From a safety perspective, the primary consideration for Teflon (PTFE) is its potential to release toxic fumes when heated above 300°C (572°F). In contrast, UHMW (Ultra-High Molecular Weight Polyethylene) is generally considered non-toxic and odorless, with its main limitation being physical instability at high temperatures rather than chemical off-gassing.

The core difference is the nature of the risk: Teflon's risk is a chemical hazard tied directly to high temperatures, while UHMW's risk is a physical or mechanical failure if used outside its stable temperature range.

Teflon (PTFE): A Closer Look at the Risks

Teflon is renowned for its chemical inertness, but this stability has a critical temperature threshold that dictates its safe use.

The Overheating Hazard

The most significant safety concern with Teflon is thermal decomposition. When heated above 300°C, it can release harmful particulate fumes.

Inhaling these fumes can lead to a temporary flu-like condition, highlighting the importance of temperature control in applications involving Teflon.

Historical Manufacturing Concerns

Historically, the manufacturing of Teflon involved a processing aid called PFOA (perfluorooctanoic acid), which raised environmental and health concerns.

It is crucial to note that reputable manufacturers have since phased out the use of PFOA in their processes, mitigating this specific risk in modern materials.

General Environmental Profile

Under normal operating temperatures, Teflon is extremely stable and non-reactive. This inertness means it doesn't readily break down or leach chemicals into the environment.

However, its primary safety profile is defined by the strict avoidance of overheating.

UHMW: Understanding Its Safety Profile

UHMW is known for its biocompatibility and is widely used in applications where safety and non-toxicity are paramount.

A Fundamentally Non-Toxic Material

UHMW is inherently non-toxic and odorless. Its chemical stability makes it a safe choice for applications involving direct contact, including medical implants and food processing equipment.

Unlike Teflon, it does not pose a risk of releasing hazardous fumes when heated.

The Limit of Thermal Instability

The main limitation of UHMW is its thermal instability, but this is a performance issue, not a toxicity one.

The material can expand, warp, or lose its structural integrity at elevated temperatures, making it unsuitable for high-precision or high-heat applications. This failure is mechanical, not chemical.

Understanding the Trade-offs

Choosing between these materials requires a clear understanding of the application's operating environment, particularly its temperature range.

Scenario 1: High-Temperature Environment

Teflon is superior in high-heat applications, but only up to its specified limit. Exceeding this limit introduces a significant chemical hazard.

UHMW is not a viable option for high-temperature environments due to its poor dimensional stability.

Scenario 2: Human or Food Contact

Both materials can be used safely, but their risk profiles differ. UHMW is widely trusted in medical and food-grade applications due to its non-toxic nature.

Teflon is also used, but with the strict condition that temperature controls are in place to prevent any possibility of overheating and fume release.

Making the Right Choice for Your Application

Your final decision must be based on the specific operational demands and potential failure modes of your project.

- If your primary focus is high-temperature performance (below 300°C): Teflon is the appropriate choice, provided you can guarantee temperature stability.

- If your primary focus is biocompatibility and safety at low temperatures: UHMW is the safer, more reliable option with no risk of toxic off-gassing.

- If your primary focus is high-precision mechanical parts: Neither may be ideal if significant temperature fluctuations are expected, but UHMW's thermal expansion is a more immediate design constraint.

Ultimately, aligning the material's specific safety profile with your application's environment is the key to a safe and effective design.

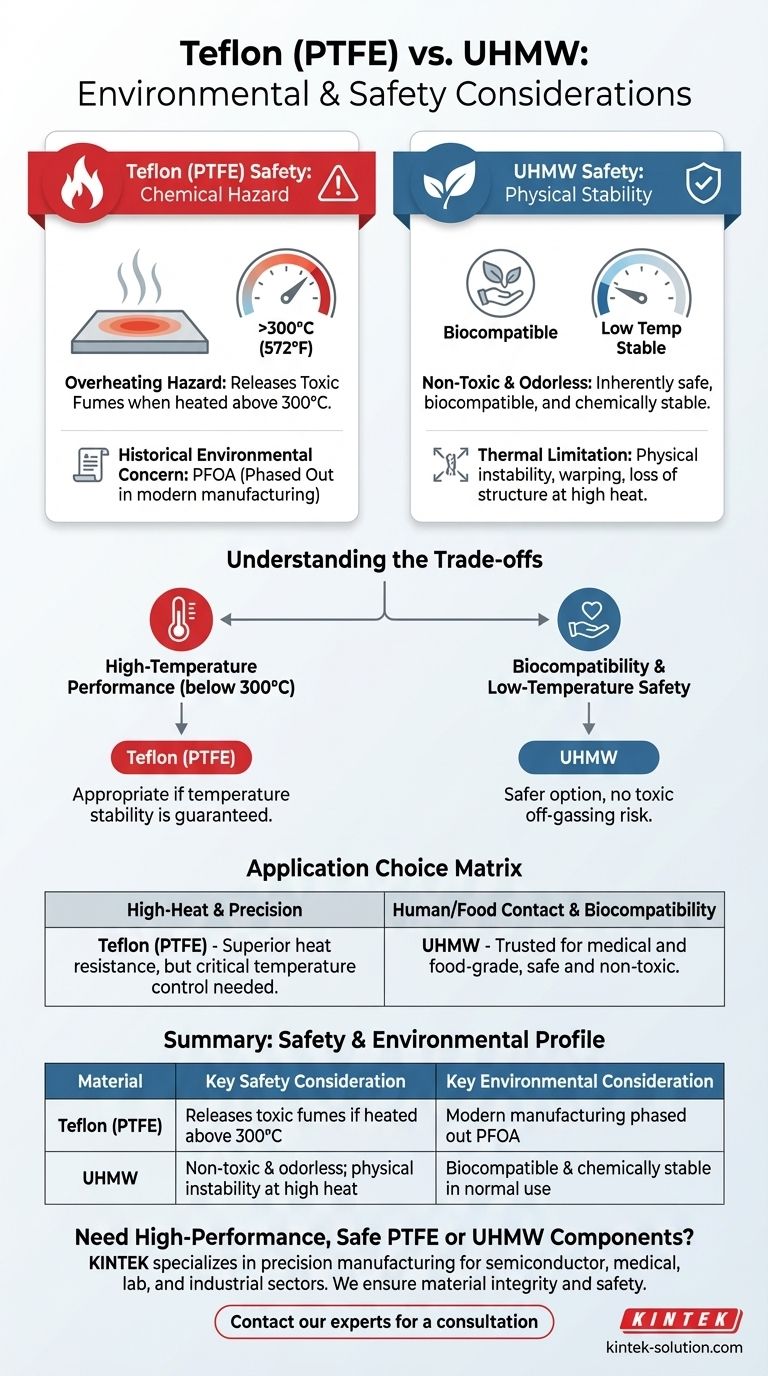

Summary Table:

| Material | Key Safety Consideration | Key Environmental Consideration |

|---|---|---|

| Teflon (PTFE) | Releases toxic fumes if heated above 300°C (572°F) | Modern manufacturing has phased out the use of PFOA |

| UHMW | Non-toxic and odorless; risk is mechanical failure at high heat | Biocompatible and chemically stable under normal use |

Need High-Performance, Safe PTFE or UHMW Components?

Choosing the right material is critical for the safety and success of your project. KINTEK specializes in the precision manufacturing of PTFE components (like seals, liners, and labware) and UHMW parts for the semiconductor, medical, laboratory, and industrial sectors.

We ensure material integrity and safety from prototype to high-volume production. Let's discuss your application's requirements and build a safer, more reliable solution together.

Contact our experts today for a consultation

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability