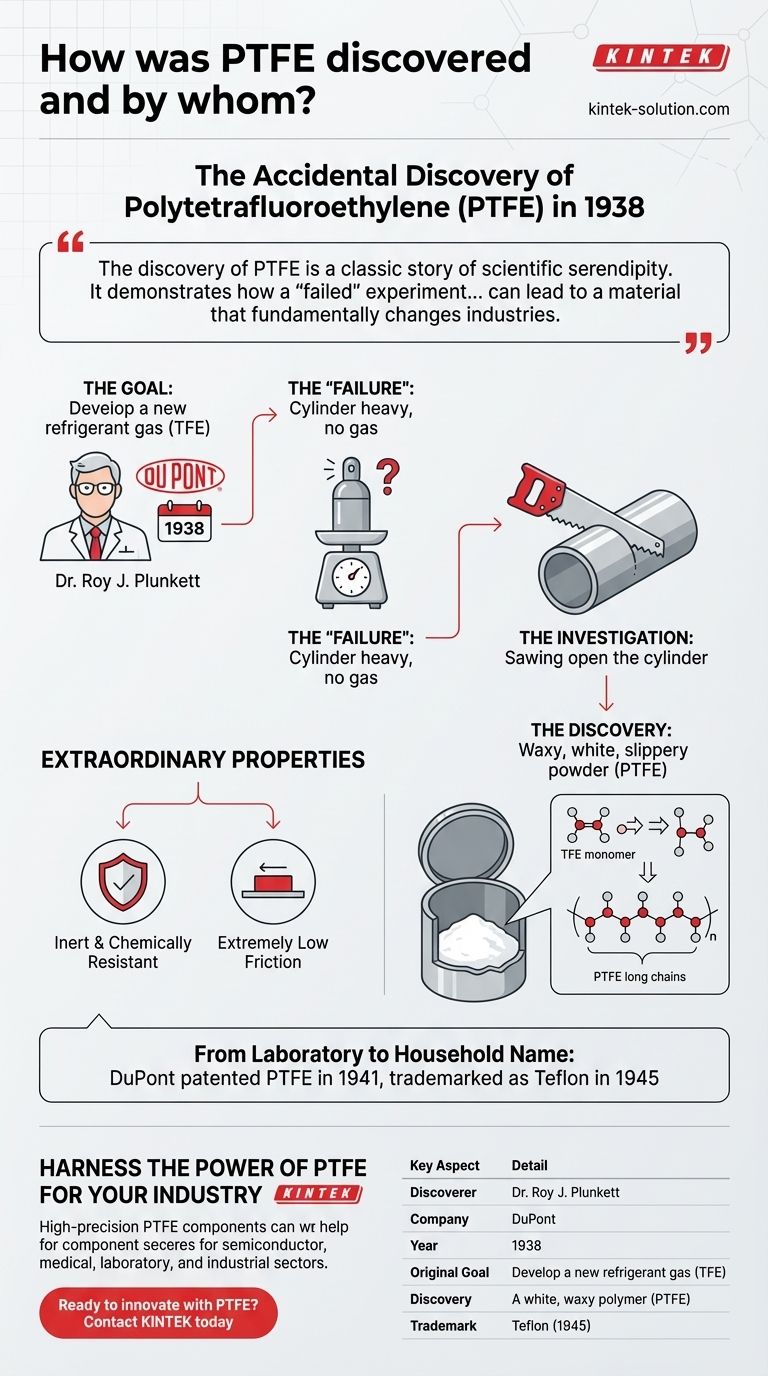

In short, Polytetrafluoroethylene (PTFE) was discovered entirely by accident in 1938. The discovery was made by a young chemist named Dr. Roy J. Plunkett while he was employed at the DuPont company. He was not trying to create a revolutionary polymer; his objective was to develop a new, non-toxic refrigerant gas.

The discovery of PTFE is a classic story of scientific serendipity. It demonstrates how a "failed" experiment, when met with curiosity and investigation, can lead to a material that fundamentally changes industries.

The Context of the Discovery

To understand the significance of this accident, it's important to know what Dr. Plunkett was trying to achieve and the environment in which he was working.

The Researcher and His Goal

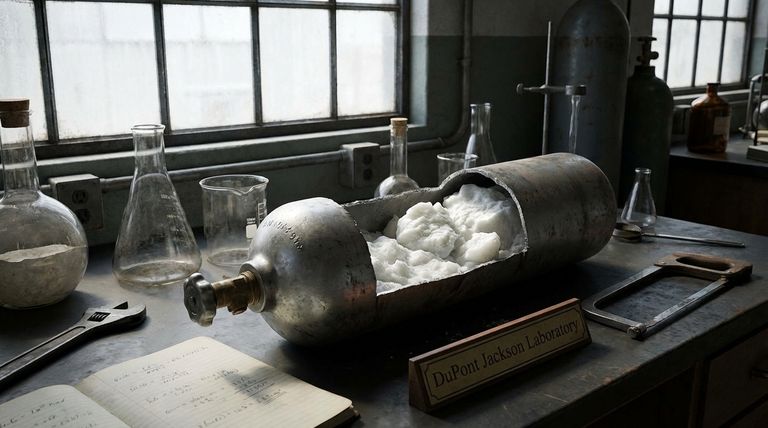

Dr. Roy J. Plunkett was a chemist at DuPont’s Jackson Laboratory in New Jersey. His project focused on finding a new chlorofluorocarbon (CFC) to be used as a refrigerant.

The Chemical at Hand

The specific gas Plunkett was experimenting with was tetrafluoroethylene (TFE). He had produced a significant amount of it and stored it in small, pressurized gas cylinders to be used in his experiments.

The Moment of Serendipity

The discovery was not the result of a successful experiment, but the investigation of a puzzling failure. It was Plunkett's decision to understand why it failed that led to the breakthrough.

A Cylinder That Weighed Too Much

Plunkett and his assistant opened the valve on a cylinder of TFE gas, but nothing came out. The cylinder's weight, however, indicated that it was still full of material. The expected gas was gone, but something was left inside.

The Decision to Investigate

Instead of discarding the seemingly faulty cylinder, Plunkett’s curiosity took over. He made the unconventional decision to saw the metal cylinder open to find out what had happened to the gas.

A Mysterious White Powder

Inside, he did not find gas. Instead, the cylinder was coated with a waxy, white, and remarkably slippery solid. The gaseous TFE molecules had bonded together—or polymerized—into a long-chain polymer. This new substance was polytetrafluoroethylene.

Understanding the New Material

The initial discovery was just the beginning. The truly remarkable part was what DuPont's scientists learned about the properties of this accidental substance.

Extraordinary Properties

The newly discovered PTFE was found to be incredibly inert, meaning it didn't react with virtually any other chemical, including highly corrosive acids. It also had an extremely low coefficient of friction, making it one of the most slippery materials known to science.

From Laboratory to Household Name

DuPont patented the substance in 1941 and registered the Teflon trademark in 1945. What started as a failed refrigerant experiment became the basis for non-stick cookware, low-friction coatings, and countless other industrial and medical applications.

The Lessons from an Accidental Discovery

The story of PTFE's origin holds key insights that are still relevant today in science and innovation.

- If your primary focus is scientific research: Recognize that an unexpected or failed result can be more valuable than the one you were seeking, provided you investigate it.

- If your primary focus is innovation: Understand that major breakthroughs often come from chance and being prepared to explore unforeseen opportunities, not just from a linear, predictable plan.

This single, accidental discovery of a strange white powder ultimately created an entirely new category of material science.

Summary Table:

| Key Aspect | Detail |

|---|---|

| Discoverer | Dr. Roy J. Plunkett |

| Company | DuPont |

| Year | 1938 |

| Original Goal | Develop a new refrigerant gas (TFE) |

| Discovery | A white, waxy polymer (PTFE) found inside a gas cylinder |

| Trademark | Teflon (registered 1945) |

Harness the Power of PTFE for Your Industry

The accidental discovery of PTFE unlocked a material with unparalleled chemical resistance and a low coefficient of friction. At KINTEK, we leverage this advanced polymer to manufacture high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

Whether you need reliable prototypes or high-volume production, our expertise in custom PTFE fabrication ensures your components meet the highest standards of performance and durability.

Ready to innovate with PTFE? Contact KINTEK today to discuss your specific requirements and discover how our precision components can enhance your applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- Why is PTFE suitable for high-temperature applications? Unlock Reliable Performance Up to 600°F

- What are the safety considerations when using PTFE at high temperatures? Managing Decomposition Risks

- What industries commonly use PTFE coatings besides cookware? Powering High-Tech Applications

- What are the limitations of PTFE? Understanding Creep, Abrasion, and Radiation Weaknesses

- What is PTFE commonly known as and what type of material is it? A Guide to High-Performance PTFE Properties

- What are the primary applications of PTFE in electrical and aerospace industries? Ensure Reliability in Extreme Environments

- How can PTFE properties be enhanced? Improve Wear, Strength, and Creep Resistance with Fillers

- How does ePTFE's porosity benefit its applications? Achieve Selective Permeability for Your Designs