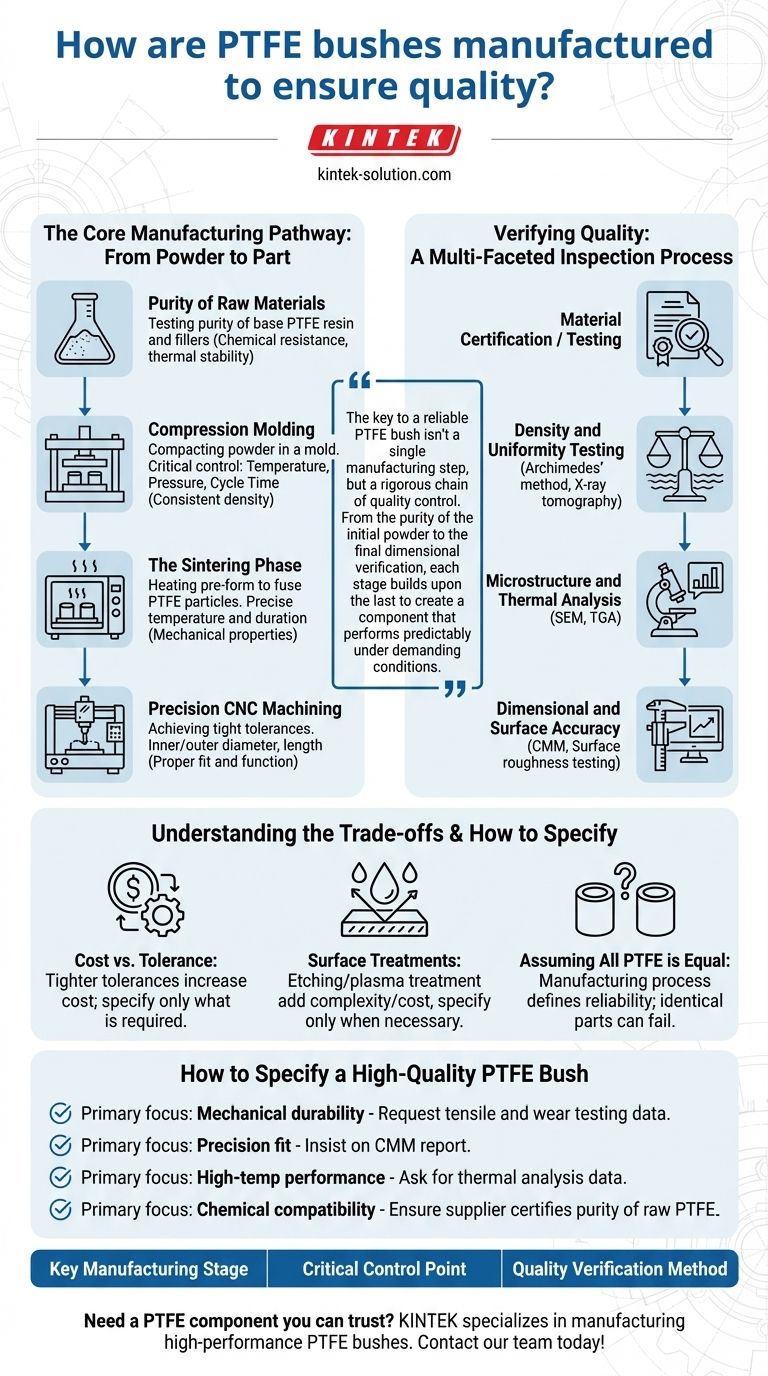

Manufacturing a high-quality PTFE bush is a multi-stage process rooted in meticulous control and verification. It begins with ensuring the purity of the raw material, followed by precise monitoring of temperature, pressure, and time during compression molding. The critical sintering phase, where PTFE particles are fused, is carefully controlled before advanced CNC machining achieves the final, precise dimensions required for performance.

The key to a reliable PTFE bush isn't a single manufacturing step, but a rigorous chain of quality control. From the purity of the initial powder to the final dimensional verification, each stage builds upon the last to create a component that performs predictably under demanding conditions.

The Core Manufacturing Pathway: From Powder to Part

Producing a PTFE bush that meets stringent engineering requirements involves a sequence of highly controlled stages. A failure or inconsistency at any point can compromise the integrity of the final component.

Purity of Raw Materials

The process begins before any shaping occurs. Reputable manufacturing requires testing the purity of the base PTFE resin and any fillers. This initial step ensures that the material's fundamental properties, such as chemical resistance and thermal stability, are not compromised by contaminants.

Compression Molding

The raw PTFE powder is placed into a mold and compacted under significant pressure. This "pre-form" is created while carefully monitoring and controlling three critical variables: temperature, pressure, and cycle time. This ensures the initial billet has a consistent density and is free from internal voids that could become failure points later.

The Sintering Phase

After molding, the pre-formed bush undergoes a process called sintering. It is heated in a precisely controlled oven to a temperature just below its melting point. This fuses the PTFE particles together into a solid, durable mass. The accuracy of the sintering temperature and duration is paramount for achieving the desired mechanical properties.

Precision CNC Machining

Once sintered, the rough PTFE bush is machined to its final dimensions. Advanced Computer Numerical Control (CNC) equipment is used to achieve the tight tolerances required for modern applications. This step determines the final accuracy of the bush's inner diameter, outer diameter, and length, ensuring a proper fit and function.

Verifying Quality: A Multi-Faceted Inspection Process

What separates a high-quality component from an unreliable one is the rigor of the post-production testing. Visual inspection is not enough; empirical data is required to validate the manufacturing process.

Density and Uniformity Testing

Techniques like the Archimedes’ method or X-ray tomography are used to measure the bush's density. This confirms that the molding and sintering processes were successful and that there are no hidden internal voids, which could lead to premature failure under load.

Mechanical Strength and Durability

To ensure the bush can withstand operational stresses, it undergoes a battery of mechanical tests. Tensile, bend, and wear testing provide quantitative data on the material's strength, flexibility, and resistance to abrasion, verifying its suitability for its intended application.

Microstructure and Thermal Analysis

For the most demanding applications, advanced analysis provides deeper insights. Scanning Electron Microscopy (SEM) can be used to analyze the microstructure, while Thermogravimetric Analysis (TGA) confirms the part's thermal stability and performance at elevated temperatures.

Dimensional and Surface Accuracy

Finally, the bush's physical dimensions and surface are verified. A Coordinate Measuring Machine (CMM) confirms that all geometric tolerances have been met with extreme precision. Surface roughness testing ensures the finish is appropriate for its mating components, which is critical for low-friction performance.

Understanding the Trade-offs

Specifying a PTFE bush requires balancing performance requirements with practical constraints. Understanding the inherent trade-offs is key to making an effective and economical choice.

Cost vs. Tolerance

Extremely tight dimensional tolerances require more advanced machining and more intensive quality control, which directly increases the cost of the component. It is crucial to specify only the level of precision that the application truly requires to avoid unnecessary expense.

The Impact of Surface Treatments

In some cases, a PTFE bush may require enhanced properties like better adhesion for bonding. Post-manufacturing surface treatments like etching or plasma treatment can achieve this, but they add complexity and cost to the process. These should only be specified when necessary.

Assuming All PTFE is Equal

A common pitfall is assuming that any part made of PTFE will perform the same. As outlined above, the manufacturing process and quality control regimen are what truly define the component's reliability, durability, and performance under pressure. A visually identical part can fail if it harbors internal voids or was improperly sintered.

How to Specify a High-Quality PTFE Bush

Your final specification should reflect the most critical aspects of your application. Use your requirements to guide your discussion with suppliers.

- If your primary focus is mechanical durability: Request data from tensile and wear testing to ensure the bush can handle the expected loads.

- If your primary focus is precision fit and assembly: Insist on a CMM report to verify that all critical dimensions meet your specified tolerances.

- If your primary focus is high-temperature performance: Ask for thermal analysis data to confirm the material's stability in your operating environment.

- If your primary focus is chemical compatibility: Ensure the supplier can certify the purity of the raw PTFE resin used in production.

Understanding these pillars of manufacturing and quality control empowers you to specify and source PTFE components with confidence.

Summary Table:

| Key Manufacturing Stage | Critical Control Point | Quality Verification Method |

|---|---|---|

| Raw Material Selection | Purity of PTFE Resin | Material Certification / Testing |

| Compression Molding | Temperature, Pressure, Time | Density Testing (Archimedes’ Method) |

| Sintering | Precise Temperature & Duration | Microstructure Analysis (SEM) |

| Precision Machining | CNC Accuracy & Tolerances | Dimensional Inspection (CMM) |

| Final Inspection | Overall Component Integrity | Mechanical & Thermal Testing (Tensile, TGA) |

Need a PTFE component you can trust? KINTEK specializes in manufacturing high-performance PTFE bushes, seals, liners, and custom labware for the semiconductor, medical, and industrial sectors. Our rigorous process ensures every part meets exact specifications for durability, precision, and chemical resistance. Whether you need a prototype or high-volume production, we deliver quality you can depend on. Contact our team today to discuss your project requirements!

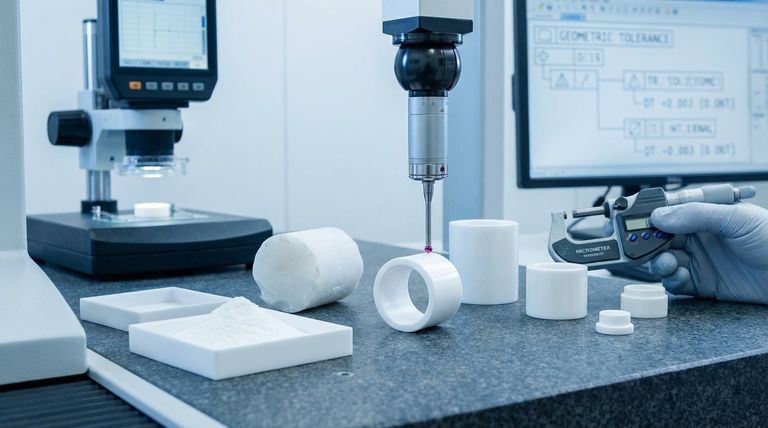

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications