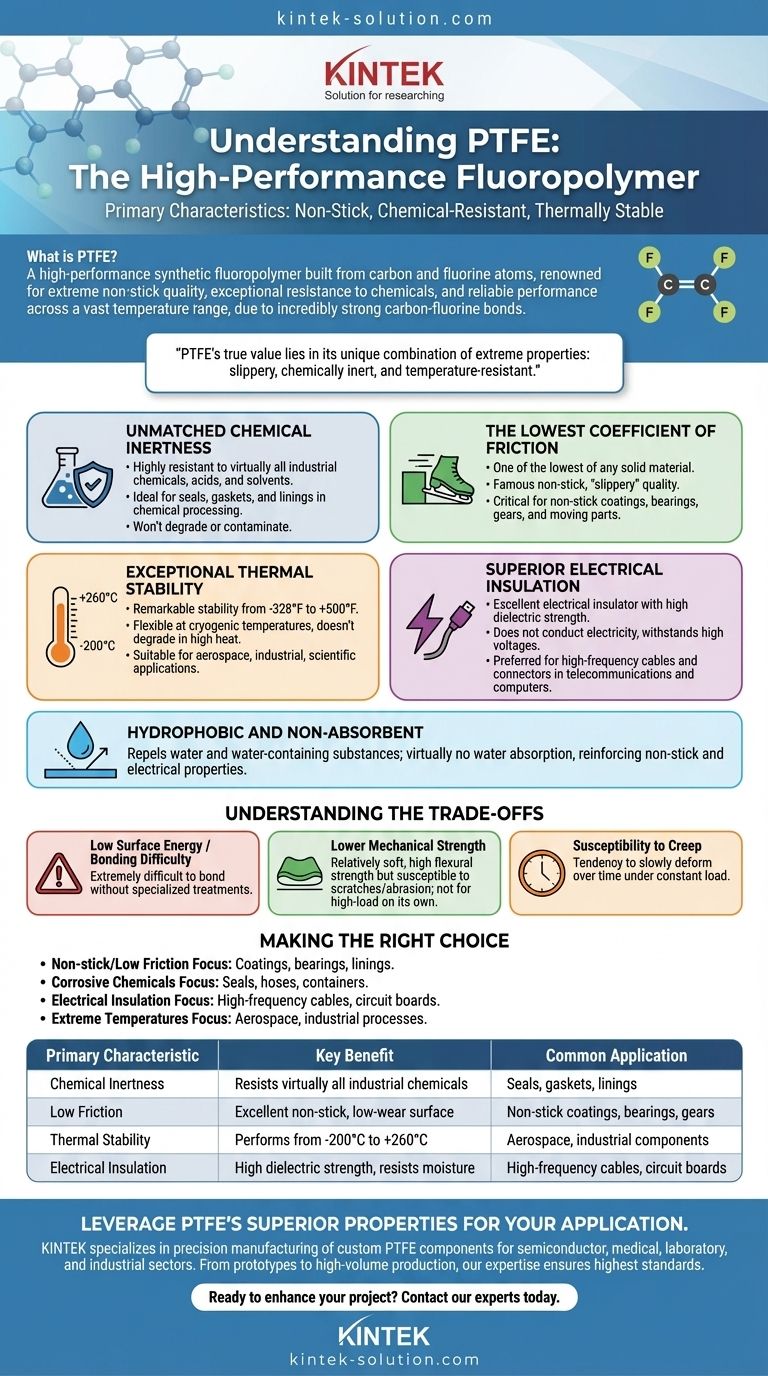

Polytetrafluoroethylene (PTFE) is a high-performance synthetic fluoropolymer built from carbon and fluorine atoms. It is most famous for its extreme non-stick quality, its exceptional resistance to nearly all chemicals, and its ability to perform reliably across a vast range of temperatures. These characteristics stem from the incredibly strong bond between its carbon and fluorine atoms.

While many materials excel in one area, PTFE's true value lies in its unique combination of extreme properties. Its incredibly strong carbon-fluorine bond makes it simultaneously one of the most slippery, chemically inert, and temperature-resistant materials available for engineering applications.

The Core Properties of PTFE Explained

To understand why PTFE is chosen for demanding applications, we must look at its primary characteristics individually. Each property makes it uniquely suited for specific challenges where other materials would fail.

Unmatched Chemical Inertness

PTFE is highly resistant to virtually all industrial chemicals, acids, and solvents. This is because its strong carbon-fluorine bonds are difficult for other chemicals to break.

This inertness makes it an ideal material for seals, gaskets, and linings in chemical processing, where it will not degrade or contaminate the substances it contacts.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This is the source of its famous non-stick, or "slippery," quality.

This property is critical for applications like non-stick coatings on cookware, but it is also essential for high-performance bearings, gears, and other moving parts that require minimal resistance.

Exceptional Thermal Stability

This material demonstrates remarkable stability across an extremely wide temperature range, typically from -200°C (-328°F) up to +260°C (500°F).

It remains flexible at cryogenic temperatures and does not degrade in high-heat environments, making it suitable for aerospace, industrial, and scientific applications involving extreme temperatures.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength. It does not conduct electricity and can withstand high voltages.

This makes it a preferred material for insulating high-frequency cables and connectors, particularly in the telecommunications and computer industries.

Hydrophobic and Non-Absorbent

PTFE is hydrophobic, meaning it actively repels water and water-containing substances. It has virtually no water absorption.

This property reinforces its effectiveness in non-stick applications and ensures its performance as an electrical insulator is not compromised by moisture.

Understanding the Trade-offs

No material is perfect, and PTFE's unique strengths create inherent limitations. Acknowledging these is key to using it effectively.

Low Surface Energy and Bonding Difficulty

The very property that makes PTFE non-stick—its low surface energy—also makes it extremely difficult to bond to other materials.

Standard adhesives will not work. Attaching PTFE to another surface requires specialized chemical etching or surface treatments to create a bondable layer, which adds complexity and cost.

Lower Mechanical Strength

Compared to engineering metals or even other high-performance plastics, PTFE is a relatively soft material. It has high flexural strength but can be susceptible to scratches and abrasion.

It is generally not suitable for high-load structural applications on its own, though it can be reinforced with fillers like glass or carbon to improve its mechanical properties.

Susceptibility to Creep

As a thermoplastic, PTFE can be prone to creep, which is the tendency to slowly deform over time when under a constant load. This must be considered in the design of components like seals and gaskets that are under constant pressure.

Making the Right Choice for Your Goal

Selecting PTFE depends on whether its unique benefits outweigh its limitations for your specific need. Use these guidelines to determine if it is the right choice.

- If your primary focus is a non-stick or low-friction surface: PTFE is an industry-leading choice for coatings, bearings, and linings where reducing friction is the main objective.

- If your primary focus is handling highly corrosive chemicals: PTFE's chemical inertness makes it the default material for seals, hoses, and containers in aggressive chemical environments.

- If your primary focus is insulating high-frequency electrical components: Its outstanding dielectric properties make it ideal for critical wire insulation and high-performance circuit boards.

- If your primary focus is operating in extreme temperatures: PTFE's ability to perform reliably in both cryogenic and high-heat conditions makes it suitable for demanding aerospace and industrial processes.

By understanding its distinct profile of properties and limitations, you can effectively leverage PTFE in the most demanding engineering challenges.

Summary Table:

| Primary Characteristic | Key Benefit | Common Application |

|---|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals | Seals, gaskets, linings in chemical processing |

| Low Coefficient of Friction | Excellent non-stick, low-wear surface | Non-stick coatings, bearings, gears |

| Exceptional Thermal Stability | Performs from -200°C to +260°C | Aerospace, industrial, scientific components |

| Superior Electrical Insulation | High dielectric strength, resists moisture | High-frequency cables, connectors, circuit boards |

Leverage PTFE's Superior Properties for Your Application

PTFE's unique combination of chemical inertness, low friction, and thermal stability makes it the ideal material for solving the most demanding challenges in the semiconductor, medical, laboratory, and industrial sectors. At KINTEK, we specialize in the precision manufacturing of custom PTFE components—from seals and liners to specialized labware.

Whether you need a prototype or a high-volume production run, our expertise ensures your components meet the highest standards of performance and reliability.

Ready to enhance your project with high-performance PTFE? Contact our experts today to discuss your custom fabrication needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What factors influence the coefficient of friction in PTFE materials? Optimize Performance for Your Application

- What are the recommended PTFE formulations for the chemical processing industry and why? Optimize for Durability and Chemical Resistance

- What are the dielectric properties of PTFE? The Ultimate Insulator for Demanding Applications

- What maintenance practices ensure optimal PTFE performance? Preserve Performance with Proven Care

- What is Expanded PTFE and how does it differ from regular PTFE? Choosing the Right Material for Your Application

- What is the coefficient of friction (COF) and why is it important? Master Efficiency, Longevity, and Control

- What are common uses of PTFE? Unlock Versatility for Your Industry

- In which industries can PTFE be used due to its hygienic properties? Ensure Purity and Safety in Food, Pharma, and Medical