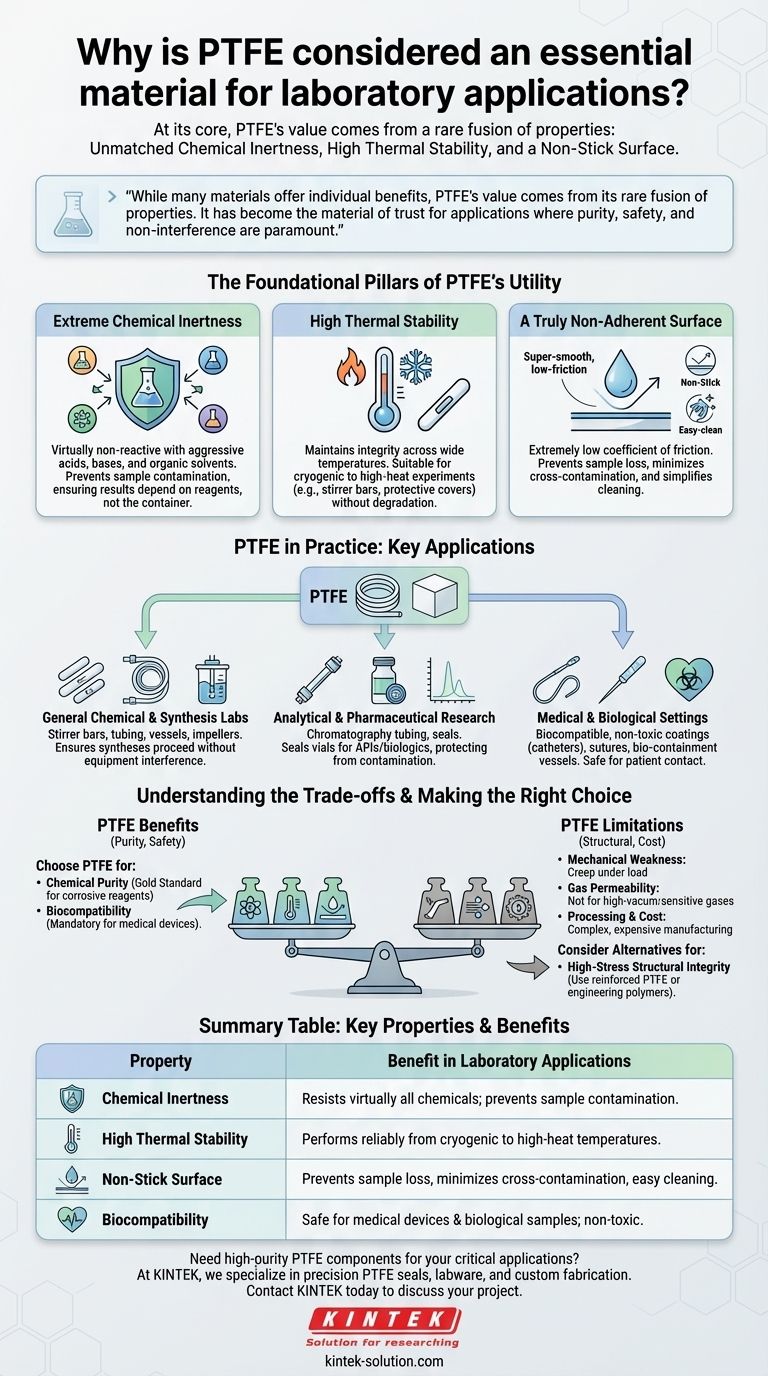

At its core, Polytetrafluoroethylene (PTFE) is considered an essential material in laboratory settings because of its unmatched chemical inertness, high thermal stability, and non-stick surface. This unique combination ensures that the material itself does not react with, contaminate, or adhere to the sensitive substances being studied, thereby preserving the integrity of experimental results.

While many materials offer individual benefits, PTFE’s value comes from its rare fusion of properties. It has become the material of trust for applications where purity, safety, and non-interference are paramount.

The Foundational Pillars of PTFE's Utility

To understand why PTFE is so ubiquitous, we must look at its three core characteristics. These properties work in concert to solve the most common challenges faced in a laboratory environment.

Extreme Chemical Inertness

PTFE is virtually non-reactive with the vast majority of chemicals, including aggressive acids, bases, and organic solvents.

This inertness is critical because it prevents the PTFE equipment from leaching contaminants into a sample or reacting with the substances it holds. This ensures that the results of an experiment are due to the reagents, not the container.

High Thermal Stability

The material maintains its structural integrity and chemical properties across a wide temperature range, making it suitable for both cryogenic applications and high-temperature experiments.

This allows for its use in equipment like stirrer bars and protective covers that are subjected to direct heating without risk of melting or degradation.

A Truly Non-Adherent Surface

PTFE has an extremely low coefficient of friction, creating a non-stick surface that is difficult for other substances to adhere to.

This property is invaluable for preventing sample loss, minimizing cross-contamination between experiments, and simplifying the cleaning of labware.

PTFE in Practice: Key Applications

The theoretical benefits of PTFE translate directly into practical, everyday use across various scientific disciplines. Its versatility allows it to be shaped into everything from simple tubing to complex medical components.

General Chemical and Synthesis Labs

In standard chemical labs, you will find PTFE in stirrer bars, tubing, vessels, and impellers. Its non-reactive nature ensures that chemical syntheses proceed without interference from the equipment itself.

Analytical and Pharmaceutical Research

For high-precision fields like chromatography (GC and HPLC), PTFE is used for tubing and seals. In pharmaceutical work, it is vital for sealing vials containing valuable Active Pharmaceutical Ingredients (APIs) or biologics, protecting them from contamination.

Medical and Biological Settings

PTFE is fundamentally biocompatible, non-toxic, and inert within the human body. It does not cause adverse tissue reactions, making it a cornerstone material for medical devices.

It is used as a coating on catheters to prevent bacterial adhesion, as a material for surgical sutures, and in the construction of syringes and life-saving bio-containment vessels.

Understanding the Trade-offs

No material is perfect, and a complete technical understanding requires acknowledging PTFE's limitations. These trade-offs are critical when selecting materials for a specific application.

Mechanical Weakness

PTFE is a relatively soft polymer. Under sustained pressure or load, it can be susceptible to "creep," where the material slowly deforms over time. It is not suitable for high-load, structural applications without reinforcement.

Gas Permeability

While excellent as a barrier for liquids, PTFE can be permeable to certain small gas molecules. This can be a disqualifying factor in high-vacuum systems or when working with highly sensitive gases.

Processing and Cost

PTFE cannot be processed using conventional melt-extrusion or injection molding techniques, which makes manufacturing more complex and expensive compared to other polymers. This can influence the cost and availability of custom or intricate parts.

Making the Right Choice for Your Application

To select the right material, you must align its properties with your primary experimental or clinical objective.

- If your primary focus is chemical purity and non-reactivity: PTFE is the gold standard for handling corrosive reagents, high-purity solvents, or sensitive biological samples.

- If your primary focus is biocompatibility and patient safety: Its inert and non-toxic nature makes it a mandatory consideration for medical devices, implants, and fluid pathways.

- If your primary focus is high-stress structural integrity: You may need to consider alternative engineering polymers or reinforced PTFE, as its softness is a key limitation.

Ultimately, choosing PTFE is a decision to prioritize reliability, safety, and the integrity of your work.

Summary Table:

| Property | Benefit in Laboratory Applications |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents; prevents sample contamination. |

| High Thermal Stability | Performs reliably from cryogenic temperatures to high-heat experiments. |

| Non-Stick Surface | Prevents sample loss, minimizes cross-contamination, and allows for easy cleaning. |

| Biocompatibility | Safe for medical devices and biological samples; non-toxic and inert. |

Need high-purity PTFE components for your critical applications?

At KINTEK, we specialize in the precision manufacturing of PTFE seals, liners, labware, and custom components. Whether you're in the semiconductor, medical, pharmaceutical, or industrial sector, our expertise ensures your equipment meets the highest standards of chemical resistance and purity.

We offer custom fabrication from prototypes to high-volume orders, guaranteeing a perfect fit for your unique requirements.

Contact KINTEK today to discuss your project and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance