When selecting a PTFE-lined bottle cap, the primary liner options are not just different types of PTFE, but different constructions that leverage its properties. The main configurations are solid PTFE liners and composite liners, most commonly PTFE-faced silicone, which combine the chemical inertness of PTFE with the sealing capabilities of other materials.

The core decision is not simply about choosing PTFE, but about how it is integrated into the liner. You must choose between the absolute purity of a solid PTFE liner and the superior sealing performance of a PTFE-faced composite liner.

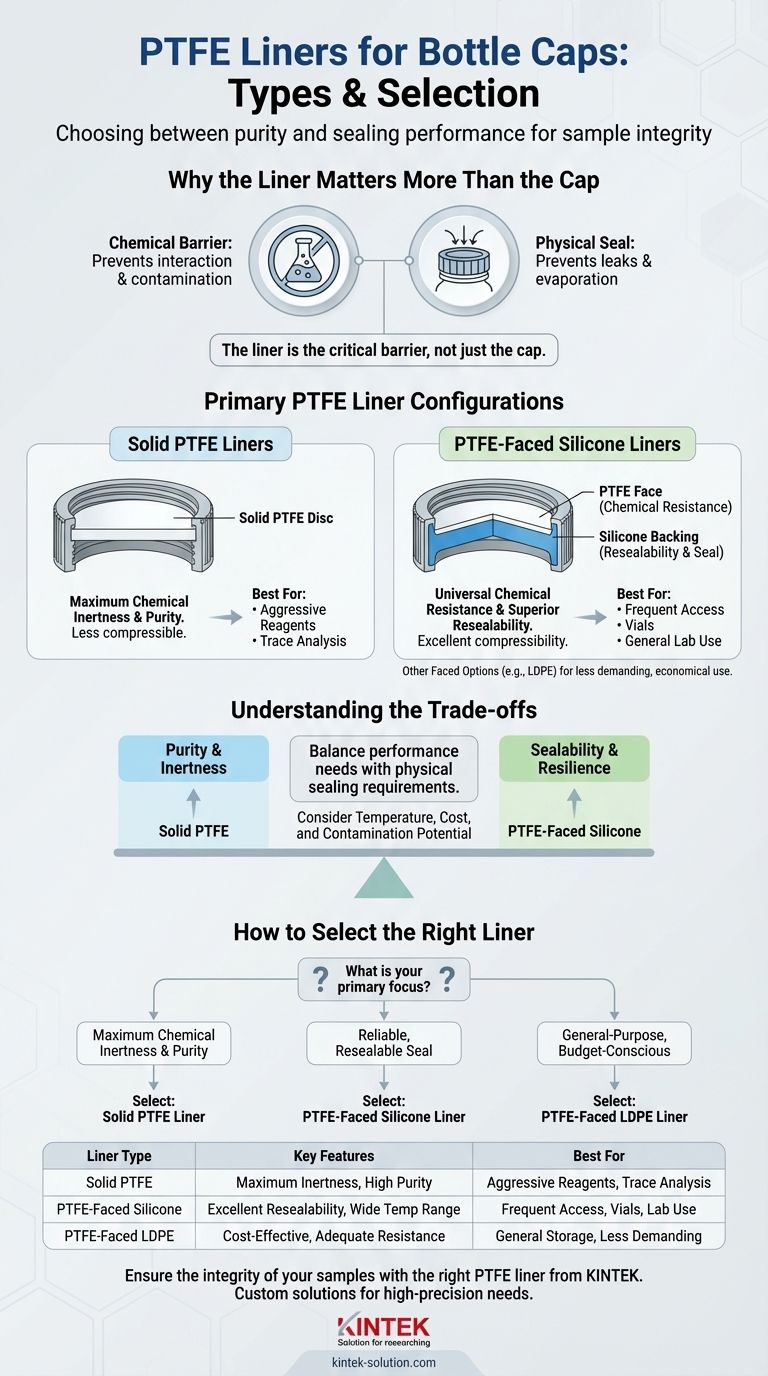

Why the Liner Matters More Than the Cap

A bottle cap's primary function is to provide a secure seal, but the liner is what truly protects the contents. The cap itself, typically made of polypropylene, offers structural integrity, while the liner provides the critical barrier.

The Role of the Chemical Barrier

The liner is the only part of the cap assembly that comes into direct contact with the bottle's contents.

Its job is to be completely non-reactive, preventing any interaction, contamination, or degradation of the sample or chemical being stored.

