At its core, the gas permeability of PTFE/silicone septa creates a critical vulnerability in analytical chemistry. This property allows gases to diffuse through the material, which can lead to the loss of volatile sample components and disrupt the controlled gas environment within a vial, ultimately compromising the accuracy and reliability of your results.

The fundamental issue is a trade-off between physical performance and chemical integrity. The silicone provides excellent resealability after puncture, but its inherent permeability risks altering the very sample you are trying to preserve and measure.

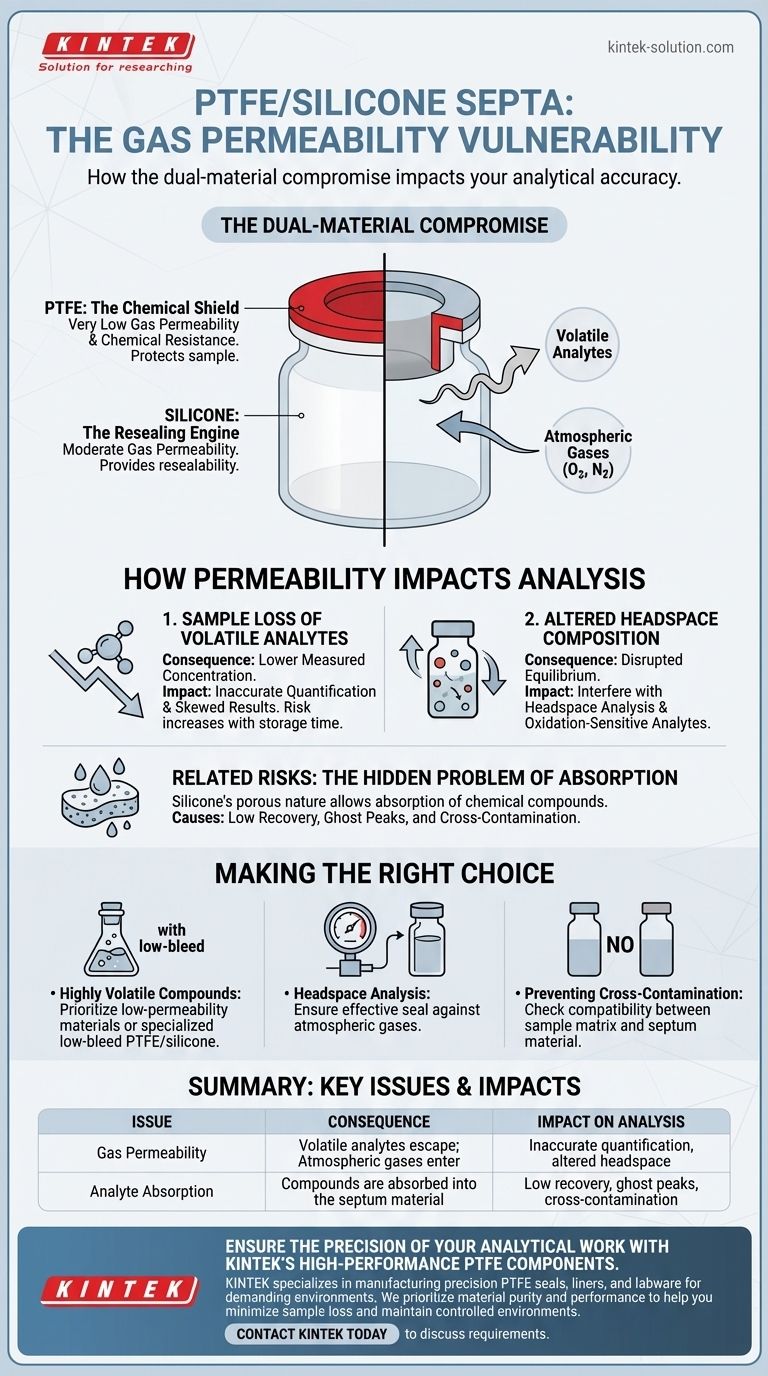

The Dual-Material Compromise

Septa are not monolithic; the common PTFE/silicone construction is a layered design where each material serves a distinct purpose. Understanding this design reveals the source of the permeability problem.

The Role of PTFE: The Chemical Shield

The thin layer of PTFE (polytetrafluoroethylene) faces the sample. Its primary job is to provide a chemically inert barrier.

PTFE has very low gas permeability and excellent chemical resistance, effectively protecting the sample from contamination and preventing it from interacting with the silicone layer.

The Role of Silicone: The Resealing Engine

The much thicker silicone layer provides the mechanical properties of the septum. It is soft and elastic, allowing it to reseal tightly after a needle pierces it.

However, silicone has moderate gas permeability. While it excels at physical sealing, it is not a perfect gas barrier.

How Permeability Impacts Your Analysis

The consequence of silicone's permeability is that gases can slowly diffuse in or out of the sample vial over time. This leads to two significant problems.

Sample Loss of Volatile Analytes

The most direct impact is the loss of your sample. Volatile organic compounds (VOCs) or other gaseous analytes can escape directly through the septum.

This leads to a lower measured concentration than is actually present, causing inaccurate quantification and skewed results. The longer the sample is stored, the greater the potential for loss.

Altered Headspace Composition

For techniques like headspace analysis, the gas composition and pressure above the sample are critical. Permeability can ruin this delicate equilibrium.

Atmospheric gases (like oxygen or nitrogen) can diffuse into the vial, while internal gases can escape. This alters the partial pressures and can interfere with the analysis, especially if the target analytes are sensitive to oxidation.

Key Trade-offs and Related Risks

Choosing the right septum requires balancing competing needs. The permeability issue is often linked to another common problem: absorption.

The Hidden Risk of Absorption

Silicone's porous nature not only allows gas transfer but can also lead to the absorption of certain chemical compounds from your sample.

This can cause two problems: the loss of analyte into the septum material (leading to low recovery) and the potential for the absorbed compound to desorb during a later analysis, creating "ghost peaks" and cross-contamination.

Material Selection is Critical

There is no single "best" septum. The choice depends entirely on the application.

For highly volatile samples or trace analysis, a septum with the lowest possible permeability is essential. For routine analyses of non-volatile compounds, a standard PTFE/silicone septum may be perfectly adequate and cost-effective.

Making the Right Choice for Your Goal

To mitigate these issues, align your septum choice with your specific analytical requirements.

- If your primary focus is analyzing highly volatile compounds: Prioritize septa made with lower-permeability materials or specialized low-bleed PTFE/silicone formulations to minimize sample loss.

- If your primary focus is headspace analysis: Ensure your chosen septum provides an effective seal against atmospheric gases to maintain the integrity of the vial's internal environment.

- If your primary focus is preventing cross-contamination: Always check for compatibility between your sample matrix and the septum material to avoid analyte absorption.

Ultimately, selecting the appropriate septum is a critical step in ensuring the precision and validity of your analytical work.

Summary Table:

| Issue | Consequence | Impact on Analysis |

|---|---|---|

| Gas Permeability | Volatile analytes escape; atmospheric gases enter | Inaccurate quantification, altered headspace |

| Analyte Absorption | Compounds are absorbed into the septum material | Low recovery, ghost peaks, cross-contamination |

Ensure the precision of your analytical work with KINTEK's high-performance PTFE components.

Gas permeability and analyte absorption in septa can compromise your sample integrity and lead to inaccurate results. KINTECH specializes in manufacturing precision PTFE seals, liners, and labware designed for the demanding environments of semiconductor, medical, laboratory, and industrial applications. We prioritize material purity and performance to help you minimize sample loss and maintain controlled environments.

Whether you need standard components or custom-fabricated solutions—from prototypes to high-volume orders—we deliver the reliability your lab depends on.

Contact KINTEK today to discuss your specific requirements and find the perfect sealing solution for your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability