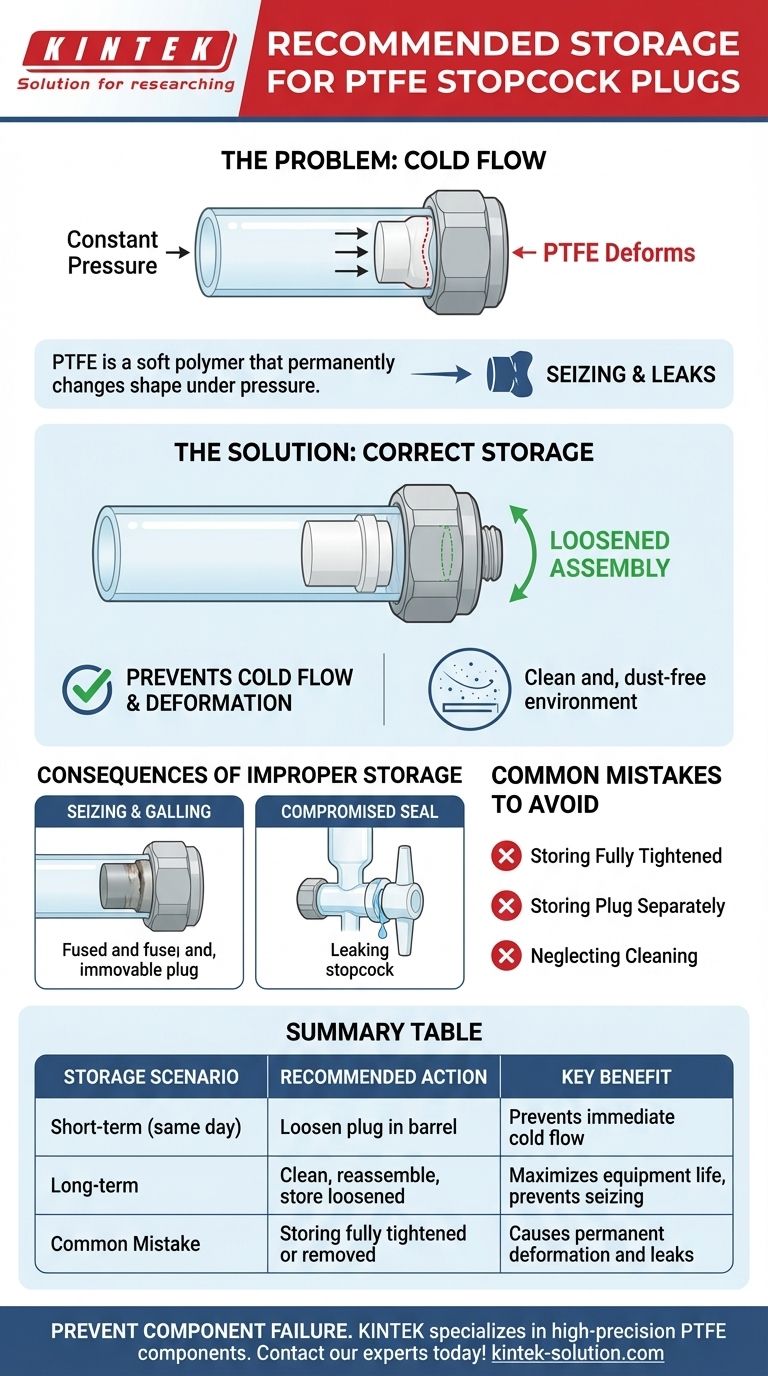

The recommended storage method for a PTFE stopcock plug is to keep it inside its matched glass barrel, but with the retaining nut and plug loosened significantly. This assembly should then be stored in a clean, dust-free environment to prevent contamination.

The core issue is the physical nature of PTFE plastic versus glass. Because PTFE is a soft material that deforms under sustained pressure—a phenomenon known as "cold flow"—leaving it tightly seated will cause it to permanently change shape, leading to seizing and leaks.

Understanding the Material Interaction

The correct storage procedure is a direct consequence of the physical properties of the two materials involved. Understanding this interaction is key to preserving your laboratory glassware.

The Pliability of PTFE

PTFE (Polytetrafluoroethylene) is prized for its chemical inertness and low-friction surface. However, it is also a relatively soft polymer.

Under constant pressure, even at room temperature, PTFE will slowly deform to match the shape of the harder surface it's pressed against. This process is often called cold flow or creep.

The Rigidity of Glass

The stopcock barrel, typically made of borosilicate glass, is extremely hard and rigid. Its shape is fixed.

When you tighten the PTFE plug, you are compressing the soft plug against this unyielding glass form.

The Consequences of Improper Storage

Leaving a PTFE stopcock fully tightened during storage is the primary cause of its failure. The constant pressure forces the PTFE to deform in ways that permanently compromise its function.

Seizing and Galling

Over time, the cold flow causes the PTFE to expand into the bore holes of the stopcock barrel.

When you later attempt to turn the plug, this deformed material will catch and bind, causing the stopcock to seize. Applying excessive force to a seized plug is a common cause of glassware breakage.

Compromised Seal Integrity

This deformation is permanent. The plug will no longer have the perfectly smooth, tapered surface required to form a leak-proof seal when re-tightened.

This can result in persistent, frustrating leaks that render the burette, separatory funnel, or chromatography column unusable for precise work.

Common Mistakes to Avoid

To ensure the longevity and reliability of your equipment, avoid these frequent errors.

Storing While Fully Tightened

This is the most critical mistake. Any storage period, from overnight to long-term, is enough to initiate cold flow and risk permanent deformation.

Storing the Plug Separately

Removing the plug from the barrel entirely is also poor practice. It exposes the delicate, precision-machined surface of the plug to scratches and contamination.

Furthermore, it risks mismatching plugs and barrels. Since they are often ground as a matched set, using a different plug will likely result in a poor seal.

Neglecting to Clean Before Storage

Always clean and dry the stopcock components before storage. Chemical residues can crystallize or solidify, acting like an adhesive that contributes to seizing.

A Simple Rule for Stopcock Longevity

Use this guidance to determine the right action for your equipment.

- If your primary focus is quick, short-term storage (e.g., between uses on the same day): Loosening the plug is sufficient to prevent immediate issues.

- If your primary focus is long-term storage or maximizing equipment life: Always clean the components, then reassemble and store them with the plug loosened in a dust-free cabinet.

- If you encounter a seized stopcock: Never apply excessive force. Gentle, uniform warming of the barrel can sometimes help, but be prepared that the plug may already be permanently damaged.

Adopting this simple habit of loosening the plug before storage is the single most effective way to protect the function and value of your laboratory glassware.

Summary Table:

| Storage Scenario | Recommended Action | Key Benefit |

|---|---|---|

| Short-term (same day) | Loosen plug in barrel | Prevents immediate cold flow |

| Long-term | Clean, reassemble, and store with plug loosened | Maximizes equipment life and prevents seizing |

| Common Mistake | Storing fully tightened or plug removed | Causes permanent deformation and leaks |

Are your PTFE components failing prematurely? KINTEK specializes in manufacturing high-precision, durable PTFE components—including custom stopcock plugs, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in material science ensures components that resist cold flow and maintain integrity. From prototypes to high-volume orders, we deliver reliability. Protect your investment and eliminate downtime—contact our experts today for a custom solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications