Yes, a PTFE bottle is exceptionally well-suited for ultra-pure applications. Its molecular structure makes it one of the most chemically inert and non-reactive polymers available, ensuring that the container does not leach contaminants or interact with the high-purity substances stored within it.

The core reason PTFE is trusted in sensitive environments is its extreme chemical inertness. This property prevents the container itself from becoming a source of contamination, thereby preserving the absolute integrity of ultra-pure liquids, solvents, and samples.

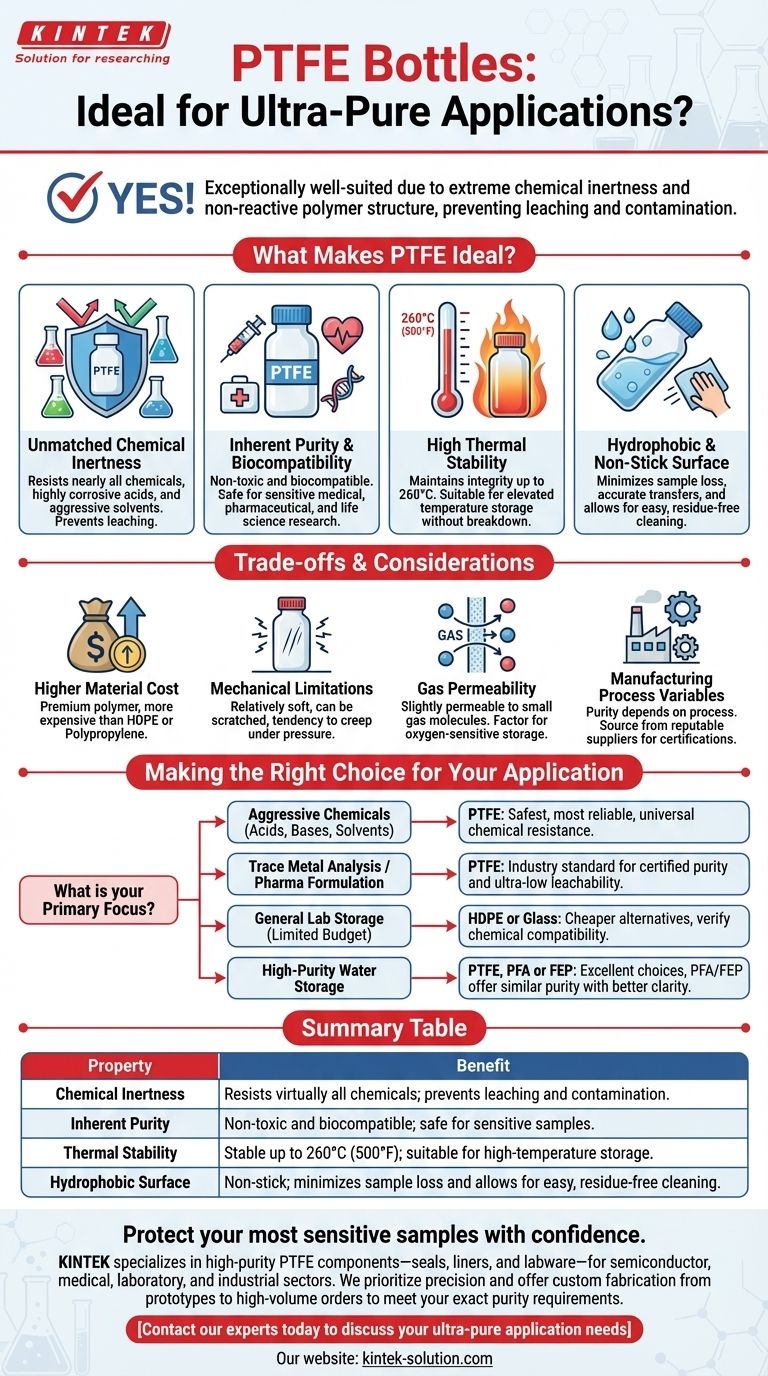

What Makes PTFE Ideal for High-Purity Containment?

The suitability of PTFE (Polytetrafluoroethylene) is not based on a single feature, but on a combination of powerful material properties. Understanding these is key to trusting it with your most sensitive work.

Unmatched Chemical Inertness

PTFE is renowned for its resistance to nearly all chemicals, including highly corrosive acids and aggressive solvents. This means the bottle will not degrade, dissolve, or react with its contents.

This lack of reactivity is what prevents leaching, where ions or molecules from the container material migrate into the sample. For ultra-pure applications, this is the most critical factor.

Inherent Purity and Biocompatibility

The material itself is inherently pure and non-toxic. PTFE is widely used in demanding medical applications, including catheters, syringes, and bio-containment vessels, because it does not cause adverse reactions with biological tissues.

This biocompatibility is a strong indicator of its purity and makes it a safe choice for pharmaceutical research and other life science applications where even trace toxicity is unacceptable.

High Thermal Stability

PTFE maintains its integrity and properties over a very wide temperature range, remaining stable up to 260°C (500°F).

This allows it to be used for storing substances at elevated temperatures without risk of material breakdown, which could otherwise release impurities.

Hydrophobic and Non-Stick Surface

The famous non-stick surface of PTFE provides two benefits for high-purity work. First, it minimizes the amount of sample that adheres to the container walls, ensuring accurate transfers.

Second, it makes the bottles easier to clean thoroughly without requiring harsh cleaning agents that could leave behind their own residue.

Understanding the Trade-offs and Considerations

While PTFE is an outstanding material, no choice is without its context. A complete technical assessment requires acknowledging its limitations.

Higher Material Cost

PTFE is a premium performance polymer, and its cost reflects that. It is significantly more expensive than common laboratory plastics like HDPE (high-density polyethylene) or polypropylene. Its use is typically reserved for applications where its unique properties are essential.

Mechanical Limitations

PTFE is a relatively soft material. It can be scratched, and it is not as rigid or durable against physical impact as other plastics. It also has a tendency to "creep," or slowly deform, under sustained pressure.

Gas Permeability

While PTFE creates an excellent barrier against liquids, it is slightly permeable to certain small gas molecules. For applications involving long-term storage of materials that are highly sensitive to oxygen or other atmospheric gases, this may be a factor to evaluate.

Manufacturing Process Variables

For the most demanding applications, such as in the semiconductor industry, the purity of the final bottle depends not just on the raw PTFE resin but also on the manufacturing process. Always source from reputable suppliers who can provide certifications regarding cleanliness and trace metal content.

Making the Right Choice for Your Application

Use your primary goal to determine if PTFE is the correct choice or if another material is more appropriate.

- If your primary focus is storing aggressive acids, bases, or organic solvents: PTFE is the safest and most reliable choice due to its near-universal chemical resistance.

- If your primary focus is trace metal analysis or pharmaceutical formulation: PTFE's certified purity and extremely low leachability make it the industry standard for preventing sample contamination.

- If your primary focus is general lab storage on a limited budget: Consider less expensive alternatives like HDPE or glass, but always verify their chemical compatibility with your specific substance first.

- If your primary focus is storing high-purity water: While PTFE is excellent, high-quality PFA (Perfluoroalkoxy) or FEP (Fluorinated Ethylene Propylene) bottles are also common and offer similar purity with better clarity.

By understanding its distinct properties and practical trade-offs, you can confidently specify PTFE for applications where purity is paramount.

Summary Table:

| Property | Benefit for Ultra-Pure Applications |

|---|---|

| Chemical Inertness | Resists virtually all chemicals; prevents leaching and contamination. |

| Inherent Purity | Non-toxic and biocompatible; safe for sensitive samples. |

| Thermal Stability | Stable up to 260°C (500°F); suitable for high-temperature storage. |

| Hydrophobic Surface | Non-stick; minimizes sample loss and allows for easy, residue-free cleaning. |

Protect your most sensitive samples with confidence. KINTEK specializes in manufacturing high-purity PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision and offer custom fabrication from prototypes to high-volume orders to meet your exact purity requirements. Contact our experts today to discuss your ultra-pure application needs.

Visual Guide

Related Products

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What is the recommended storage method for PTFE stopcock plugs when not in use? Prevent Seizing and Leaks

- What are the key advantages of using PTFE chromatography vials? Ensure Sample Integrity and Accurate Results

- Why is PTFE considered an essential material for laboratory applications? Unmatched Chemical Inertness & Thermal Stability

- Which sensitive techniques are compatible with PTFE lined vials? Ensure Accurate Trace-Level Analysis

- Why is the shelf life of PTFE/silicone septa a concern? Prevent Analytical Errors with Reliable Seals

- What are the key properties of PTFE that make it suitable for chromatography septums? Ensure Sample Integrity and Reliable Results

- What issue arises from the gas permeability of PTFE/silicone septa? Protect Your Sample Integrity

- What types of PTFE liners are available for bottle caps? Choose Between Solid PTFE or Composite Liners