The Function of the Physical Seal

The liner must also be compliant enough to press firmly against the rim of the container.

This creates an airtight seal that prevents leaks, evaporation, and exposure to the outside atmosphere, ensuring sample integrity.

The Primary PTFE Liner Configurations

The term "PTFE liner" most often refers to a composite design. Understanding the two main approaches is key to making the correct choice.

PTFE-Faced Silicone Liners

This is the most common and versatile configuration. A thin layer of PTFE is bonded to a thicker, softer backing of silicone.

This design offers the best of both worlds: the PTFE face provides the universal chemical resistance, while the compressible silicone provides outstanding resealability and a tight, reliable seal even after multiple punctures or uses.

Solid PTFE Liners

In this case, the entire liner is a solid disc of pure PTFE. This offers the highest possible chemical inertness and purity.

Because PTFE is a relatively rigid material, these liners are less compressible and may not provide as forgiving a seal as composite liners, especially on containers with minor rim imperfections.

Other Faced Options (e.g., LDPE)

For less demanding applications, LDPE (Low-Density Polyethylene) can be used as a backing material instead of silicone.

PTFE-faced LDPE is a more economical choice, but it has a much narrower temperature range and lower chemical resistance compared to a silicone backing.

Understanding the Trade-offs

Choosing the right liner requires balancing performance needs with physical sealing requirements. No single option is perfect for every scenario.

Purity vs. Sealability

A solid PTFE liner offers the ultimate defense against chemical attack and potential contamination from backing materials.

However, a PTFE-faced silicone liner provides a vastly superior physical seal, is better for repeated access, and is more tolerant of slight imperfections in the container rim.

Performance vs. Cost

Silicone is an exceptional backing material due to its wide temperature tolerance (-200°C to +250°C), chemical resilience, and excellent compressibility. This makes it ideal for lab, pharma, and autoclavable applications.

LDPE is a cost-effective alternative for general-purpose storage where extreme temperatures and aggressive solvents are not a concern.

Contamination Potential

While PTFE itself is exceptionally inert, in ultra-sensitive applications, one must consider potential extractables from the backing material (silicone or LDPE) or any adhesives used to bond the layers. For most uses, this is negligible, but for high-purity trace analysis, a solid PTFE liner eliminates this variable.

How to Select the Right Liner

Your choice should be dictated entirely by the demands of your application.

- If your primary focus is maximum chemical inertness and purity: A solid PTFE liner is the most direct and uncompromising choice, especially for storing aggressive reagents.

- If your primary focus is a reliable, resealable seal for repeated access: A PTFE-faced silicone liner offers the best balance of chemical resistance and physical compressibility for vials and frequent-use containers.

- If your primary focus is general-purpose chemical storage on a budget: A PTFE-faced LDPE liner provides adequate protection for many common, less-demanding applications.

By matching the liner's specific construction to your application's demands, you ensure the complete integrity of your work.

Summary Table:

| Liner Type | Key Features | Best For |

|---|---|---|

| Solid PTFE | Maximum chemical inertness, high purity | Aggressive reagents, trace analysis, maximum purity needs |

| PTFE-Faced Silicone | Excellent resealability, wide temperature range, reliable seal | Frequent access, vials, general lab use, autoclavable applications |

| PTFE-Faced LDPE | Cost-effective, adequate chemical resistance | General-purpose storage, less demanding applications, budget-conscious use |

Ensure the integrity of your samples with the right PTFE liner from KINTEK.

Whether your priority is absolute chemical purity with a solid PTFE liner or a reliable, resealable seal with a PTFE-faced composite, KINTEK has the solution. We specialize in manufacturing high-precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get a liner perfectly matched to your container and application requirements.

Contact our experts today to discuss your specific needs and receive a custom solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are some specialized PTFE stirring bars available? Optimize Your Lab Mixing Efficiency

- What are the key features of PTFE reagent bottles? Superior Chemical Resistance and Durability

- What are some specific applications of PTFE shovels in the laboratory? Ensure Sample Purity and Safety

- How does the durability of PTFE vials contribute to cost savings? Lower Your Lab's Total Cost of Ownership

- What is PTFE and how is it used in vial caps? Ensure Sample Purity with Inert Liner Technology

- What are the key properties of Teflon membranes? Ensure Chemical Resistance and Sample Purity

- What issue arises from the gas permeability of PTFE/silicone septa? Protect Your Sample Integrity

- Why are PTFE filters advantageous for gravimetric analysis? Achieve Unmatched Accuracy and Precision