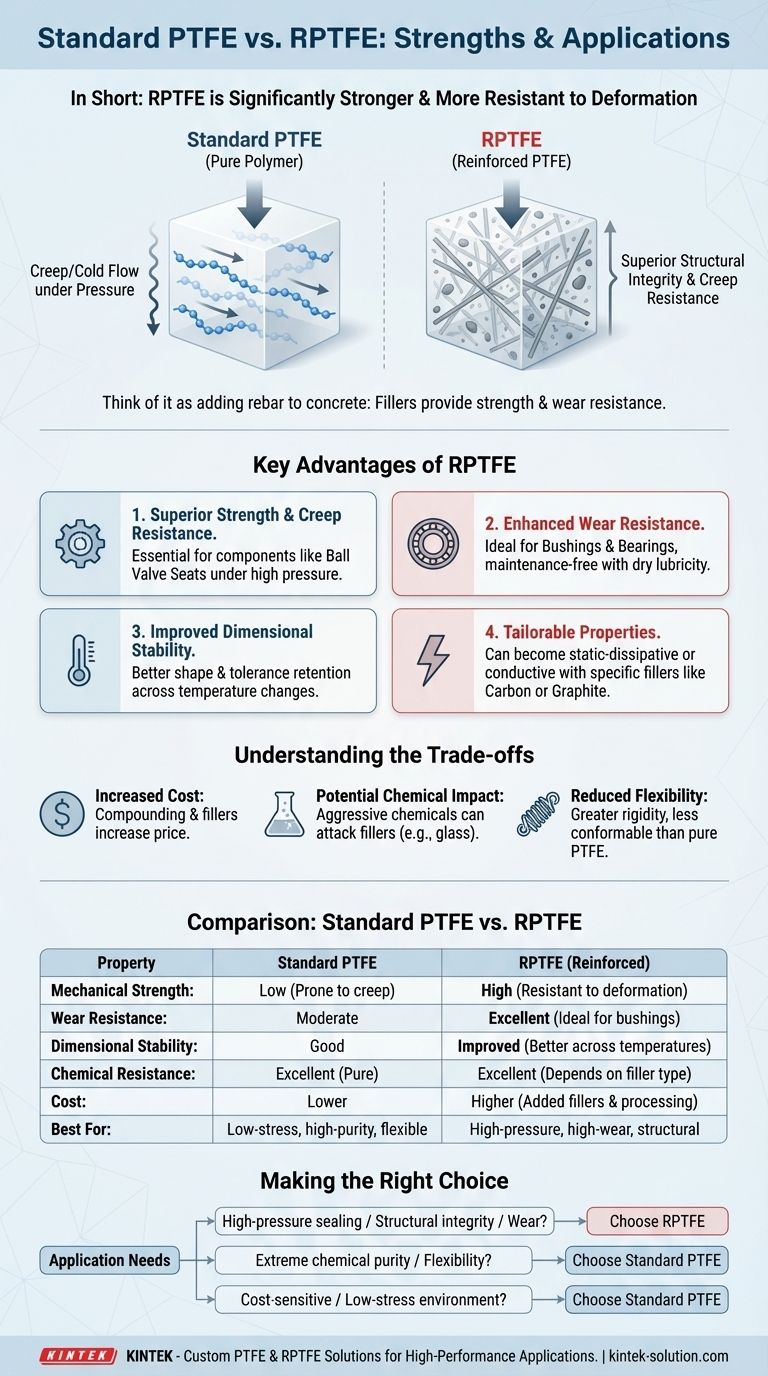

In short, RPTFE is significantly stronger and more resistant to deformation under pressure than standard PTFE. This is achieved by adding reinforcing fillers, such as glass fiber or carbon, to the pure PTFE base. While standard PTFE is known for its low friction and chemical inertness, it is mechanically weak and can "creep" or deform under load; RPTFE is specifically engineered to solve this problem for more demanding applications.

The core difference is simple: standard PTFE is a pure polymer, while RPTFE (Reinforced Polytetrafluoroethylene) is a composite material. Think of it as adding rebar to concrete—the fillers in RPTFE provide the structural strength and wear resistance that pure PTFE lacks.

The Fundamental Difference: Pure vs. Reinforced

To understand the advantages, you must first understand the core distinction in their composition. The performance of each material stems directly from this difference.

Standard PTFE (Polytetrafluoroethylene)

Standard PTFE is a pure polymer consisting only of carbon and fluorine bonds. This simple, stable structure gives it its famous properties: an extremely low coefficient of friction (it's very slippery), excellent chemical resistance, and high-purity for sensitive applications.

However, this purity is also its primary weakness. Under mechanical load or pressure, the polymer chains can easily slide past one another, causing the material to deform permanently. This is often called creep or cold flow.

RPTFE (Reinforced PTFE)

RPTFE begins with the same PTFE base but enhances it by blending in filler materials. The "R" literally stands for "Reinforced."

Common fillers include glass fibers, carbon, or graphite. These fillers are dispersed within the PTFE matrix, creating a composite material with fundamentally different mechanical properties.

Key Advantages of Reinforcing PTFE

Adding fillers directly addresses the inherent weaknesses of the pure polymer, making RPTFE the superior choice for applications involving mechanical stress.

Superior Strength and Creep Resistance

This is the most critical advantage. The embedded fillers provide a rigid internal structure that prevents the PTFE from deforming under pressure.

This makes RPTFE essential for components like ball valve seats, which must maintain a tight seal under constant high pressure without extruding or failing over time.

Enhanced Wear Resistance

The reinforcing fillers make the material harder and more durable. This dramatically improves its resistance to abrasive wear and extends the service life of components.

This is why RPTFE is often used for bushings and bearings, where it can operate maintenance-free with dry lubricity and minimal wear.

Improved Dimensional Stability

Fillers can reduce the material's tendency to expand or contract with temperature changes. RPTFE maintains its shape and tolerances better than pure PTFE across a wider operational temperature range.

Tailorable Properties

The type and percentage of filler can be adjusted to achieve specific outcomes. While pure PTFE is an excellent electrical insulator, adding carbon or graphite can make RPTFE static-dissipative or even electrically conductive for specialized needs.

Understanding the Trade-offs

Choosing RPTFE is not without its considerations. Its advantages in strength come with specific trade-offs that are important to recognize.

Increased Cost

The process of compounding PTFE with fillers and the cost of the fillers themselves make RPTFE more expensive than standard, unfilled PTFE.

Potential Impact on Chemical Resistance

While the PTFE base remains highly inert, certain aggressive chemicals can attack the filler material. For example, glass fillers may not be suitable for strong alkalis or hydrofluoric acid. In such cases, pure PTFE might be the safer choice.

Reduced Flexibility

The added reinforcement that provides strength also makes RPTFE more rigid and less flexible than pure PTFE. For applications requiring a seal to conform to a highly irregular surface, the softness of standard PTFE might be an advantage.

Making the Right Choice for Your Application

Your final decision must be based on the specific demands of the operating environment.

- If your primary focus is high-pressure sealing or structural integrity: Choose RPTFE for its superior strength and resistance to deformation, especially in components like valve seats, high-load bearings, or piston rings.

- If your primary focus is extreme chemical purity or flexibility: Choose standard PTFE, particularly in food-grade, medical applications, or for low-pressure gaskets that need to conform to imperfect flanges.

- If your primary focus is cost-sensitivity in a low-stress environment: Standard PTFE is the more economical choice for applications like simple linings, lab equipment, or gaskets where mechanical load is not a concern.

By understanding that RPTFE is engineered specifically to overcome the mechanical limitations of PTFE, you can confidently select the material built to withstand your application's unique pressures.

Summary Table:

| Property | Standard PTFE | RPTFE (Reinforced) |

|---|---|---|

| Mechanical Strength | Low (prone to creep/cold flow) | High (resistant to deformation) |

| Wear Resistance | Moderate | Excellent (ideal for bearings, bushings) |

| Dimensional Stability | Good | Improved (better across temperature ranges) |

| Chemical Resistance | Excellent (pure polymer) | Excellent, but can depend on filler type |

| Cost | Lower | Higher (due to added fillers and processing) |

| Best For | Low-stress, high-purity, flexible applications | High-pressure, high-wear, structural applications |

Need a custom PTFE or RPTFE component that can withstand high pressure and wear?

At KINTEK, we specialize in manufacturing high-performance PTFE and RPTFE components—including seals, liners, labware, and custom parts—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, ensure you get the exact material solution for your demanding application.

Contact our experts today to discuss your project requirements and discover how our materials expertise can enhance your product's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability