focus is a standard, low-stress application: An elastomer seal made of rubber or polyurethane is often a suitable and effective choice.

- If your primary focus is durability in a high-performance environment: A PTFE composite seal is essential to withstand high stress, extreme temperatures, or chemical exposure.

Ultimately, matching the seal material to the operational demands is the foundation of reliable performance.

Summary Table:

| Material | Best For | Key Limitation |

|---|---|---|

| Elastomers (Rubber, Polyurethane) | Low-stress, general-purpose applications | Prone to rapid wear in dynamic, high-stress operations |

| PTFE Composites | High-performance, extreme conditions (temperature, chemicals) | Higher initial cost, but superior long-term value |

Ensure your equipment's reliability with the right seal.

If your operations involve high speeds, extreme pressures, aggressive chemicals, or require ultimate cleanliness (like in semiconductor, medical, or pharmaceutical manufacturing), standard elastomer seals may not be enough.

KINTEK specializes in high-performance PTFE components, including custom rotary seals designed for durability and resilience in the most demanding conditions. We offer precision manufacturing from prototypes to high-volume orders.

Contact us today to discuss your specific requirements and let our experts help you eliminate downtime and prevent leaks.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts