The shelf life of PTFE/silicone septa is a critical concern because these components degrade over time, losing the physical properties required to maintain a perfect seal. This degradation directly threatens the integrity of your analysis by allowing sample evaporation or contamination, which can invalidate results and waste valuable resources.

An aging septum is not merely a worn-out component; it is a significant source of analytical error. Understanding its limited lifespan is fundamental to ensuring the accuracy and reliability of your experimental data.

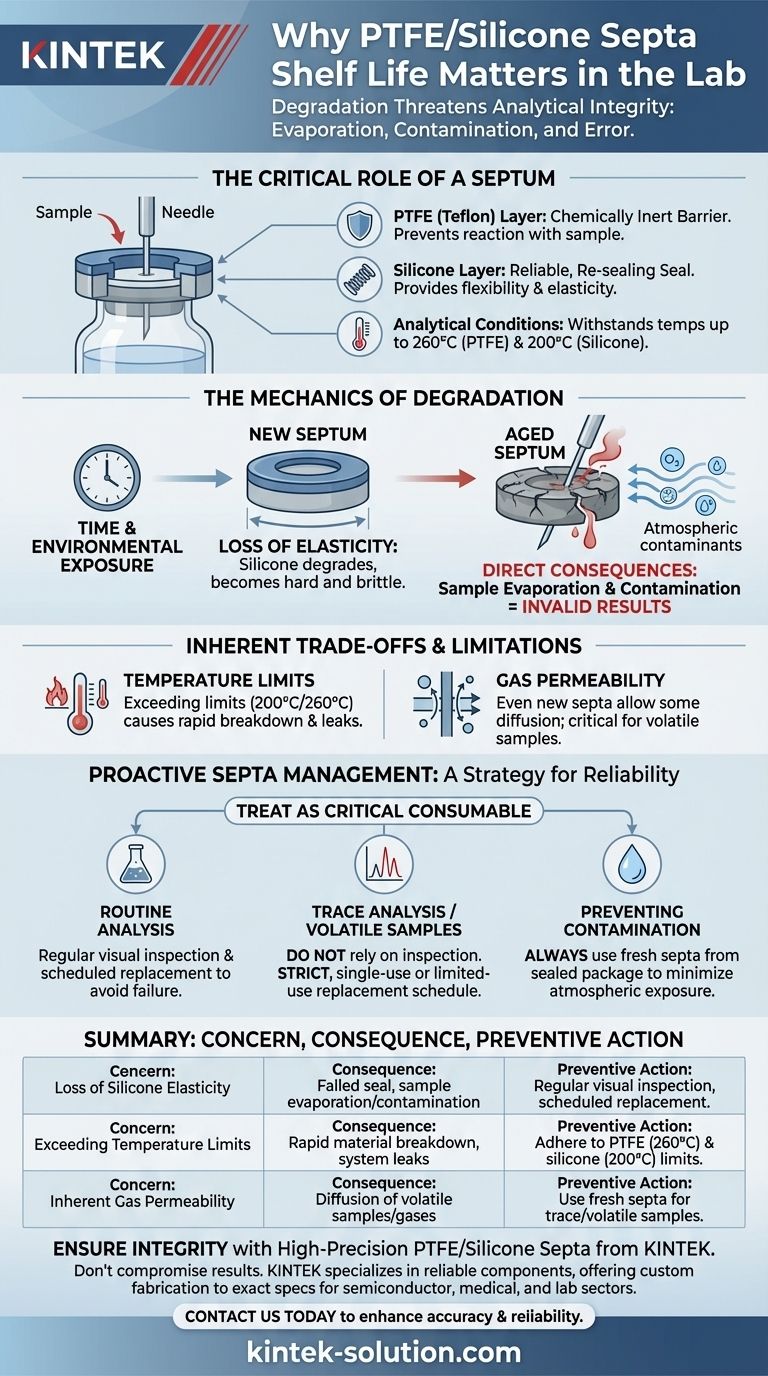

The Role of a Septum in Analytical Integrity

A PTFE/silicone septum is engineered to perform several critical functions simultaneously. It is the gatekeeper that protects the sample from the outside world while allowing controlled access for injection.

Providing a Chemically Inert Barrier

The PTFE (Teflon) layer is the first point of contact for the sample. Its primary advantage is its excellent chemical inertness, which prevents it from reacting with or adsorbing sample components, thus preserving analytical integrity.

Ensuring a Reliable Seal

The silicone layer provides the flexibility and elasticity necessary for a reliable, leak-proof seal. After being punctured by a needle, a high-quality silicone septum re-seals itself, preventing sample loss and contamination from the surrounding atmosphere.

Withstanding Analytical Conditions

These septa are designed to tolerate a range of temperatures, making them suitable for many analytical techniques. The PTFE layer can typically withstand up to 260°C, while the silicone is generally stable up to 200°C.

Why Shelf Life Matters: The Mechanics of Degradation

The effectiveness of a septum is temporary. Over time, environmental exposure and material aging compromise its ability to function as designed, even if it has never been used.

The Loss of Elasticity

The primary failure mode is the degradation of the silicone. It gradually loses its elasticity, becoming harder and more brittle. This process robs the septum of its ability to create a tight seal against the vial or inlet.

Compromised Sealing Properties

A hardened, inelastic septum cannot properly re-seal after being punctured. This creates a pathway for analytes to escape or for air to enter, fundamentally compromising the sample environment.

The Direct Consequences of a Failed Seal

A failed seal leads directly to critical analytical errors. The most common issues are sample evaporation, which concentrates non-volatile components, and contamination from atmospheric gases like oxygen and moisture, which can degrade sensitive samples.

Understanding the Inherent Trade-offs

While highly effective, PTFE/silicone septa are not a perfect solution for every scenario. Recognizing their limitations is key to using them correctly.

Limited Temperature Range

While suitable for many applications, the temperature limits of PTFE (260°C) and silicone (200°C) are not infinite. Exceeding these thresholds can cause the material to break down rapidly, releasing contaminants and causing system leaks.

Inherent Gas Permeability

Even a brand-new septum can exhibit some level of gas permeability. This can be a concern when working with highly volatile samples or when trying to maintain a specific gaseous environment within a vial, as diffusion can occur through the material itself.

A Proactive Approach to Septa Management

Treating septa as a critical consumable with a finite life is the best strategy for preventing analytical failure. Your approach should be based on the sensitivity of your work.

- If your primary focus is routine analysis with stable compounds: Implement a policy of regular visual inspection and scheduled replacement to avoid obvious failures.

- If your primary focus is trace analysis or volatile samples: Do not rely on visual inspection. Treat septa as a single-use or limited-use item with a strict, non-negotiable replacement schedule.

- If your primary focus is preventing contamination: Always use fresh septa from a sealed, recently opened package to minimize exposure to atmospheric contaminants prior to use.

Proactive management of your septa is a simple yet powerful step in guaranteeing the quality and reliability of your laboratory's output.

Summary Table:

| Concern | Consequence | Preventive Action |

|---|---|---|

| Loss of Silicone Elasticity | Failed seal, sample evaporation/contamination | Regular visual inspection and scheduled replacement |

| Exceeding Temperature Limits | Rapid material breakdown, system leaks | Adhere to PTFE (260°C) and silicone (200°C) limits |

| Inherent Gas Permeability | Diffusion of volatile samples/gases | Use fresh septa for trace analysis or volatile samples |

Ensure the integrity of your sensitive analyses with high-precision PTFE/silicone septa from KINTEK.

Don't let a degraded septum compromise your results and waste valuable resources. KINTEK specializes in manufacturing reliable PTFE components, including septa, for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact us today to discuss your application needs and discover how our seals can enhance the accuracy and reliability of your work.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application