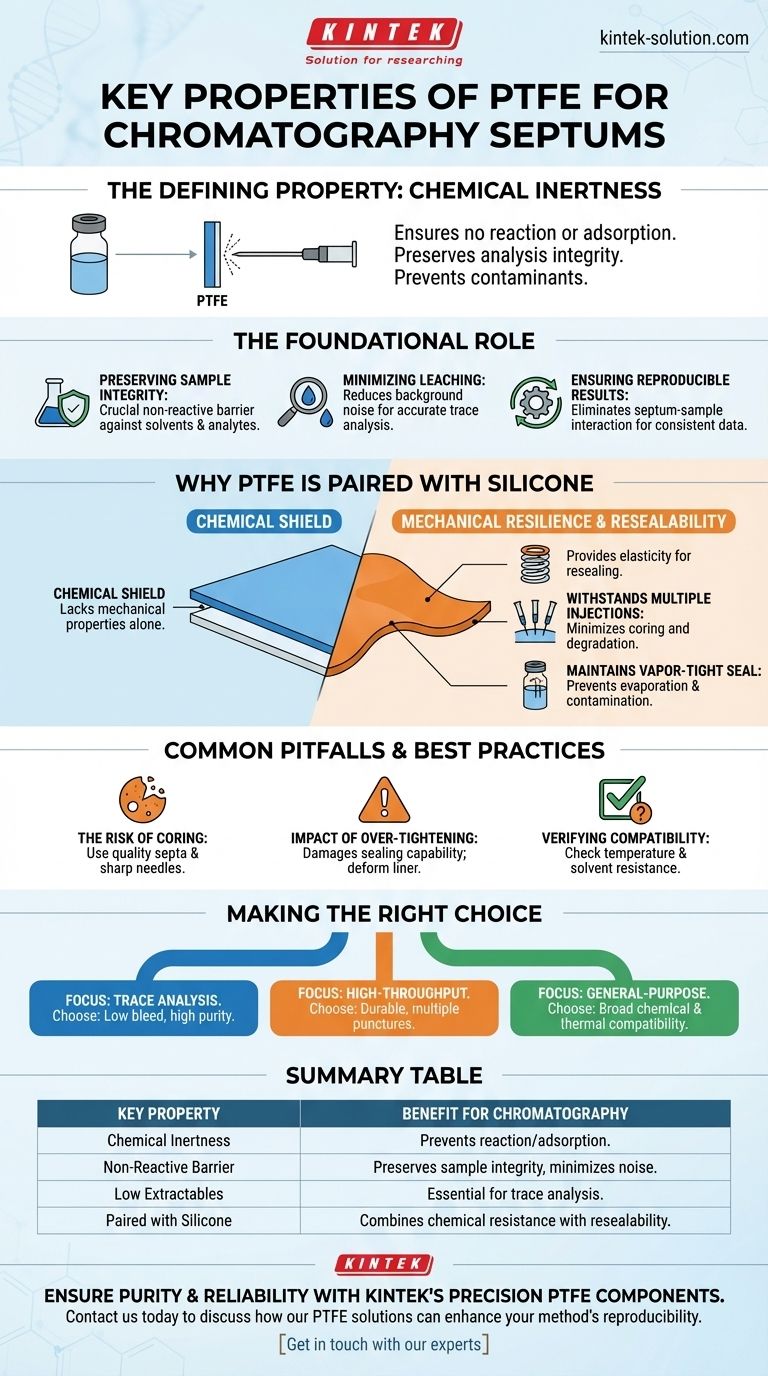

The defining property of PTFE for chromatography septums is its exceptional chemical inertness. This characteristic ensures the septum does not react with or adsorb the sample, thereby preserving the integrity of the analysis and preventing the introduction of contaminants that could skew results.

The core function of PTFE in a septum is to act as a chemically inert barrier between the sample and the resealing material (usually silicone). This combination delivers the chemical resistance of PTFE with the mechanical durability and resealability required for reliable, repeatable injections.

The Foundational Role of PTFE's Chemical Inertness

The primary goal in chromatography is to analyze the sample, not the sample plus anything that has leached from your consumables. PTFE's unique chemical properties make it the ideal first line of defense.

Preserving Sample Integrity

Because PTFE is highly non-reactive, it provides a crucial barrier that prevents any interaction with the solvents or analytes in your sample. This ensures that what you inject is exactly what you intended to analyze.

Minimizing Leaching and Extractables

A key concern, especially in trace analysis, is the risk of materials "leaching" from the septum into the sample. PTFE's inertness minimizes this risk, reducing background noise and ensuring that low-concentration components can be accurately detected and quantified.

Ensuring Reproducible Results

By eliminating the variable of septum-sample interaction, PTFE contributes directly to the consistency and reproducibility of your results. This reliability is the cornerstone of any valid analytical method.

Why PTFE is Almost Always Paired with Silicone

While PTFE provides the chemical shield, it lacks the mechanical properties needed for a functional septum on its own. The combination with silicone creates a composite material that meets all the demands of modern chromatography.

The Need for Mechanical Resilience

Silicone provides the elasticity and "springiness" that PTFE lacks. After the needle is withdrawn, the flexible silicone layer expands to reseal the puncture, maintaining the vial's seal.

Enabling Multiple Injections

The robustness of the silicone backing allows the septum to withstand numerous punctures from an autosampler needle without significant degradation or "coring" (shedding particles into the vial). This durability is essential for high-throughput labs to minimize instrument downtime.

Maintaining a Vapor-Tight Seal

The combination of materials ensures the vial remains properly sealed before and after injection. This prevents sample evaporation, protects the sample from atmospheric contamination, and maintains pressure within the vial, which is critical for many GC applications.

Common Pitfalls and Best Practices

Even with the best materials, improper use can compromise results. Understanding the limitations and proper handling is key to maximizing performance.

The Risk of Coring

Coring occurs when the needle punches out a small piece of the septum, which then falls into the sample. Using a high-quality septum and sharp, appropriate-gauge needles minimizes this risk.

The Impact of Over-tightening

Over-tightening the vial cap can deform or even puncture the septum liner before an injection ever occurs. This damages its sealing capability and can lead to evaporation or contamination. The cap should be firm but not excessively tight.

Verifying Application Compatibility

While PTFE/silicone is highly versatile, you must still verify its compatibility with your specific application. Ensure the septum's temperature range is suitable for your instrument's inlet temperature and that it is resistant to the specific solvents you are using.

Making the Right Choice for Your Analysis

Your analytical goal should guide your choice of septum.

- If your primary focus is trace analysis: Prioritize septa specifically rated for low bleed and high purity to prevent any risk of sample contamination from extractables.

- If your primary focus is high-throughput automation: Select a durable PTFE/silicone septum designed to withstand hundreds of punctures without failure to ensure long, uninterrupted runs.

- If your primary focus is general-purpose use with diverse solvents: Choose a septum with broad chemical and thermal compatibility to provide reliable performance across a wide range of methods.

Ultimately, selecting the correct septum is a critical step in building a robust and reliable analytical method.

Summary Table:

| Key Property | Benefit for Chromatography |

|---|---|

| Chemical Inertness | Prevents reaction with or adsorption of samples/analytes. |

| Non-Reactive Barrier | Preserves sample integrity and minimizes background noise. |

| Low Extractables | Essential for accurate trace analysis. |

| Paired with Silicone | Combines chemical resistance with mechanical resealability. |

Ensure the purity and reliability of your chromatography analyses with KINTEK's precision PTFE components.

As specialists in custom fabrication for the semiconductor, medical, and laboratory industries, we understand the critical need for chemically inert, high-performance materials. Our PTFE septums and components are manufactured to the highest standards of precision, ensuring they deliver the consistent barrier properties your sensitive applications demand—from prototype development to high-volume orders.

Contact us today to discuss how our PTFE solutions can enhance your method's reproducibility and protect your sample integrity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining