At its core, Polytetrafluoroethylene (PTFE) is a high-performance synthetic fluoropolymer, a type of plastic composed entirely of carbon and fluorine. Its global recognition, often under brand names like Teflon®, comes from a unique combination of properties: it is exceptionally non-stick, has an extremely low coefficient of friction, is nearly impervious to chemical attack, and remains stable across a vast temperature range. These characteristics all stem directly from its unique and powerful molecular structure.

The uniqueness of PTFE is not a collection of separate features, but a direct result of its incredibly strong carbon-fluorine bonds. These bonds create a protective molecular "sheath" that makes the material chemically inert, exceptionally slippery, and thermally stable.

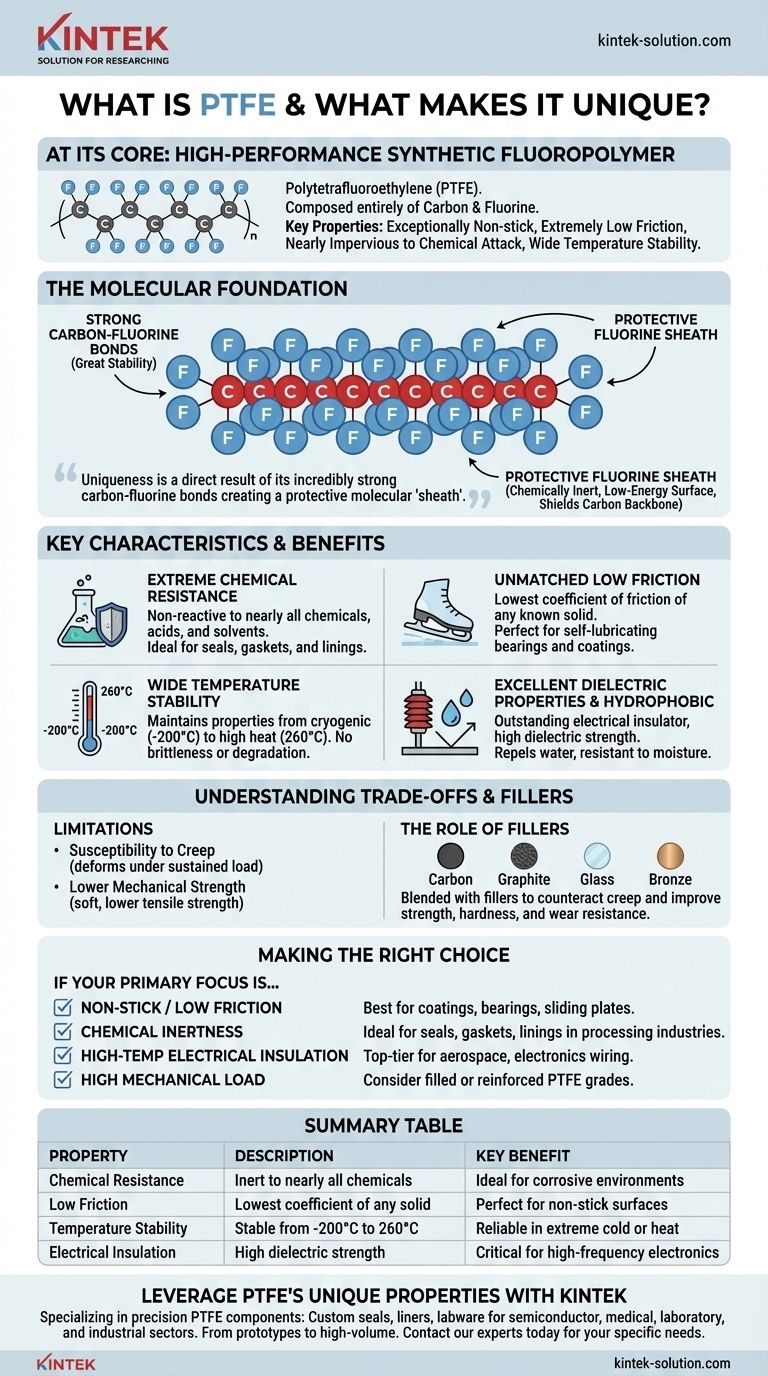

The Molecular Foundation of PTFE's Properties

To understand what makes PTFE special, we must look at its chemistry. The material's remarkable characteristics are not accidental; they are a direct consequence of its atomic makeup.

The Carbon-Fluorine Bond

PTFE consists of a long chain of carbon atoms, where each carbon is bonded to two fluorine atoms. The bond between carbon and fluorine is one of the strongest known in organic chemistry.

This exceptional bond strength gives the entire polymer molecule immense stability. It requires a great deal of energy to break these bonds, which is the foundation of PTFE’s resistance to heat and chemicals.

A Protective Sheath of Fluorine

The fluorine atoms are larger than the carbon atoms they are attached to. They effectively wrap around the carbon backbone, creating a dense, uniform, and electrically neutral sheath.

This fluorine sheath shields the vulnerable carbon chain from external chemicals, making the material almost universally inert. It also creates a very low-energy surface, which is why other substances find it so difficult to stick to PTFE.

A Deeper Look at PTFE's Key Characteristics

This unique molecular structure gives rise to a set of valuable properties that make PTFE a critical material in countless demanding applications.

Extreme Chemical Resistance

Because of its stable bonds and protective fluorine sheath, PTFE is non-reactive to nearly all chemicals, acids, and solvents. This makes it an ideal material for seals, gaskets, and linings used to handle highly corrosive substances.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any known solid, comparable to wet ice on wet ice. This means it is incredibly slippery, allowing components to slide against it with minimal energy loss, making it a premier material for self-lubricating bearings and low-friction coatings.

Wide Temperature Stability

The material maintains its properties across an exceptionally broad temperature range, from cryogenic conditions at -200°C (-328°F) up to continuous service at 260°C (500°F). It does not become brittle in extreme cold or degrade in high heat within this range.

Excellent Dielectric Properties

PTFE is an outstanding electrical insulator. It has a high dielectric strength and a low dissipation factor, meaning it can insulate against high voltages and does not lose significant energy when exposed to alternating currents, which is critical for high-frequency electronics.

Hydrophobic Nature

The material is hydrophobic, meaning it repels water and water-containing substances. This property contributes to its non-stick performance and makes it resistant to moisture absorption, ensuring its properties remain stable in humid environments.

Understanding the Trade-offs

No material is perfect, and PTFE's unique strengths come with certain mechanical limitations that are important to understand.

Susceptibility to Creep

One of the primary weaknesses of pure PTFE is its tendency to "creep" or deform over time when subjected to a sustained compressive load, especially at elevated temperatures.

The Role of Fillers

To counteract creep and improve mechanical strength, PTFE is often blended with fillers. Materials like carbon, graphite, glass, or bronze are added to create a composite material with enhanced hardness, wear resistance, and dimensional stability.

Lower Mechanical Strength

Compared to other engineering plastics, PTFE is relatively soft and has lower tensile strength and abrasion resistance. It is not typically used for applications requiring high structural rigidity without reinforcement.

Making the Right Choice for Your Goal

Selecting PTFE depends entirely on whether its unique advantages align with the primary demands of your application.

- If your primary focus is non-stick surfaces or low-friction movement: PTFE's molecular structure makes it one of the best possible choices for coatings, bearings, and sliding plates.

- If your primary focus is chemical inertness and corrosion resistance: PTFE's non-reactive nature is ideal for seals, gaskets, and vessel linings in the chemical, pharmaceutical, and food processing industries.

- If your primary focus is high-temperature electrical insulation: Its excellent dielectric properties and thermal stability make it a top-tier material for wiring and components in demanding aerospace and electronics applications.

- If your application involves high mechanical load or pressure: You should strongly consider a filled or reinforced grade of PTFE to mitigate its natural tendency to deform under stress.

Ultimately, understanding PTFE's unique molecular structure is the key to leveraging its remarkable properties for your specific engineering challenge.

Summary Table:

| Property | Description | Key Benefit |

|---|---|---|

| Chemical Resistance | Inert to nearly all chemicals, acids, and solvents. | Ideal for seals and linings in corrosive environments. |

| Low Friction | One of the lowest coefficients of friction of any solid. | Perfect for self-lubricating bearings and non-stick surfaces. |

| Temperature Stability | Stable from -200°C to 260°C (-328°F to 500°F). | Reliable performance in extreme cold or heat. |

| Electrical Insulation | High dielectric strength and low dissipation factor. | Critical for high-frequency and high-voltage electronics. |

Leverage PTFE's unique properties for your application. KINTEK specializes in manufacturing precision PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, we deliver the chemical resistance and thermal stability your project demands. Contact our experts today to discuss your specific needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- Why is PTFE compliance with USDA and FDA standards important? Ensure Safety in Food, Pharma & Medical

- How does Teflon's friction coefficient benefit mechanical applications? Reduce Wear and Energy Consumption

- What are the key characteristics of PTFE's molecular structure? Unlock the Power of the Fluorine Sheath

- How was PTFE discovered and by whom? A Serendipitous Breakthrough in Material Science

- What are the advantages of RPTFE over standard PTFE? Superior Strength and Durability for Demanding Applications

- How is PTFE utilized in the electronics and electrical industry? Essential for High-Frequency & Harsh Environments

- What are the environmental and safety considerations for Teflon and UHMW? Ensure Safe Material Selection

- What are the key differences between PTFE and RPTFE? Choose the Right Material for Your Application