For sensitive analytical work, PTFE-lined vials are an excellent choice, primarily compatible with Gas Chromatography (GC) and High-Performance Liquid Chromatography (HPLC). Their exceptional chemical inertness ensures that the vial and its cap liner do not react with or contaminate the sample, which is critical for obtaining accurate and reproducible results.

The core reason PTFE-lined vials are trusted for sensitive techniques is their chemical inertness. This single property minimizes the risk of sample contamination and interaction with the container, ensuring the integrity of trace-level analysis.

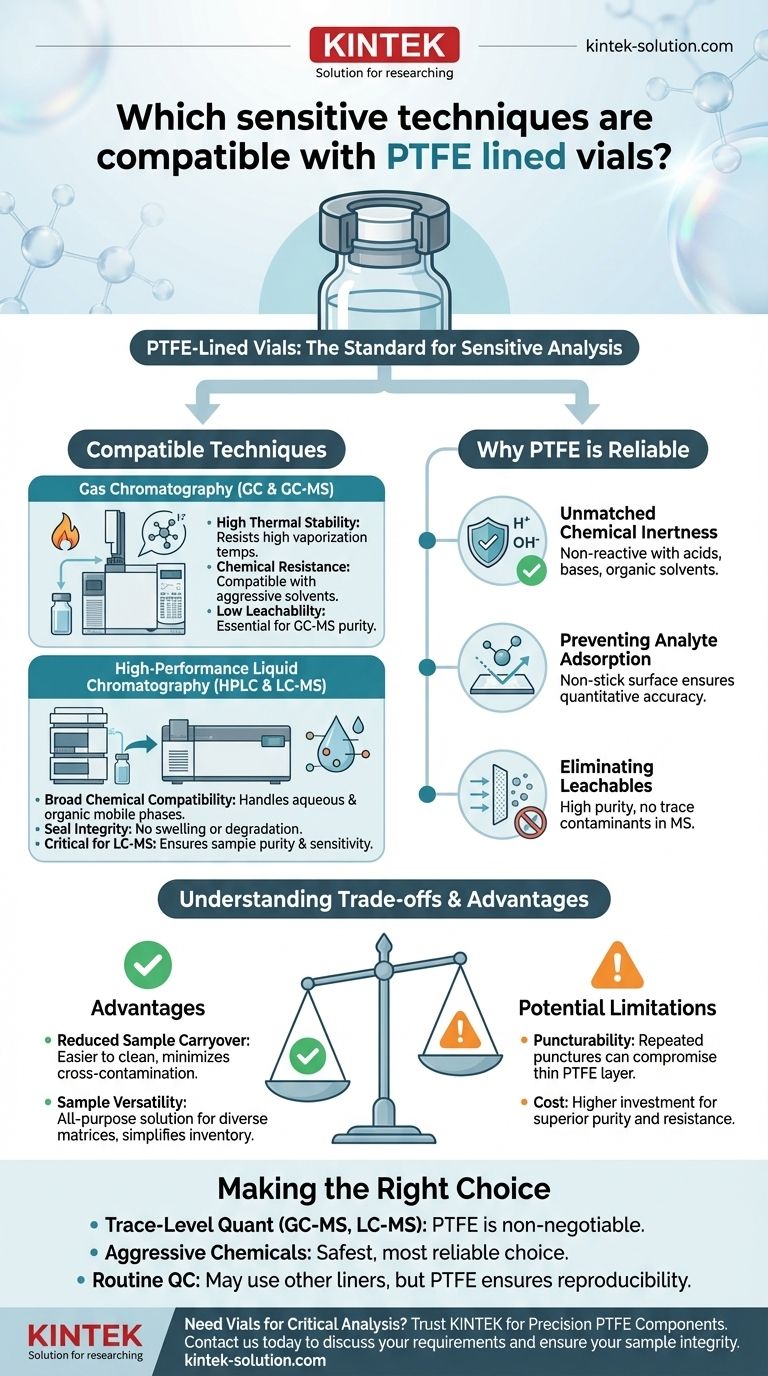

Why PTFE is a Standard for Sensitive Analysis

To understand which techniques are compatible with PTFE, we must first understand the properties that make it so reliable. Its value comes from creating an ultraclean, non-reactive environment for the sample.

Unmatched Chemical Inertness

PTFE is virtually non-reactive with nearly all common laboratory chemicals. This includes strong acids, bases, and a wide range of organic solvents. This broad compatibility makes it a safe choice for diverse sample types without risk of liner degradation or sample alteration.

Preventing Analyte Adsorption

The non-stick surface of PTFE is critical for quantitative analysis. It prevents active analytes, especially at low concentrations, from adsorbing (sticking) to the liner surface. This ensures the entire sample is available for injection and measurement.

Eliminating Leachables and Extractables

Sensitive detectors, like those used in mass spectrometry (MS), can detect contaminants in parts-per-billion or even lower concentrations. PTFE is a highly pure material that does not "leach" contaminants into the sample, preserving the purity of the analysis.

Compatible Techniques in Detail

The properties of PTFE make it the default choice for the industry's most common and sensitive analytical techniques.

Gas Chromatography (GC and GC-MS)

In GC, samples are vaporized at high temperatures. PTFE's thermal stability and chemical resistance to the aggressive solvents often used for sample preparation make it ideal. For Gas Chromatography-Mass Spectrometry (GC-MS), its low-leachability is paramount to avoid extraneous peaks in the chromatogram.

High-Performance Liquid Chromatography (HPLC and LC-MS)

HPLC relies on a wide variety of mobile phases, from aqueous buffers to pure organic solvents. The robust chemical compatibility of a PTFE liner ensures it will not swell, shrink, or degrade, maintaining a perfect seal. This is especially critical for Liquid Chromatography-Mass Spectrometry (LC-MS), where sample purity directly impacts sensitivity and accuracy.

Understanding the Trade-offs and Advantages

While highly effective, it's important to understand both the benefits and the practical limitations of using PTFE-lined vials.

Advantage: Reduced Sample Carryover

The non-stick properties of PTFE make vials and caps easier to clean effectively. More importantly, it reduces the risk of carryover, where trace amounts of a previous sample remain and contaminate the next one, a major concern in high-throughput labs.

Advantage: Sample Versatility

For laboratories that handle a wide variety of sample matrices, standardizing on PTFE-lined vials simplifies inventory. It provides a reliable, all-purpose solution that can handle almost any sample thrown its way.

Potential Limitation: Puncturability

The PTFE layer on a cap's septum is very thin. While excellent for creating an inert barrier, repeated punctures by an autosampler needle in the same spot can compromise its integrity. This can potentially expose the sample to the less-inert silicone backing of the septum.

Potential Limitation: Cost

Compared to other liner materials like red rubber or basic polyethylene, PTFE-lined caps are generally more expensive. This cost is a direct trade-off for the superior chemical resistance and purity required for sensitive analysis.

Making the Right Choice for Your Analysis

Your choice of vial and cap liner should be directly tied to the sensitivity and demands of your analytical method.

- If your primary focus is trace-level quantification (e.g., environmental analysis via GC-MS or LC-MS): PTFE-lined vials are the non-negotiable standard for ensuring data integrity.

- If your primary focus is working with aggressive chemicals or unknown samples: The broad chemical compatibility of PTFE provides the safest and most reliable choice to protect both your sample and your instrument.

- If your primary focus is routine QC with high-concentration samples and mild solvents: You may be able to use a more economical liner, but PTFE remains the superior option for guaranteeing reproducibility.

Ultimately, selecting the correct vial is a foundational step in generating reliable and defensible analytical data.

Summary Table:

| Technique | Key Compatibility Reason |

|---|---|

| Gas Chromatography (GC/GC-MS) | High thermal stability, resists aggressive solvents, prevents contamination. |

| HPLC & LC-MS | Broad chemical compatibility with aqueous and organic mobile phases, maintains seal integrity. |

| Trace-Level Analysis | Non-stick surface prevents analyte adsorption, ensuring quantitative accuracy. |

Need Vials for Critical Analysis? Trust KINTEK for Precision PTFE Components.

Generating reliable data starts with the right consumables. KINTEK manufactures high-purity PTFE components—including seals, liners, and labware—specifically for demanding applications in semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your sensitive techniques.

Contact us today to discuss your requirements and ensure your sample integrity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the characteristics of wide mouth PTFE laboratory bottles? Engineered for Extreme Chemical & Thermal Resistance

- What are the benefits of reusing HPLC autosampler vials with PTFE/silicone septa? Save Costs & Boost Lab Sustainability

- What are the advantages of PTFE shovels in terms of chemical resistance? Unmatched Inertness for Handling Corrosives

- What other PTFE lab accessories are commonly used? Essential Tools for Chemical Resistance & Purity

- What are the applications of PTFE-lined bottle caps? Ensure Ultimate Purity and Chemical Resistance

- What are the benefits of silicone/PTFE liners? Ensure Unmatched Sample Purity and Integrity

- What are PTFE stirring shafts and what styles are available? Select the Right Impeller for Your Lab

- What are the key properties of PTFE syringe filters? Unlock Unmatched Chemical Resistance and Versatility