The defining benefit of Teflon's friction coefficient is its exceptionally low value—among the lowest of any solid material. This property allows mechanical components to slide against each other with minimal resistance, which directly translates to a significant reduction in wear, a decrease in energy consumption, and a much longer operational lifespan for the parts.

The core value of Teflon in mechanical design is not simply that it's "slippery," but that its low friction creates a self-lubricating system. This eliminates the need for external oils and greases, leading to cleaner, more efficient, and lower-maintenance machinery.

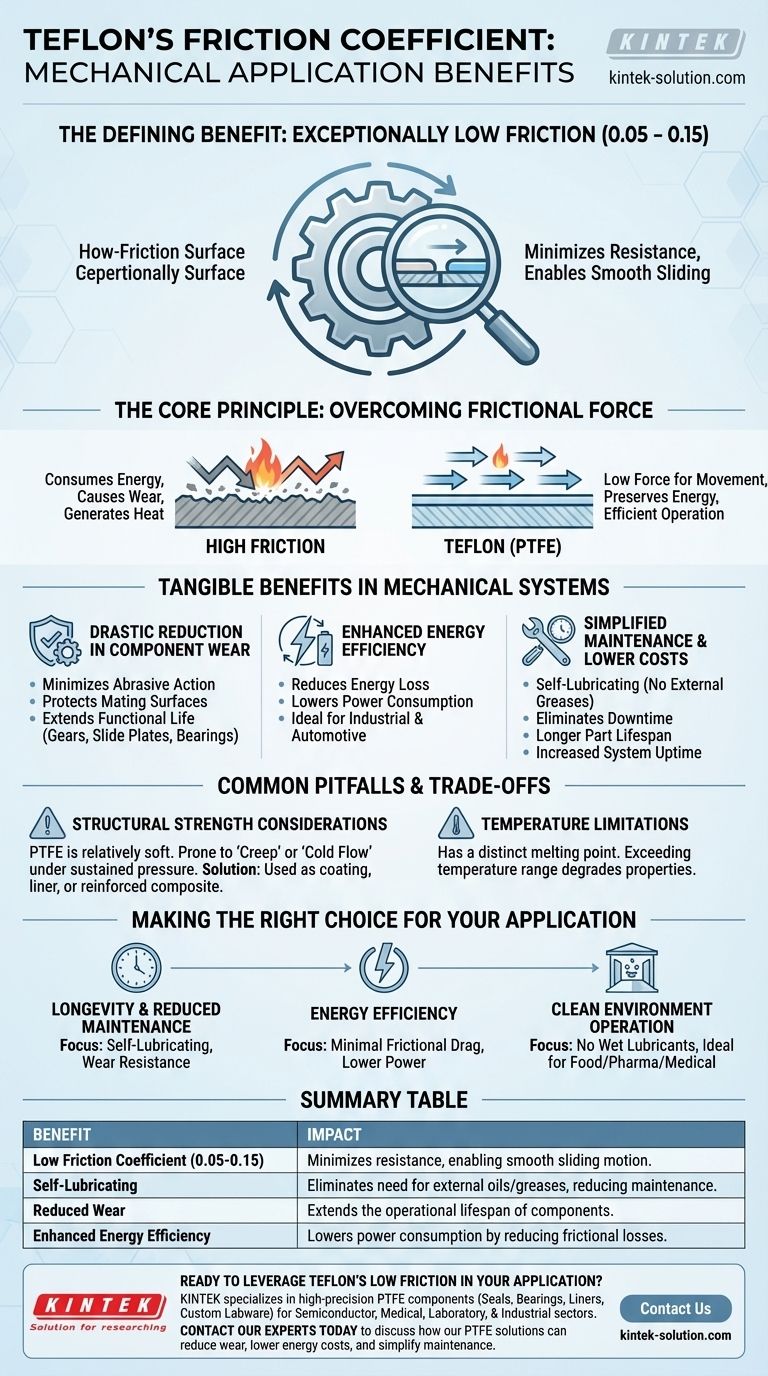

The Core Principle: Overcoming Frictional Force

Friction is a fundamental force in any mechanical system with moving parts. It generates heat, consumes energy, and causes material to wear away over time. Materials with a high coefficient of friction resist motion, while those with a low coefficient allow for smooth, easy sliding.

What a Low Friction Coefficient Means

Teflon, or Polytetrafluoroethylene (PTFE), has a static and dynamic coefficient of friction between 0.05 and 0.15. This figure is exceptionally low.

This means that very little force is required to initiate or maintain movement between a Teflon surface and another component. The energy that would otherwise be lost to frictional heat is instead preserved, allowing the system to operate more efficiently.

The Self-Lubricating Effect

Perhaps the most significant consequence of this low friction is Teflon's self-lubricating nature.

Many mechanical systems rely on external lubricants like oil or grease to reduce friction between parts. Teflon components, such as bearings and bushings, often eliminate this need entirely, as the material itself provides the necessary low-friction surface.

Tangible Benefits in Mechanical Systems

The theoretical advantage of low friction translates into several practical, high-impact benefits for engineers and operators.

Drastic Reduction in Component Wear

When parts slide smoothly, the abrasive action that degrades surfaces is minimized.

Using Teflon for gears, slide plates, and bearings protects mating surfaces from premature wear. This directly extends the functional life of both the Teflon part and the component it touches.

Enhanced Energy Efficiency

Friction is a direct source of energy loss in machinery.

By minimizing this resistance, Teflon-coated or solid Teflon parts allow systems to run with less power. This reduction in energy consumption is a critical advantage in everything from industrial machinery to automotive applications.

Simplified Maintenance and Lower Costs

The combination of extreme durability and self-lubrication significantly reduces maintenance requirements.

There is no need to schedule downtime for lubrication, and parts simply last longer between replacements. This results in lower lifetime operational costs and increased system uptime.

Common Pitfalls and Trade-offs

While its frictional properties are outstanding, Teflon is not a universal solution. An objective analysis requires understanding its limitations.

Structural Strength Considerations

PTFE is a relatively soft material and is not suitable for high-load structural applications on its own. It has a tendency to deform under sustained pressure, a phenomenon known as "creep" or "cold flow."

For this reason, it is often used as a coating, a liner for a stronger metal bearing, or as a composite material reinforced with other fillers to improve its mechanical strength.

Temperature Limitations

While Teflon performs well in high-temperature environments, such as in bellow mechanical seals, it has a distinct melting point. Exceeding its operational temperature range will cause it to degrade, compromising its structural and frictional properties.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary engineering goal.

- If your primary focus is longevity and reduced maintenance: Teflon's self-lubricating nature and resistance to wear are its most compelling features, directly reducing downtime and replacement costs.

- If your primary focus is energy efficiency: Its minimal frictional drag is a key advantage, translating directly to lower power consumption in any system with sliding parts.

- If your primary focus is operation in a clean environment: The elimination of wet lubricants makes it an ideal choice for food processing, pharmaceutical, or medical applications where contamination is a critical concern.

Ultimately, leveraging Teflon's uniquely low friction is about designing more efficient, reliable, and cost-effective mechanical systems.

Summary Table:

| Benefit | Impact on Mechanical Systems |

|---|---|

| Low Friction Coefficient (0.05-0.15) | Minimizes resistance, enabling smooth sliding motion. |

| Self-Lubricating | Eliminates need for external oils/greases, reducing maintenance. |

| Reduced Wear | Extends the operational lifespan of components. |

| Enhanced Energy Efficiency | Lowers power consumption by reducing frictional losses. |

Ready to leverage Teflon's low friction in your application?

KINTEK specializes in manufacturing high-precision PTFE components—including seals, bearings, liners, and custom labware—that harness these exact benefits for demanding industries. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom fabrication services from prototype to high-volume production ensure you get a component optimized for longevity, efficiency, and clean operation.

Contact our experts today to discuss how our PTFE solutions can reduce wear, lower energy costs, and simplify maintenance for your machinery.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech