For any regulated industry, PTFE's compliance with USDA and FDA standards is fundamentally a certification of safety. It verifies that the material is non-toxic and will not leach harmful substances, making it one of the few high-performance plastics approved for direct contact with food, drugs, and medical devices. This compliance is the baseline requirement that allows its other valuable properties to be utilized.

The importance of PTFE's compliance isn't just about meeting a regulatory checkbox. It's about the powerful combination of certified safety with the material's inherent physical resilience, allowing it to maintain integrity and hygiene under the extreme conditions common in food, medical, and pharmaceutical environments.

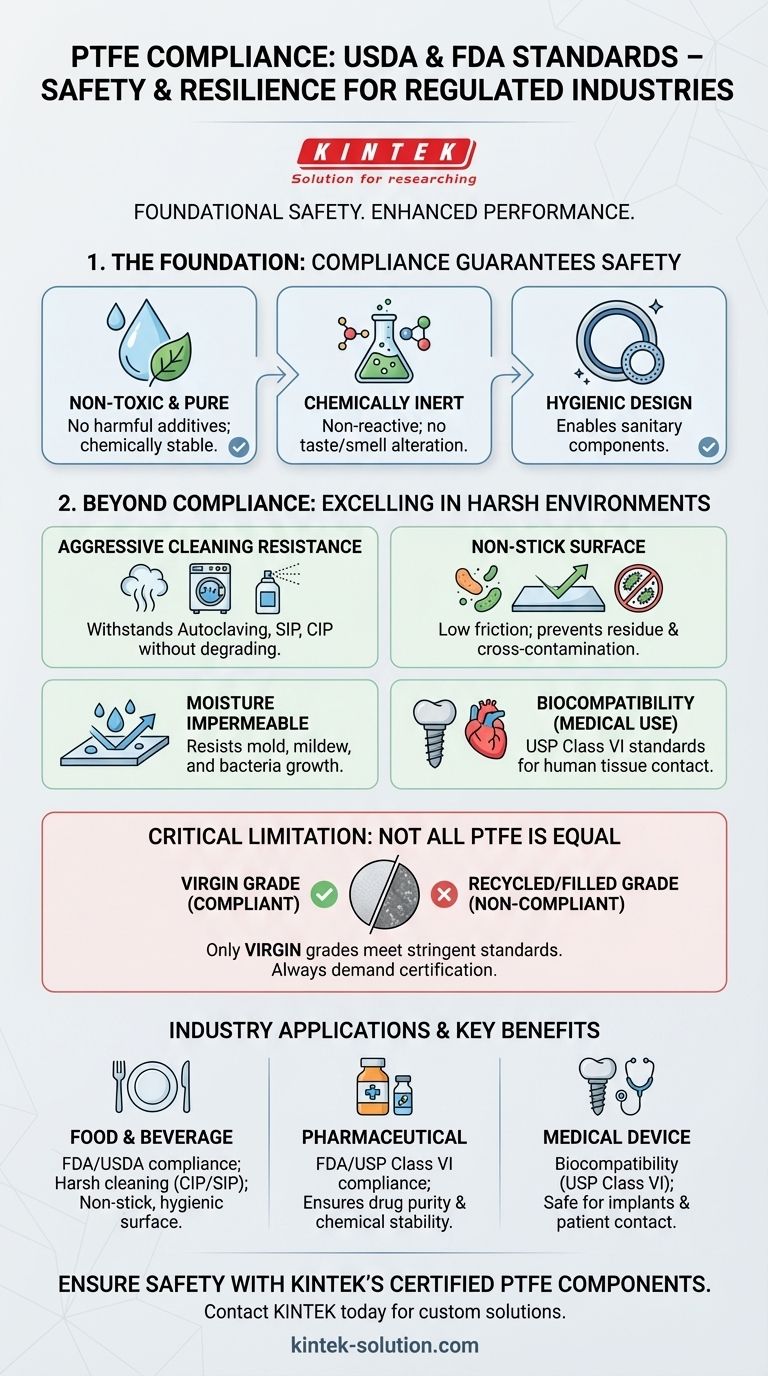

The Foundation: What FDA and USDA Compliance Guarantees

Compliance with standards set by the Food and Drug Administration (FDA) and the U.S. Department of Agriculture (USDA) is a non-negotiable requirement for materials in certain applications. This certification provides a critical assurance of safety.

Ensuring Non-Toxicity and Purity

FDA and USDA compliance guarantees that specific grades of PTFE are free from any additives or pigments that could be harmful if ingested. The regulations ensure the material is chemically stable and will not contaminate the products it touches.

Verifying Chemical Inertness

These standards confirm PTFE's non-reactive nature. It will not react with or alter the taste, smell, or composition of food products, nor will it interfere with the chemical stability of sensitive pharmaceutical compounds.

Enabling Hygienic Design

Compliance allows engineers and designers to confidently specify PTFE for components that require the highest levels of sanitation. This is crucial for parts like seals, gaskets, bellows, and liners in processing equipment.

Beyond Compliance: Why PTFE Excels in Regulated Environments

While compliance opens the door, it is PTFE's unique combination of other properties that makes it such a dominant material in these demanding sectors. These characteristics ensure it not only meets but exceeds the operational requirements for safety and performance.

Resilience to Aggressive Cleaning

Regulated industries rely on harsh cleaning and sterilization protocols. PTFE's high-temperature resistance allows it to easily withstand autoclaving, steam-in-place (SIP), and clean-in-place (CIP) processes without degrading.

A Naturally Non-Stick Surface

PTFE has an extremely low coefficient of friction. This non-stick quality prevents food, bacteria, and other residues from adhering to its surface, making equipment significantly easier to clean and mitigating the risk of cross-contamination.

Impermeable to Moisture

The material exhibits exceptionally low moisture absorption. Because it does not retain water, PTFE inherently resists the growth of mold, mildew, and bacteria, which is a critical feature for any hygienic environment.

Biocompatibility for Medical Use

For medical applications, certain grades of PTFE also meet USP Class VI standards. This is a higher level of certification that confirms the material is biocompatible and safe for contact with human tissue, making it suitable for implants and surgical devices.

Understanding the Key Limitation

While highly effective, it's crucial to recognize the primary pitfall when sourcing this material. Misunderstanding this point can lead to significant regulatory and safety failures.

Not All PTFE is Created Equal

The most critical takeaway is that only specific, virgin grades of PTFE meet these stringent standards. Industrial or recycled grades often contain fillers or impurities that render them non-compliant and unsafe for food, medical, or pharmaceutical contact. Always demand certification from your supplier.

How to Apply This to Your Project

Your specific application will determine which certification is most critical.

- If your primary focus is food and beverage processing: Prioritize FDA and USDA-compliant PTFE for its non-stick surface and ability to withstand aggressive washdown cycles.

- If your primary focus is pharmaceutical manufacturing: Select USP Class VI and FDA-compliant grades for their proven purity and non-reactivity, ensuring zero contamination of drug products.

- If your primary focus is medical device design: Require PTFE that meets both FDA regulations and biocompatibility standards like USP Class VI to guarantee patient safety.

Ultimately, choosing a compliant grade of PTFE is a foundational decision that ensures product safety, operational reliability, and regulatory peace of mind.

Summary Table:

| Industry | Key PTFE Compliance & Benefits |

|---|---|

| Food & Beverage | FDA/USDA compliance; withstands harsh cleaning (CIP/SIP); non-stick, hygienic surface. |

| Pharmaceutical | FDA/USP Class VI compliance; ensures drug purity and chemical stability. |

| Medical Device | Biocompatibility (USP Class VI); safe for implants and patient contact. |

Ensure your product's safety and compliance with certified PTFE components from KINTEK.

For industries where material purity is non-negotiable—such as semiconductor, medical, laboratory, and specialized industrial applications—using the correct, certified PTFE is critical. KINTEK manufactures high-purity PTFE components (seals, liners, labware, and more) that meet stringent FDA, USDA, and USP Class VI standards. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your components are safe, reliable, and fully compliant.

Contact KINTEK today to discuss your project requirements and receive a quote for compliant PTFE solutions tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications