At a fundamental level, the key difference is reinforcement. RPTFE (Reinforced Polytetrafluoroethylene) is standard PTFE that has been blended with filler materials like glass fiber, carbon, or bronze. This reinforcement is specifically designed to overcome PTFE’s primary weakness: its tendency to deform under pressure. While pure PTFE is chemically inert and flexible, RPTFE offers significantly greater strength, wear resistance, and dimensional stability.

The choice between PTFE and RPTFE is a classic engineering trade-off. PTFE provides ultimate chemical purity and cost-effectiveness, while RPTFE sacrifices these for vastly improved mechanical performance and stability under physical load.

From Pure Polymer to Reinforced Composite

To understand the differences, it's best to view RPTFE not as a separate material, but as an evolution of PTFE designed for more demanding physical environments.

The Foundation: Pure PTFE

Polytetrafluoroethylene (PTFE) is a fluorocarbon polymer known for its remarkable properties, often recognized by the brand name Teflon.

Its structure of only carbon and fluorine bonds gives it extreme chemical resistance and a very low coefficient of friction. However, this same simple structure makes it mechanically soft and highly susceptible to "creep" or cold flow—a slow, continuous deformation when subjected to pressure.

The Enhancement: What "Reinforced" Means

RPTFE is a composite material. During its manufacturing, specific filler materials are mixed into the PTFE matrix.

These fillers are not just a simple additive; they become an integral part of the material's structure, fundamentally changing its physical behavior.

The Impact of the Fillers

The reinforcing fillers act much like rebar in concrete. They provide a rigid internal scaffold that prevents the soft PTFE polymer from deforming under load.

This addition dramatically improves the material's strength and wear properties, making it suitable for applications where pure PTFE would quickly fail.

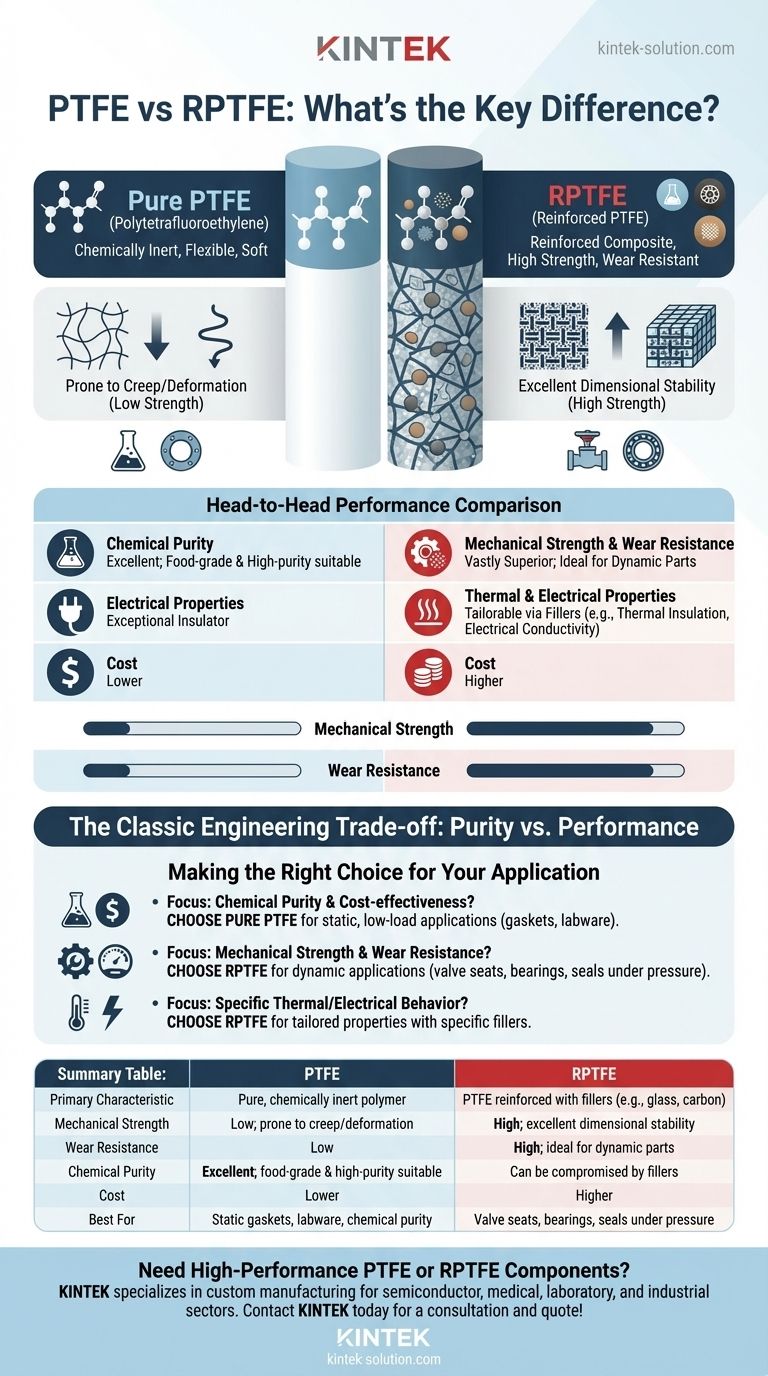

A Head-to-Head Performance Comparison

The inclusion of fillers creates clear performance distinctions between the two materials.

Mechanical Strength and Wear Resistance

This is the primary reason RPTFE exists. It is vastly superior to pure PTFE in strength, rigidity, and resistance to abrasion and wear.

Applications involving pressure, friction, or moving parts—like valve seats or bearings—almost always require the mechanical integrity of RPTFE.

Chemical Inertness and Purity

Pure PTFE is the clear winner here. It is one of the most chemically inert substances known and is suitable for food-grade and high-purity applications.

The fillers in RPTFE can compromise this purity. They may react with certain aggressive chemicals and are generally not considered food-safe.

Thermal and Electrical Properties

Pure PTFE is an exceptional electrical insulator. The properties of RPTFE, however, can be tailored by the choice of filler.

Adding glass fiber can enhance thermal insulation, while fillers like carbon or graphite can increase electrical conductivity, which is useful for dissipating static electricity.

Understanding the Trade-offs and Limitations

Choosing RPTFE introduces new considerations that are not present with pure PTFE.

Cost vs. Performance

RPTFE is more expensive than PTFE due to the additional materials and more complex manufacturing process.

This higher cost is only justified when the application's mechanical demands exceed the capabilities of pure PTFE.

Purity and Application Constraints

The potential reactivity of the fillers is a critical limitation. You must ensure that the specific grade of RPTFE and its reinforcing agent are compatible with the chemical environment of your application.

Manufacturing and Production

RPTFE is often less suitable for mass production than pure PTFE. Its properties also mean it cannot be cemented and must rely on conventional welding or mechanical fastening techniques.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your primary operational goal.

- If your primary focus is chemical purity and cost-effectiveness: Choose pure PTFE, especially for static, low-load applications like gaskets in non-abrasive environments or laboratory equipment.

- If your primary focus is mechanical strength and wear resistance: Choose RPTFE for any dynamic application like valve seats, bearings, or seals operating under pressure where dimensional stability is critical.

- If your primary focus is managing specific thermal or electrical behavior: RPTFE offers the flexibility to add fillers that can increase thermal insulation or, conversely, improve electrical conductivity to meet precise requirements.

Ultimately, understanding that RPTFE is a tool for solving PTFE's inherent mechanical weaknesses empowers you to select the precise material for your engineering challenge.

Summary Table:

| Property | PTFE | RPTFE |

|---|---|---|

| Primary Characteristic | Pure, chemically inert polymer | PTFE reinforced with fillers (e.g., glass, carbon) |

| Mechanical Strength | Low; prone to creep/deformation | High; excellent dimensional stability |

| Wear Resistance | Low | High; ideal for dynamic parts |

| Chemical Purity | Excellent; food-grade & high-purity suitable | Can be compromised by fillers |

| Cost | Lower | Higher |

| Best For | Static gaskets, labware, chemical purity | Valve seats, bearings, seals under pressure |

Need High-Performance PTFE or RPTFE Components?

Selecting the right material is critical for the performance and longevity of your components. KINTEK specializes in the precision manufacturing of custom PTFE and RPTFE parts—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We help you navigate the trade-offs to ensure optimal material selection, offering custom fabrication from prototypes to high-volume orders. Let our expertise in fluoropolymers solve your most demanding engineering challenges.

Contact KINTEK today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the temperature range and mechanical properties of PTFE? The Ultimate Guide to Performance

- What are the key characteristics of PTFE (Teflon)? Unlock Superior Chemical & Thermal Performance

- What is PTFE commonly known as and when was it developed? The 'Plastics King' for Extreme Performance

- What environmental resistances does PTFE offer? Unmatched Durability for Harsh Conditions

- What role does PTFE play in automotive manufacturing? Enhancing Vehicle Durability and Efficiency

- What factors should be considered when choosing PTFE for a specific application? A Guide to Virgin vs. Filled Grades

- Why has PTFE fascinated scientists and science students? Unlocking the Secrets of a Wonder Material

- What are the physical properties of Teflon? Unlocking PTFE's Non-Stick, Heat-Resistant Power